Pellet heating is an excellent option for an autonomous

Modern heating boilers can work on many types of fuel, for example, on gas, coal, fuel oil, diesel fuel, conventional firewood, etc. When choosing a particular type of boiler, you have to solve a rather complicated task - the chosen type of fuel must be efficient and inexpensive, In addition, the heating system should be as autonomous as possible. The criteria listed fully correspond to the heating on pellets.

Pellets - the usual fuel in the new form

Despite the appearance, this is the most common wood fuel. Externally, 1 granule looks like a small cylinder about 5–70 mm long and 6–10 mm in diameter. The raw material for the production of such fuel is waste wood industry (conventional sawdust, bark, chips, etc.).

Note! Pellets for heating a small size (diameter 6-8 mm, and a length in the range of 30-50 mm) is best used for a boiler in a private house. But in industrial boilers, pellets with a diameter of more than about 10 mm are loaded, the working temperature in such boilers is higher, so small pellets will burn out too quickly.

The production process is quite simple, this can explain the low cost of the granules.

Production is carried out according to the following scheme:

- The waste of the woodworking industry is cleaned of dirt and sand and is pulled under a strong magnet, which removes possible metal particles from them;

- then the pulp is ground and dried to a moisture content of about 12%. At this stage, the maximum size of wood particles should not exceed 4 mm;

- after that there is a stage of repeated (fair) crushing and drying already to a moisture content of about 10%;

- The resulting mass enters the granulator, in which pellets for heating are formed under high pressure (and in some cases, by elevated temperature). The principle of operation resembles a large meat grinder - the mixture is pressed through a disk with holes, therefore the shape of the granules is cylindrical.

Types of pellets

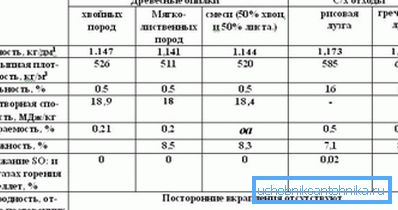

The properties of a particular type of granules depend on their composition, because not only sawdust and chips can be used for production, but also hay, straw, palm leaves, peat, etc.

If pellet heating is planned, then special attention should be paid to the ash content of the selected type of fuel, such pellets can be identified as:

- premium class can be distinguished by the white color of the granules. This type of fuel is characterized by low ash content, as a rule, this indicator does not exceed 0.7%. The price, of course, exceeds the cost of other types, but the boiler is guaranteed to work without problems;

Note! Low ash does not mean that you can forget about cleaning the ash pan. It will be necessary to clean the boiler much less frequently, approximately once every 1.5-2 months (depending on the intensity of the boiler operation).

- industrial class - the main difference is that in the production not only wood is used, but also bark, this increases the ash content of the fuel, which can reach 1.5%. Such pellets can also be used for heating a private house, but you need to carefully monitor the operation of the boiler and regularly clean the ash pan; (See also the article Electric heating convectors: features.)

- agropellets - definitely not the best choice for heating a private house. The cost, of course, is minimal, but the ash content is 10-20 times higher than that of the listed types of pellets (reaches 10%).

More about pellet heating

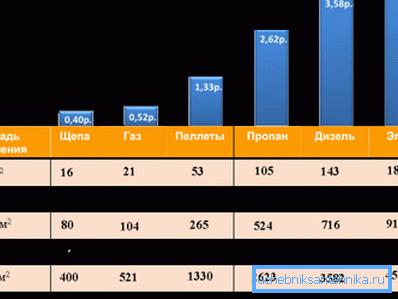

Heating with pellets can be attributed to one of the inexpensive ways to heat a dwelling. Strictly speaking, it is inferior in price to gas heating, but a number of advantages outweigh this disadvantage. (See also the article Wall-mounted gas heating boilers: features.)

The strengths and weaknesses of the heating pellets

The list of advantages of this type of fuel is quite impressive and includes:

- increased calorific value compared to conventional firewood. On average, when burning 1 ton of pellets corresponds to 685 liters of fuel oil or 50o liters of diesel fuel, but wood to get the same energy will have to burn 1.6 tons;

- absolute safety during storage;

- stable cost - gas for the population in the future may become more expensive, but pellets are unlikely to rise sharply in price;

- heating of a country house with pellets can be called truly autonomous - it does not depend on the gas supply;

- during combustion into the atmosphere no harmful chemicals are released, because the granules are produced without the use of chemical additives;

- pellets allow you to automate the process of supplying fuel to the combustion chamber of the boiler.

There are not so many disadvantages and it is impossible to call them critical:

- the stock for winter requires quite a lot of storage space;

- in the warm season it is necessary to control the humidity in the place of storage of fuel;

- the cost of the boiler for such fuel exceeds the price of electric and gas analogues.

Heating boilers for pellets

The boilers, allowing to organize the heating of a private house with pellets, are divided into several types:

- intended exclusively for pellets;

- models in which it is allowed to burn firewood for a short time;

Note! Burning wood in such devices should be considered as an extreme measure. For example, the supply of pellets is over, but the new lot has not yet been brought up.

- models in which the manufacturer laid the possibility of using 2 types of fuel. In them the transition from wood to pellets is possible at any time.

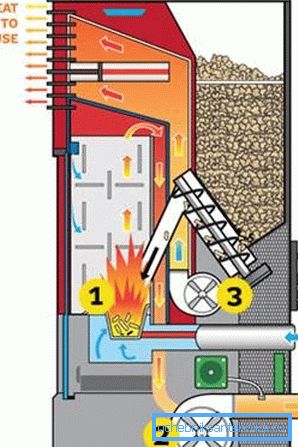

An important advantage of boilers of this type is that they allow you to organize automatic heating on the pellets. Such systems operate with little or no human intervention; pellets are loaded into the bunker (the volume of the bunker is several cubic meters).

In the future, as the pellets burn through the bunker, new fuel is automatically fed into the furnace. Thanks to this fuel reserve, the boiler will work for several days without “refueling”.

From manual labor, it is possible to note the cleaning of the ash pan, but this operation is unlikely to be carried out more often 1-2 times a month. For comparison - in the boilers running on conventional wood, the fuel has to be thrown much more often, and the ash to clean

Pellet fireplaces

If the area of the house is small, then it makes no sense to acquire a powerful boiler, it is much more profitable to stay on the fireplace. In this case, in addition to saving in price, the installation of the device will also be facilitated, it can be guaranteed to be done with your own hands.

It is more profitable to use a fireplace in the case when the power of the heater according to calculations should be less than 15 kW. If you only need heating of rooms, then the convection boiler can be considered the best choice (it heats only air), and if necessary, models with the ability to connect a water circuit can also provide hot water.

The principle of operation is the same as in the boiler - a constant temperature condition is maintained in the furnace, and the heated gases are used to heat the dwelling (and to heat water in the heat exchanger).

Such fireplaces are quite simple to install, the installation instructions consist of several points:

- a non-combustible stand is installed on the floor;

Note! The stand should be at least 70 cm larger than the size of the fireplace in the plan.

- heat reflectors are installed on the walls;

- chimney is laid.

Compared to boilers, the fireplace, of course, is not equipped with such a massive fuel bunker. Therefore, it is necessary to replenish the stock of granules much more often.

Summarizing

Heating a house with pellets is quite an economical and efficient way to heat a dwelling, especially if there is no centralized gas supply. By all measures, this type of fuel exceeds the usual wood, only slightly inferior to gas heating.

Given the solid list of advantages and the almost complete lack of disadvantages, pellets can be considered an excellent choice for heating a country house.

The video clearly shows the process of a compact fireplace on pellets.