Pipe for underfloor heating: how to choose the optimal

The construction market offers different types of pipes used to create floor heating systems. When choosing them, the price of the material, the difficulty of working with it, the length of the service period are of particular importance. For warm floors, alumoplastic pipes are most often used, as well as polymer counterparts made from PEX (cross-linked polyethylene) or polypropylene.

A great option would be the copper system. However, this material is used infrequently, since the cost of a pipe for a warm floor made of copper is quite large.

Features of the underfloor heating system

The principle of operation of water systems is quite simple. Special pipes are laid under the floor surface. They heat the floor, and from it warm air rises into the room (read also the article Selection and laying of pipes for a heated floor: installation features of the heating system).

Note! Thanks to the design of the system, heat is distributed evenly throughout the volume of the room. Draft, characteristic for radiator heating, are not created.

Installation of water networks, as a rule, is carried out in toilets, kitchens, bathrooms, etc. Most often for the flooring is chosen ceramic tile, which has good thermal conductivity.

Advantages and disadvantages

Choosing a pipe floor heating system, you should consider all its pros and cons.

The following are the main advantages of the design:

- The entire area of the room is heated evenly.

- Metal pipes for floor heating and other elements of the system are masked under the topcoat.

- It is possible to heat volumetric rooms at low power consumption.

- Environmental friendliness of the system - electromagnetic emissions and harmful emissions are absent.

- You have to spend money only once - to install the network. The cost of its operation is minimal.

Of the minuses can be noted the following:

- The need to use a water pump.

- The complexity of the installation system.

- It is difficult to regulate the heating temperature of the rooms.

- Sometimes the pressure in the riser decreases, and because of this, the neighboring apartments are heated worse.

- A small chance of leakage that is difficult to find.

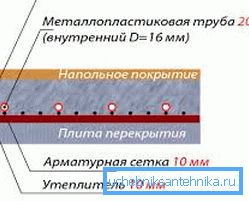

- The system thickens the “cake” of the floor by at least 8/10 cm.

- The instruction warns that some time is needed for testing events and launching the network.

Pipe selection

- Floor heating systems use polybutene, polyethylene, aluminum plastic, copper, steel and polypropylene pipes. The regulations prohibit the use of black iron and suture varieties only.

- The optimum outer diameter of the elements of the system is 16-18 mm. The thickness of the floor with such a parameter will not increase very much, and additional devices will not be needed for effective hydraulics.

Note! After laying pipes are filled with a coupler. If they are damaged, the cover will have to be opened. On this basis, plastic pipes for underfloor heating should be extremely reliable.

- All joints of the system should be made hermetic by 100%, and its individual elements should have protection preventing oxygen diffusion.

- The coefficient of linear expansion of the material should be less than 0.025 mm / mK, thermal conductivity - from 0.43 W / mK.

- In one room should be laid pipe coils, consisting of a single cut of the bay.

- The service life of the material should be comparable to the life of the facility.

PEX pipes

- Pipes of cross-linked polyethylene have increased resistance to thermal stress. This makes it possible to raise the temperature of the heat carrier.

- Increased strength of the material is achieved through the use in the production of high pressure.

- Flexible PEX pipes for underfloor heating have different densities. The optimal density of crosslinking varies in the range of 65-80%. This parameter determines the price of products.

- Polyethylene can be processed in several ways. Using silane gas (crosslinking density — 65%), peroxide (75% indicator), irradiating PE with an electron beam in a magnetic field (density 60%).

Crimped fittings are used to get the tight and durable pipe mate with your hands. The connection takes only a few seconds.

It happens like this.

- A compression ring is put on one side of the joint.

- Further, a special device expands the pipe section.

- In the enlarged pipe fitting is installed.

- At the final stage, the pipes are firmly crimped with a ring around the fitting.

PEX pipes are optimal for underfloor heating systems. However, knowing how much the network of them costs, many homeowners prefer metal-plastic counterparts, since they are cheaper.

Metal-plastic analogues

When heated, aluminum-plastic products retain their original structure, can resist impressive loads, their service life is very long. Products consist of five layers.

Three layers - the main two remaining glue them together, that is, they are binding. Inside and on the surface of the pipe is cross-linked polyethylene or polypropylene. In the center of the product - aluminum foil.

It also connects to plastic with glue.

- The inner layer is responsible for the working properties of the product, concerning temperature and pressure.

- Then there is a layer of special adhesive component. It provides reliable coupling of the polymer to the central part of the metal.

- A special foil is used to produce this aluminum layer. Its thickness, based on the section and variety of pipes, ranges from 0.2 to 2.5 mm.

- This part of the product is welded along its entire length using two methods - overlap or end-to-end.

- Next is the second layer of adhesive. It holds the metal with the outer protective surface of the product.

- The outer layer of the pipe is made of polyethylene, having a cross-linked structure or ordinary, but with high density. Also produced products from different grades of polypropylene.

- Due to this structure, alumoplastic pipes have good flexibility, resistance to deformation and thermal plasticity. This is especially important when arranging underfloor heating.

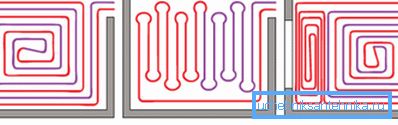

Note! The heat-insulated floor from metalplastic pipes needs to be mounted in the form of rounds, spirals, snakes. This structure of the system has a large number of turns. At the same time, a relatively small mass of products greatly facilitates the workflow.

How to calculate pipe flow

- When planning the arrangement of water heated floors in a particular room, it should be borne in mind that the length of the coil of special pipes can be no more than 100 meters. In this case, a separate circuit (loop) of the network must be laid out of the whole product.

- Experts say that a bay of 100 meters is enough for you to warm a room of 20 square meters.. Knowing the total volume of the room, it is possible to calculate how much pipe is needed per m2 of heated floor.

- When making calculations, do not forget to subtract from the amount of the required material areas (under pieces of furniture, household appliances, etc.) on which the pipes will not be laid.

- When designing a floor heating system, you should take into account the distance, called the pitch, which must be left between adjacent hinges.. Its value is dependent on the level of temperature at the site of installation of heated floors. The maximum step should be 30-35 cm.

- If it is larger, users will feel temperature drops, because the surface of the finishing coating will not be evenly heated.

Conclusion

The best option is to use polymer products for floor water heating systems from pipes. This modern and reliable products can be solid or have a protective and reinforcing layer of aluminum.

The video in this article will help you understand the additional information.