Polycarbonate greenhouse heating - own tomatoes, no need

To receive fresh vegetables and greens all year round in greenhouse conditions is possible only at a positive temperature. The solution to this problem lies in the correctly chosen covering material and proper heating. And if polycarbonate is recognized by the majority of votes as the most successful external protection against the vagaries of weather, then everyone has to decide the microclimate inside the greenhouse individually.

Science in agricultural masses

Difficult stages of chemical production were crowned once with the release of a polycarbonate that is unique in its properties. One of the first advantages of the material was appreciated by industrious Jews, perfecting agriculture in the deserts in the early 70s of the last century.

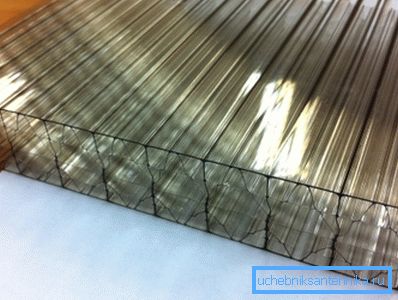

Cellular polycarbonate, created a little bit later, without being distraught, can be called an ideal option for greenhouse farming due to:

- ease - with the same sheet thickness, it is 16 times lighter than glass;

- light transmission up to 85%;

- plasticity, which is important during installation;

- durability, provided the correct device frame;

- toughness, and simpler strength;

- flame retardant;

- self-extinguishing;

- sound insulation;

- thermal insulation due to the air gap - honeycomb;

- temperature - from -40 to +120 ° C resistance.

To the greenhouse stood for a long time

In order to preserve the properties of the covering material promised by the manufacturer, it is necessary to create for this condition, namely, a reliable framework. For this, aluminum profiles with a cross section of 200x200 mm and a thickness of 1.5 mm using reinforcing elements are well suited.

The profiles are made of arched stiffeners in 1 m increments. The streamlined shape of the finished structure resists to the winds and there is very little chance that polycarbonate sheets will hang in bags or the greenhouse will be under the weight of snow cover.

The manufacturer's instructions may advise to stick the ends of the arches into the ground, which is the height of stupidity:

- the greenhouse may fly away;

- construction loses in height.

It is worth spending time and money on a good concrete, brick, or at least a foundation of impregnated timber on a substrate.

Spending time building the base, you get:

- safety of the bearing elements;

- additional heat insulation;

- protection of structures against deformation.

With warm care

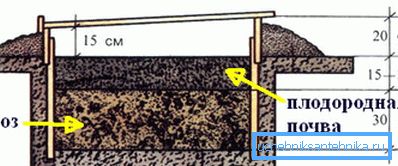

Before the greenhouse heating device it is necessary to take measures to prevent the loss of heat, which is precious for the garden flora. After laying the foundation, a simple but effective measure will be to fill the trench around the perimeter with expanded clay gravel.

Porosity and thermal insulation properties of expanded clay will significantly increase the thermal insulation of the internal space and will not allow the ground to freeze. For the spring greenhouse, a trench is being dug 20 feet deep and 10 cm wide, for year-round it is dug in from 70 to 100 cm with a width of 25–30.

Protect the claydite layer from the soil with a strip of ruberoid or plastic, and sprinkle it on top with a thin layer of earth to avoid disturbing the dumping. So you get the insulation and drainage at the same time, protecting the plants from harmful moisture from above.

Bio-classic

Small areas can be heated with biofuel based on horse manure, which has the highest efficiency. Due to the shortage of horses, dung of cows, goats, rabbits, sheep, which is added to sawdust, straw, leaves or household food waste, will fit.

Living fuel is put in ditches with a layer of 40–70 cm and powdered with sawdust, peat, and earth. Under the action of microorganisms, organics decompose, releasing carbon dioxide needed by plants. But as the sole source of heat, this option is not suitable due to insufficient heat.

Note! Manure settles and every few days you need to pour a new batch for the heap to work.

Green house heat supply

Normal development and fruiting plants require warm air and soil.

To do this, in the arsenal of man there are many ways similar to those with which he creates comfort in his own house.

- Heaters - mobile devices with a fan, ensuring good circulation of warm air masses. Built-in thermostats help to set up and maintain the necessary microclimate. Air drying is their main drawback.

- When choosing convectors / convection systems that uniformly heat the air, one should not forget about the difficulties of adapting the convectors to the greenhouse conditions. The second negative point is the poor heating of the soil.

- Water as a heat carrier can create normal conditions for the development of garden crops.. The disadvantage is the mandatory participation of specialists in the installation and the subsequent constant monitoring of the operation of these systems.

- The use of natural energy through air-to-air, ground-to-water, water-to-water, and water-to-air pumps will provide good yields.. It is advisable to use in year-round greenhouse. In this case, the high price of the unit can quickly pay off.

- Infrared lamps located directly next to the plants - an example of frugality and benefits. The lamps also heat the ground, the supporting structure, the walls, which, in turn, also begin to radiate heat. Installing a system of lamps, by analogy with the "smart home" will allow in automatic mode to control the amount of heat, the microclimate.

- Air heating is carried out with the help of heating fans, which are installed in the middle and upper level of the structure.. A perforated PE sleeve is laid along the perimeter on the ground, through which heat circulates. As a result, the earth and air warms up, not over-drying the leaves.

- The use of gas implies the existence of a gas burner system operating directly in the room.. It is advisable to connect large greenhouse areas to the gas mains, which you cannot do with your own hands. The second disadvantage is the necessary paperwork for the connection.

Note! A long burning process can "eat" all the oxygen, which can lead to poisoning of both plants and people. It is necessary to ensure the availability and continuous operation of the ventilation.

- Cable heating will allow to equip the "warm floor" in the earthen version and warm the walls of the building. It is better to trust the experts who calculate the temperature, sparing the root system.

- Heating with high efficiency buleryan, ensuring safe heat, because the walls of the boiler do not heat up.

Summarizing

Diligence multiplied by the use of modern technologies in the field of greenhouse, may surprise with a rich harvest at any time of the year. The advantages of cellular polycarbonate and a well-designed heating system will help turn seasonal work into the life of your life.

The video shows a variant of the infrared heating of the greenhouse.