Pressure drop in the heating system: functions, values,

What creates the pressure drop in heating and water supply systems? What is it for? How to regulate the differential? What are the reasons why the pressure in the heating system drops? In the article we will try to answer these questions.

Functions

First, find out why a drop is created. Its main function is to ensure the circulation of coolant. Water will always move from a point with high pressure to a point where the pressure is less. The more difference - the more speed.

Useful: the hydraulic resistance increases with limiting flow rate and becomes the limiting factor.

In addition, the difference is artificially created between the circulating hot-water tie-ins in one thread (supply or return).

Circulation in this case performs two functions:

- Provides consistently high temperature towel warmers, which in all modern houses open one of the connected GVS risers in pairs.

- Guarantees fast hot water to the mixer regardless of the time of day and water analysis on the riser. In old houses without circulatory inserts, water in the morning has to be drained for a long time before it is heated.

Finally, the drop is created by modern water and heat metering devices.

How and for what? To answer this question, you need to refer the reader to the Bernoulli law, according to which the static pressure of the flow is inversely proportional to the speed of its movement.

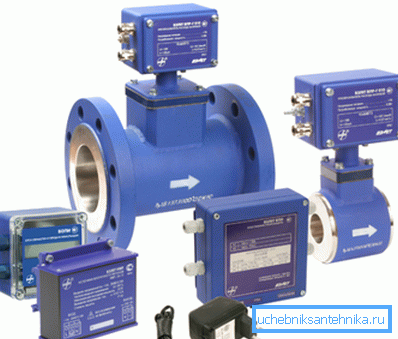

This gives us the opportunity to design a device that records the flow of water without using unreliable impellers:

- We skip the flow through the cross section.

- We register the pressure in the narrow part of the meter and in the main pipe.

Knowing the pressure and diameters, with the help of electronics, you can calculate in real time the flow rate and water flow; when using temperature sensors at the entrance and exit from the heating circuit, it is easy to calculate the amount of heat remaining in the heating system. At the same time, the consumption of hot water is calculated by the difference in flow in the supply and return pipelines.

Create Delta

How is the differential pressure created?

Elevator

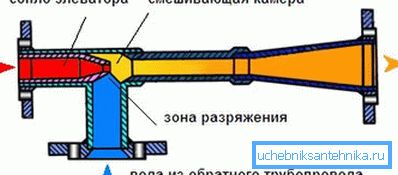

The main element of the heating system of an apartment building is an elevator unit. Its heart is the elevator itself - a nondescript pig-iron tube with three flanges and a nozzle inside. Before explaining the principle of the elevator, it is worth mentioning one of the problems of central heating.

There is such a thing as a temperature graph - a table of the dependence of the temperature of the supply and return routes on weather conditions. We give a short excerpt from it.

| Outdoor temperature, C | Giving, With | Return, With |

| +five | 65 | 42.55 |

| 0 | 66.39 | 40,99 |

| -five | 65.6 | 51.6 |

| -ten | 76.62 | 48.57 |

| -15 | 96.55 | 52.11 |

| -20 | 106.31 | 55,52 |

Upward and downward deviations from the graph are equally undesirable. In the first case, the apartments will be cold, in the second - the cost of energy in a CHP or boiler room rises sharply.

At the same time, as it is easy to notice, the spread between the flow and the return pipeline is large enough. When the circulation is sufficiently slow for such a delta of temperatures, the temperature of the heaters will be unevenly distributed. Residents of apartments whose batteries are connected to the supply pipes will suffer from the heat, and the owners of radiators on the return line will freeze.

The elevator provides partial recirculation of the coolant from the return pipeline. By injecting a quick stream of hot water through the nozzle, in full accordance with Bernoulli’s law, it creates a fast flow with low static pressure, which draws additional water through the suction.

The temperature of the mixture is noticeably lower than that of the feed, and slightly higher than on the return pipeline. The circulation rate is high, and the temperature difference between the batteries is minimal.

Retaining washer

This simple device is a disk of steel with a thickness of at least a millimeter with a hole drilled in it. It is placed on the flange of the elevator assembly between the circulation inserts. Washers are placed on both the supply and return pipes.

Important: for normal operation of the Elevator Assembly, the diameter of the holes of the retaining washers must be greater than the diameter of the nozzle. Usually the difference is 1-2 millimeters.

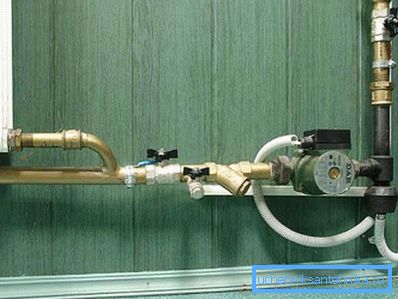

Circulation pump

In autonomous heating systems, the pressure is generated by one or several (by the number of independent circuits) circulation pumps. The most common devices - with a wet rotor - are a structure with a common shaft for the impeller and the rotor of the electric motor. The coolant performs the functions of cooling and lubrication of bearings.

Meanings

What is the pressure drop between different parts of the heating system?

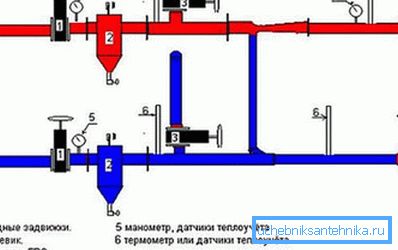

- Between the supply and return lines of the heating main, it is about 20–30 meters, or 2–3 kgf / cm2.

Reference: excess pressure in one atmosphere raises the water column to a height of 10 meters.

- The difference between the mixture after the elevator and the return pipeline is only 2 meters, or 0.2 kgf / cm2.

- The drop on the retaining washer between the circulation inserts of the elevator assembly rarely exceeds 1 meter.

- The pressure generated by a wet rotor circulating pump usually varies from 2 to 6 meters (0.2 - 0.6 kgf / cm2).

Adjustment

How to adjust the head in the elevator assembly?

Retaining washer

To be precise, in the case of a retaining washer, it is not necessary to adjust the pressure, but to periodically replace the washer with a similar one due to the abrasive wear of the thin steel sheet in the process water. How to replace the puck with your own hands?

The instructions are generally quite simple:

- All valves or valves in the elevator overlap.

- Opened by one dumper on the return and flow for the drainage site.

- Unscrew the bolts on the flange.

- Instead of the old washer, a new one is installed, equipped with a pair of gaskets - one on each side.

Tip: in the absence of paronite washers cut out of the old car camera. Do not forget to cut the eyelet, which will allow to get the puck into the groove of the flange.

- Bolts in pairs, crosswise. After the gaskets are pressed, the nuts are tightened to the stop by no more than half a turn at a time. If you hurry, uneven compression, sooner or later, will cause the gasket to vomit pressure on one side of the flange.

Heating system

The difference between the mixture and the return flow is regularly regulated only by replacing, brewing or reaming the nozzle. However, sometimes there is a need to remove the differential without stopping the heating (as a rule, with serious deviations from the temperature graph at the peak of cold weather).

This is done by adjusting the inlet valve on the return pipe; thus, we remove the difference between the direct and reverse threads and, accordingly, between the mixture and the return.

- We measure the pressure at the flow after the inlet valve.

- Switch the DHW to the feed line.

- Screw the pressure gauge into the discharge pipe on the return pipe.

- Fully close the input return valve and then gradually open it until the drop decreases from the initial one by 0.2 kgf / cm2. Manipulation with closing and subsequent opening of the valve is necessary in order to maximize its cheeks on the stem. If you just cover the valve, the cheeks can subside in the future; the price of a ridiculous time saving is at least unfrozen access heating.

- The temperature of the return pipe is monitored at intervals of 24 hours. If necessary, to further reduce the differential is removed at 0.2 atmosphere at a time.

Offline pressure

The immediate meaning of the word differential is a change in level, a fall. Within the framework of this article we will touch upon him. So, why does pressure drop in the heating system if it is a closed loop?

First, remember: water is almost incompressible.

Excessive pressure in the circuit is created due to two factors:

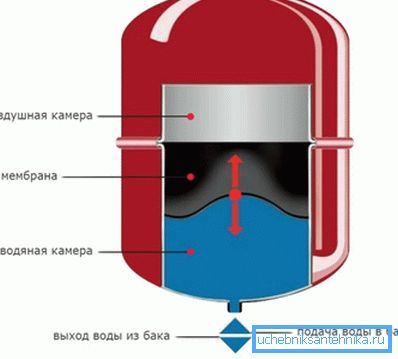

- The presence in the system of membrane expansion tank with its air cushion.

- The elasticity of pipes and radiators. Their elasticity tends to zero, but with a large area of the inner surface of the contour, this factor also affects the internal pressure.

On the practical side, this means that the pressure drop recorded by the manometer in the heating system is usually caused by an extremely small change in the volume of the circuit or a decrease in the amount of coolant.

And here is a possible list of both:

- When heated, polypropylene expands more than water. When starting a heating system assembled from polypropylene, the pressure in it may drop slightly.

- Many materials (including aluminum) are sufficiently plastic in order to change shape with moderate pressure. Aluminum radiators can simply swell with time.

- The gases dissolved in water gradually leave the circuit through the air vent, affecting the actual volume of water in it.

- Significant heating of the heat carrier when the volume of the expansion tank for heating is too low may trigger the safety valve.

Finally, quite real faults cannot be ruled out: minor leaks along the joints of sections and weld seams, a pickling nipple in the expansion tank and microcracks in the boiler heat exchanger.

Conclusion

We hope that we were able to answer the questions that have accumulated in the reader. Attached to the article video, as usual, will offer him the attention of additional thematic materials. Successes!