Pressure testing of the heating system: purpose, features,

Pressure testing and flushing of the heating system is a mandatory procedure prior to the commissioning of the heating. At the end of the procedure, a test certificate form is completed, which is a mandatory document indicating the successful installation of the heating network.

We will tell you what is heating heating and how it should be done.

Pipeline Hydraulic Test

Definition and procedure

Pressure testing and flushing of heating systems is a necessary procedure, which consists in the hydraulic testing of an object for the presence of leaks and poor quality connections. The test is that the pipeline is filled with water, the air is removed with the help of air vent valves and the equipment for pressure testing the heating system is connected (see also the article Meet - Air Heating Systems).

The compressor injects pressure, which is 20–50% higher than the rated operating one, and the pipeline is left in this state for 30 minutes. During this time, the pressure is controlled by a pressure gauge, and if it does not fall, it means that the network is tight. New modern heating circuits are tested with double excess of working pressure.

If, however, a pressure drop is recorded within 30 minutes, then the press to pressurize the heating systems is turned off, the water is drained, and all parts of the heating are checked for leaks. When the leak is found and fixed, the procedure is repeated.

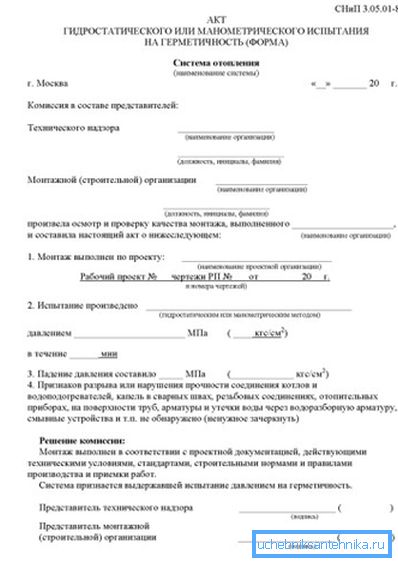

At the end, on the basis of the work done, an estimate is made for the crimping of the heating system, which indicates the cost of each individual phase of work and the cost of the measure as a whole (according to OKDP - “4530195 Test hydraulic and pneumatic pipelines”), as well as a pressure test.

Note! After a successful test, the inspector draws up an act of pressure testing, which is signed by the representative of the installation organization and a representative of the technical supervision. Upon completion, the object is flushed and put into operation.

Equipment and personnel for pressure testing

A classic example of equipment for conducting hydraulic testing is a heating press. This device is connected to the circuit for a controlled increase in pressure in the pipes.

The pump for pressure testing of heating systems can be manual or electric. Since for most local heating networks of private houses and high-pressure cottages are not required, manual pressure testing is quite enough.

Manual pumps for pressure testing of heating systems can develop an effort from 25 to 60 bar or more, which is quite enough to check the tightness not only in a country house, but also in a city five-story building.

The advantages of using handheld devices:

- The small size and weight of the device makes it mobile even in a normal city apartment. The manual pump will be convenient both for professional activity, and for personal use;

- The relatively low price of equipment makes it affordable for the general public.. Unlike specialized electrical equipment, manual presses have quite affordable price tags;

- The range of operating parameters fully meets the needs of small and medium-sized heating equipment.. The pump allows you to achieve double the operating performance of the normal network of a private house;

- Simple design is highly reliable and long-lasting without breakdowns and failures.. The pump is very simple, and there’s nothing special about breaking it.

For testing large and extensive circuits at large sites, multi-storey buildings, manufacturing plants, etc. use electric pumps that pump water under high pressure, unattainable for manual mechanisms. They are equipped with a self-priming pump and are capable of developing a force of up to 500 kgf / cm2 (bar).

Electrical units can be built into the line or connected to any hole. Most often, the hose is connected to a drain valve or tap through which the pipe is filled with water. Also practiced connection to the radiator through the connector for the crane Mayevsky.

Electrical machines are usually equipped with a control unit with automatic protection against overheating. If the engine temperature rises above the preset limit, then the protection releases pressure and allows the unit to rest.

For small networks, typical for country houses and other small buildings, the level of effort is lower - up to 2 atm. Such networks can be checked with the usual water pressure. The heating pipeline is connected to the central water supply network, a pressure of about 2 kgf / cm2 arises in it, and then the object is inspected for leaks and other defects.

Note! If you installed the heating in the country with your own hands, then you can cope with the test without the help of specialists. But in the case of urban high-rise buildings, the instruction requires the mandatory participation of utilities and services that perform maintenance of the facility.

The representative of the technical supervision or the representative of the customer of the works accepts the works.

In what cases make pressure testing

It remains to find out when it is necessary to test the pipe for strength.

According to the provisions of the SNiP, verification is performed in such cases:

- After mounting a new object. To put the heating into operation, it is necessarily tested with high pressure;

- After repairing any part of the network or any heating device, fittings, equipment. Any depressurization requires re-testing;

- After replacing any part of the pipeline, after the elimination of any violation of the integrity of the pipes or poor-quality connections;

- Before the start of the heating season.

Note! Before you pressurize the heating system, outsiders and residents should be evacuated from the premises. For safety reasons, work is performed on an empty object.

Conclusion

We reviewed the heating pressure test and told what it is. If you are interested in more detailed information, watch the video and read other materials on our site.