Pumps for heating: how to choose electrical equipment for

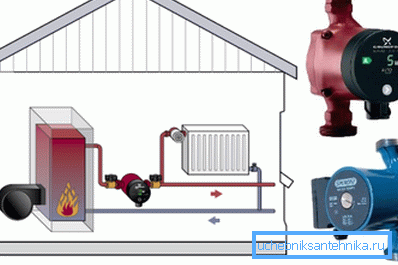

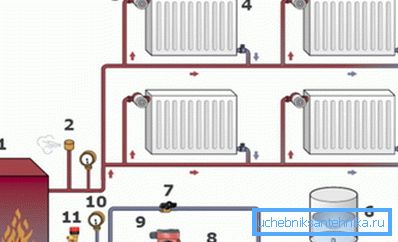

In modern construction, heating schemes with forced circulation of coolant are gaining more and more popularity. One of the main elements of this engineering network is a pump for heating. If you decide to design such a climate system with your own hands, but do not know which equipment to prefer, where to put the electric pump and how to calculate its power, we recommend that you familiarize yourself with the material outlined below.

Principle of operation of the device

Answering the question whether you need a pump for a heating system — in order to organize a direct current of the coolant or to feed a gravity climate network — many factors need to be taken into account.

One of the main ones is the heated area and the number of floors of the house. If we are talking about a small dacha, natural circulation is enough. But when your house building has more than 200 square meters. meters of total area or has three or more floors - the heating pump is a must.

The pressure of the coolant in the gravitational system does not exceed 0.6 MPa, which is clearly not enough to provide high-quality heating of the whole house. The installed pump for the heating system makes it possible to organize an efficient distribution of heated water or antifreeze over all radiators, no matter how far from the boiler they are.

According to the principle of operation, domestic and industrial circulation pumps for climate networks are similar to drainage installations.

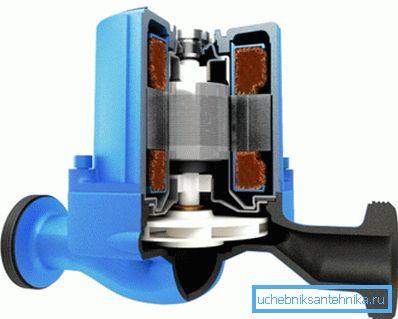

They consist of the following elements:

- cases - as a rule, it is made of stainless steel to avoid corrosion;

- rotor - it is often made of ceramics for the same reasons;

- shaft - it is wearing a wheel with blades, which provides a stream of water or other fluid in the pipes.

Torque rotor reports the electric motor. The vanes pick up the fluid supplied through the inlet and push it into the outlet. In this way, it is possible to overcome the hydraulic resistance that occurs in difficult sections of pipes and ensure the supply of coolant to all elements of the heating system.

The advantages of equipment

In modern specialty stores sold various pumps for heating systems. They are distinguished from each other by the price, operating voltage (220 or 12 volts) and other technical characteristics.

However, regardless of the type, model and modification, heating with a pump has many advantages. The most important features of such structures are presented in the table.

| Feature | Description |

| Reducing the inertia of the heating system | Pumps for the heating system allow to pump the heated coolant through all radiators in the shortest time possible. Therefore, after a few tens of minutes after starting the boiler in all rooms of the house, the temperature will rise to a comfortable level. Heating without a pump will warm up the house for at least a few hours, or even more. |

| High efficiency | Due to the use of the described equipment, unproductive losses of thermal energy in pipelines and other network elements are minimized. As a result, the efficiency of the heating system increases. It is only necessary to correctly calculate the pump for heating. Otherwise, the devices you purchased will work in vain, consuming expensive electricity. |

| Reliability | All manufactured device models are as simple and reliable as possible. If the unit’s wiring diagram is followed and its periodic maintenance is correctly performed, you will hardly ever need to repair the heating pump. In addition, if faults are detected in the pump, the manufacturer (DAB, Grunfos, Wilo) will replace it free of charge. |

| Unpretentious operation of heating | Having installed a pump for the heating system, it is not necessary to observe the slope of the pipes, which is mentioned in the instructions for the design of a gravity heating network. Also, pumping electrical equipment makes it possible to equip the radial scheme of the climate network. Regardless of the configuration and length of the pipes, the fluid flow will always occur. |

Even if you are designing a gravity heating system, you can install an additional heating pump that will increase network performance if necessary (for example, when the outside air temperature is too cold).

Note! Heating systems with a circulating pump are volatile. That is, they will work only when electricity is supplied to the house. In order not to freeze in the event of wire breaks or power outages, it is recommended to install a battery-powered UPS for the heating pump, which will allow the latter to function for a while. If in your village often there are power outages, help out a diesel generator. Such a pumping station for heating will be completely autonomous.

Pump Types

Equipment "dry" type

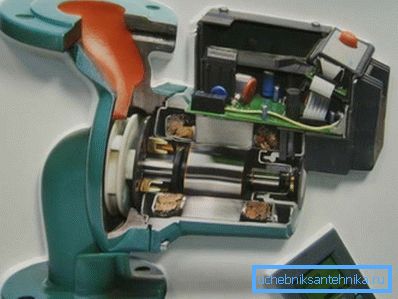

As the name implies, a feature of such pumps is that the rotor pumping fluid does not come into contact with it. The working body of the unit is separated from the electrical part by special sealing gaskets, which are carefully polished and adjusted to prevent leakage.

A dry heating pump has a very high capacity, but due to the presence of seals it produces a lot of noise during operation.

During its operation it is also necessary to take into account the following features:

- A dry pump can be installed only in a separate room - the boiler room. Otherwise, vibration and noise will make it uncomfortable to find people in the room where it is mounted.

- During operation, the rotor creates air turbulence around the pump jacket. They raise dust, which can get inside the device and break the tightness of the sealing rings.

To avoid this, it is necessary to maintain cleanliness in the boiler room and acquire models of pumps with a special hydraulic layer - a film of water between the seals, which traps dust particles and prevents them from coming into the rotor.

Dry type heating pumps are divided into several types:

- vertical - in this type of equipment the motor shaft is located vertically (such units are used in cases when it is necessary to pump a large amount of coolant);

- cantilever - a pipe supplying water, located on the outer side of the "snail", and the outlet - on the diametrically opposite end of the body;

- block - the water enters the pump in the direction of its axis, and is displayed radially.

Wet equipment

The peculiarity of this type of pump is that the rotor and the blades are washed by the coolant, which is pumped through the system. In this case, the electric motor itself is separated from the working body with a special glass filled with lubricant, which does not allow water or antifreeze to fill the electrical part of the device.

A “wet” pump into the heating system is installed if the length of the pipelines and the number of radiators is small. It is suitable for small houses, villas and city apartments.

Despite the small power, the described unit has many other advantages:

- works almost silently;

- does not require complicated maintenance;

- easy to repair;

- with its help it is easy to change the operating parameters of the heating network.

The most important disadvantage is a small efficiency. This is due to the fact that it is structurally impossible to increase the rotor speed and at the same time to ensure an adequate level of sealing of the glass.

Tip! Whatever heating pumps you install in your home, make sure they have an electronic control circuit for operating modes. So you can combine all the climatic equipment into a single network and manage it from one control panel. This allows not only to achieve the most comfortable conditions in the house, but also significantly save on energy costs.

Selection of pumping equipment

Calculation of technical parameters

It is necessary to choose a specific type and power of the pump for the heating system, taking into account its technical characteristics and features.

First of all, you need to know how much heat is needed to provide comfort to the inhabitants of the house during the cold season.

The following factors are usually taken into account:

- prevailing climatic conditions in the area where the building is located;

- material of which various structural elements of the building are made;

- the presence of insulation and materials used for this;

- type and performance of the ventilation system of the dwelling.

The result of the calculations, usually carried out by heat engineers, is the value characterizing the volume of coolant that must circulate through pipes and radiators. Measured in cubic meters of water per hour.

You should also calculate the pressure characteristics. That is, what is equal to the value of hydraulic resistance of all pipes and equipment installed in the engineering network. As a rule, for the average length of the system, this figure ranges from 2 to 4 meters of water column.

Another important factor influencing the choice of electrical equipment is the performance of the heating boiler. Here it is necessary to determine the dependence of the power of the equipment on the flow rate of water and the difference in its temperature in the output and supply nozzles.

In any case, it is advisable to give preference to the adjustable pumps. So you can manually or with the help of electronic devices to change the power and performance of the pump, depending on external conditions and load.

Useful options

Most pumps from different manufacturers are similar in design and technical parameters. Reliability is also usually great. Therefore, in order to somehow distinguish their products among competing models, well-known brands equip equipment with various additional devices that increase the comfort and ergonomics of their use.

Consider the most common:

- Dual pumping equipment.Such devices are used for heating of large residential buildings or commercial premises. They can pump a significant amount of fluid. In addition, in the event of a breakdown of one electric motor, the system will retain its functionality using the second pump in conjunction.

- Devices equipped with a timer and thermostat. Such units are installed in heating networks with indirect heating boilers. In this case, the pump capacity (number of revolutions) varies depending on the temperature of the incoming coolant. The hotter it is, the slower the circulation occurs. The timer allows you to turn off the pump at a time when it should not be used (for example, at night or during working hours).

- Equipment with frequency converter. Mounted only in complex heating systems, where the coolant flow in different elements of the network is not the same.

Such pumps can independently change the engine speed depending on the commands from the control controller. In case of failure of the electronics mode switching is carried out manually.

Self-installation procedure

Installation of a pump for a heating system is a responsible and complex process, however, if you feel confident in your abilities and have relevant knowledge, no one bothers to do the work yourself.

First you need to make sure that you have the following tools and materials:

- a set of open-end wrenches of various sizes (or two tools with variable distance between the horns);

- bypass - a special pipe with which the bypass pipe is installed, which allows to repair and replace the pump without draining the coolant and stopping the climate system;

- filters - protect expensive equipment from damage by solid particles, which are sometimes found in the coolant;

- Sgony- "American" - to connect plastic pipes with inlet and outlet nozzles of the pump;

- non-return valve - prevents backflow of fluid into the supply line.

The installation process itself consists of the following steps:

- It is necessary to purchase a pump whose capacity complies with the technical characteristics of the heating system being installed. The best choice for domestic heating systems will be three-speed centrifugal pumps, which make little noise during operation, but are able to pump large enough volumes of coolant.

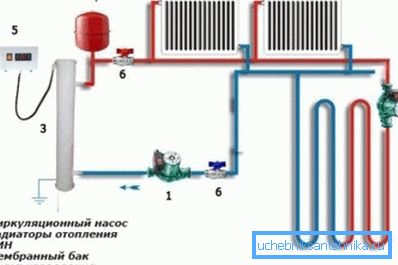

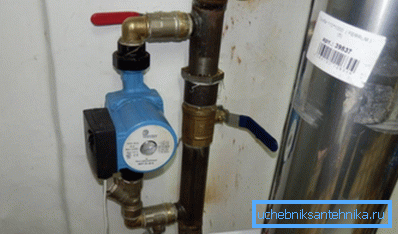

- The installation should be carried out on a segment of the pipeline that transports the already cooled coolant to the heating boiler (the so-called return flow). Here the water temperature is lower than immediately after leaving the boiler, so the pump will last you longer.

Note! In systems with forced circulation of coolant, the expansion tank - of the membrane type - is also connected to the return pipeline, and not to the central riser, as in gravity circuits.

- Before installation, do not forget to turn off the household heating boiler at home and shut off the shut-off valves at its inlet and outlet connections. After that installation of the pump is made. Connect it to the pipes with the help of sgonov- "American". Remember that the motor shaft must be oriented horizontally (with the exception of vertical pump types). Otherwise, the bearings will be subject to increased load, as a result of which the pump will quickly fail. To avoid leakage, instead of classic rubber gaskets, it is recommended to use paronite - heat-resistant gaskets made of rubber with the addition of asbestos.

- If a heating system with a closed circulation is used, a non-return valve should be installed in the supply pipe to avoid liquid backflow.

- The pump must be connected via appropriate stop valves. In this case, you can easily shut off the flow of fluid if necessary to repair or replace electrical equipment. In order not to interrupt the work of the climate network, it is recommended to install a bypass - a bypass section of the pipe (also with a tap) through which the fluid will flow during the time when the pump is removed.

Conclusion

After reviewing the above material, it will not be difficult for you to select and install a suitable pump for the heating system.

But the efficiency of the climate equipment depends on its other elements:

- boiler,

- radiators,

- pipes,

- expansion tank for heating system,

- sensors and so on.

You can learn more about this from the video posted in this article.