Radiator power. the principle of operation. factors

The power of a heating radiator is precisely the parameter that determines how efficiently a device will heat the surrounding air. Planning the reconstruction of the heating system, we need to master the method of calculating the performance of such products, since neither excess nor lack of power is unacceptable.

Battery heat dissipation

The principle of operation of the radiator

Before proceeding to the calculation of operating parameters, we need to understand how the heating battery works, and what value we need to calculate to evaluate its effectiveness.

The radiator (whether it is water or electric with an oil coolant) functions according to a rather simple principle:

- Inside the device there are reservoirs in which the heated coolant circulates.. The hot substance rises, the cooled - goes down, because the liquid is constantly in motion.

Note! In electric devices, heating occurs in the radiator itself, in water devices in the boiler or furnace, but in this case the differences will be insignificant.

- When moving, the coolant is in contact with the walls of the tanks, giving them some of their heat. In this case, the longer the contact time and the greater the temperature difference, the more heat the fluid gives off.

- Heated from the inside, the walls, in turn, transfer thermal energy to the environment, heating the air.

- To increase the efficiency of heat transfer, radiators are made in the form of fins., increasing the surface area in contact with air. Sometimes additional metal plates are fixed on the surface - they also serve to accelerate heat transfer.

Note! The presence of heat exchange ribs stimulates convection - the movement of hot air between the plates. Thus, two principles of heating are combined: radiator and convector.

Power radiators - steel, cast iron, aluminum, bimetallic, etc. - is determined by how much heat they can give to the environment per unit of time. In passports to heating batteries, this parameter is most often prescribed.

Selection of the optimal heat transfer device is very important:

- In systems of centralized heating, excess heat transfer leads to overheating of the room. As a result, we have to bear the cost of either additional airing or the installation of thermal valves - the microclimate itself is seriously deteriorating.

- If the performance of the installed devices is not enough, then they will be forced to work at the limit of their capabilities. On the one hand, this significantly reduces the life of the product, and on the other hand, it leads to a periodic “underflood”, when the temperature in the room decreases significantly, despite all the efforts of the hot water boiler.

- In addition, with a heavy load, the device can tritely fail. This is especially true for electric models, because the power of the oil radiator should be selected with a margin of about 20-25%.

Factors affecting heat transfer

If we analyze the information from manufacturers and experts, then we can see that, for example, the power of aluminum radiators for heating is significantly higher than that of cast-iron models of the old type.

This is due to differences in design and material:

- First, the larger the internal volume of the battery, the more coolant enters it, and the more energy it will give. Therefore, it is quite logical that a large device will heat more efficiently than a compact one (other things being equal, of course). The price will also differ, and not only due to the difference in the cost of the material used to produce the battery.

- Secondly, the performance depends on the temperature of the incoming coolant: the hotter the water, the more heat it will be able to extract.

- Thirdly, the better the material conducts heat, the higher its heat transfer will be. The least effective in terms of this indicator are products made of cast iron, and copper, aluminum and bimetallic models compete for leading positions.

Note! On average, the power of one section of the aluminum radiator is higher than that for bimetallic (aluminum + steel or aluminum + copper) structures. However, in practice, the nuances of production technology are also important, so this dependence is not literal.

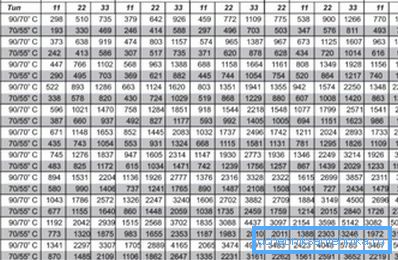

For comparison, below is a table of power radiators of various types. More detailed information on the thermal efficiency of some models of heating batteries can be found in the diagrams given in the article.

| Type of radiator | Heat output of one section, W | Heat carrier volume in one section, l |

| Aluminum, center distance 500 mm | 183 | 0.27 |

| Aluminum, center distance 350 mm | 139 | 0.19 |

| Bimetallic, center distance 500 mm | 204 | 0.2 |

| Bimetallic, center distance 350 mm | 136 | 0.18 |

| Cast iron, center distance 500 mm | 160 | 1.45 |

| Pig-iron, spacing of 300 mm | 110 | 1.1 |

It should be noted that the power of steel heating radiators, which have a panel structure, is indicated on the basis of the whole product, while for sectional structures, the instruction often contains two values: section heat output and the same parameter for the entire radiator.

Calculation of power consumption

Calculation methods

To select batteries for power, we first need to calculate how much heat the room consumes.

This can be done in several ways, so here we describe the most effective:

- First we need to calculate the volume of the room, multiplying its area by the height.

- Then we determine the basic need for heat by multiplying the volume by the standard coefficient of 41 watts.

Note! This value is valid for the European part of the Russian Federation. The southern and northern regions have their own standards, since the climate there is significantly different.

- The resulting value must be adjusted to compensate for heat loss. To do this, add 100 watts per window and about 200 watts to the front door.

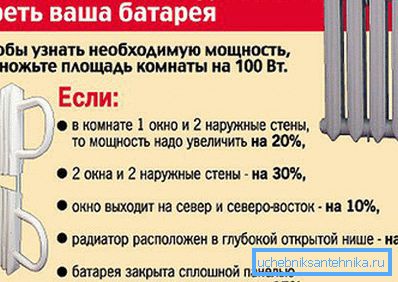

- There is another approach to compensating for heat losses: for example, with one window and one external wall, we increase heat consumption by 20%, two windows and two external walls - by 30%, while using screens for radiators - by another 25%.

Next, use the resulting figure to calculate the required number of heaters. To do this, divide it by the power of one section of the heating radiator and round off the result to a whole number.

The calculation of the number of sections on a simple example

So, let's try to figure out how, in practice, you can do the calculation yourself.

Baseline data are as follows:

- The area of the room is 16 m2.

- Ceiling height - 3.5 m.

- One window, one outer wall.

- It is planned to install sectional batteries with an inter-axial distance of 500 mm (the power of the aluminum radiator section is 139 W).

- Screens will not be installed.

The calculation method is as follows:

- Determine the volume: 16 x 3.5 = 56m3.

- Calculate the need for heat: 56 x 41 = 2296 watts.

- We introduce an amendment to the presence of windows and exterior walls: 2296 + 2296х0.2 = 2755.2 watts.

- We calculate the number of sections: 2755.2 / 139 = 19.8.

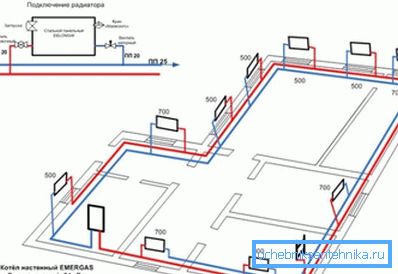

Accordingly, we need to install at least 20 sections of the aluminum radiator. Ideally, you need to purchase two panels of 10 ribs, placing them on opposite walls for more uniform heating - then the power of the heating system will be enough to maintain an optimal microclimate in this room.

Conclusion

Knowing the area of the room and calculating the radiator capacity per 1 m2, we will be able to pick up the heating devices necessary to ensure a comfortable temperature in the home. Of course, you can always install batteries with a margin of performance, adjusting their work manually or automatically, but still here you can’t do without calculations. You can learn more about the method of determining the heat transfer of batteries by viewing the video in this article.