Rehau pipes for heating: characteristics, varieties,

Plastic pipes for heating Rehau - is the leader in the modern market of metal-plastic and polymeric building materials for heat transfer systems, radiator wiring and underfloor heating. The company has a number of copyright developments, which have become a symbol of reliability and quality throughout the world, which determined the high popularity of its products. We will tell you what the special pipes for Rehau heating are, and consider their main types and installation rules.

Materials for heating systems Rehau

Composition of pipes and varieties

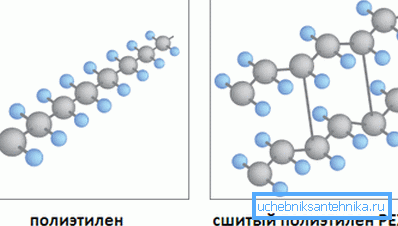

Rehau heating pipes are made of cross-linked polyethylene. However, some clarification is required here: there are many companies that manufacture products from this material, but not everyone can boast the same level of quality. What is the secret of the German company?

The fact is that cross-linked polyethylene can be obtained in various ways - by heating in the presence of peroxides, by treatment with silane with catalysts, by bombardment with electrons and X-rays, by nitrogen technology.

Accordingly, the materials are called PE-Xa, PE-Xb, PE-Xc and PE-Xd. Only peroxide technology (PE-Xa) gives the most high-quality cross-linking - up to 85% - it is the one that is most often used in the manufacture of materials from the German brand Rehau.

Note! In some models, to increase resistance to high pressure, PE-Xc can be used as a hard material as the inner layer.

It should also be remembered that oxygen tends to equalize its concentration and penetrates through various permeable membranes, which include polyethylene.

To counteract this effect, pipes of a special structure have been developed:

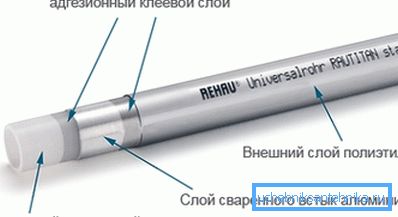

- Materials with a butt-welded aluminum layer. The structure of the product looks like this: PE-Xc - Al - PE-Xa. These are universal pipes of the Rautitanstabil series, which are suitable for drinking water supply systems and heating systems;

- Materials with a layer of ethylene vinyl alcohol. Here the structure is slightly different: PE-Xa - EVOH - PE-Xa. This arrangement is suitable for universal and pure heating pipes, used in the products of the Rautitanflex (universal) and Rautitanpink (purely heating) series products.

Note! It should be understood that the high price of the company's products is due to the use of expensive and high-quality materials, as well as high production technologies.

Characteristics and features

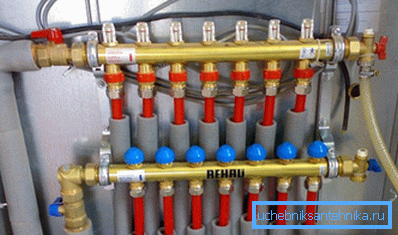

The technical characteristics of the products of this brand allow them to be used in various conditions, including radiator wiring, heat supply lines and underfloor heating:

- Structure of products: PE-Xc - Al - PE-Xa, PE-Xa - EVOH - PE-Xa;

- The maximum working temperature is 95 ° C, the normal working temperature is 70 ° C, the temperature of the permissible short-term peak is 110 ° C;

- The maximum working pressure is 10 atmospheres, short-term jumps up to 20 atm are possible;

- Guaranteed service life - at least 50 years.

The features of the products include their qualities such as the shape memory effect (the material tends to return to its original shape during deformation), the ability to bend pipes of small diameters without tools, noise-absorbing effect and thermal insulation activity.

Also, cross-linked polyethylene gives the minimum values of temperature expansion in comparison with other types of plastics, which is very important for heating pipelines.

Of course, for PE-X, the qualities characteristic of all plastics are relevant: low density and weight of the pipeline, chemical and corrosion inertness, high impact strength, low roughness of the inner surface, elasticity and ability to withstand hydraulic shocks.

Note! Separately, it should be said about the method of mounting connections, but we will do it in the next paragraph.

Installation

The installation of pipe joints and pipe fittings is extremely simple.

For you, we have compiled an instruction that will allow you to verify this:

- The end of the pipe is cut with a special tool at an angle of 90 degrees;

- We put the sliding sleeve on the pipe so that the chamfer is directed to the fitting to be attached;

- We insert the expander nozzle into the end of the pipe and flare the hole in two steps: after the first flaring, the pipe must be rotated about 30 degrees;

- Insert the fitting into the flared end until it stops (all 4 sealing ribs must be covered);

- Press the connection with the press. The sleeve should go into the pipe all the way into the restrictive barrier at the fitting.

Note! In order not to buy expensive tools, use the rental services provided by most large building stores.

Conclusion

Rehau products are of high quality and easy installation. Heating systems built using materials of this brand are distinguished by high reliability and long service life. The video at the end of the article will help you better understand the intricacies of editing.