Repair of heating radiators and oil heaters

Repair of radiators is a rather responsible process, but if you follow a few simple recommendations and accuracy, you will be able to perform work at the highest level. It is important to know all the main features of the process and not to try to fix the problems without the appropriate devices and consumables, the tools available here will not work, everything should be reliable.

In this review, we consider the most common problems and suggest the best ways to solve them.

How to organize a workflow

As in any other similar events, in this case it is necessary to carry out thorough preparation, which may include the following actions:

| Availability of the necessary tool | For example, when repairing aluminum radiators with your own hands, you need a special key to loosen the nipples, and for other options, twisting the couplings is required, and this requires an adjustable wrench. Therefore, understand in advance what devices may be needed, and prepare them so that during the work process you do not have to be distracted by the search for everything you need. |

| All the necessary components | Naturally, when you disassemble the structure when assembling it, it will be necessary to repack the thread with flax and special compositions, if you need to change the gaskets between the sections, then buy them in advance. It is also recommended to replace the fittings with new ones, especially if we are talking about products made of cast iron, especially since the price of the components is low |

| System preparation | If you followed the assembly recommendations and installed shut-off valves on all radiators, the repair will be very simple and fast, because you can block the flow of coolant separately on each radiator. If there are no taps, you will have to drain water from the entire system, which is much more difficult. |

Tip! If you are removing a radiator, you can install taps and a thermostatic regulator on it in parallel with the repair, this will allow you to optimize the operation of the system, and if necessary you can block the flow of coolant to the radiator in the future.

How the work is done

Here we consider not only ordinary batteries, but also touch upon such an issue as the repair of oil radiators, they also fail from time to time, and it is important to understand the nature of the malfunction in order to repair the structure.

Heating radiators

We will begin consideration with the work process, when the preparation has already been carried out, all the necessary materials and tools are at hand and coolant is drained.

As for the failure of steel products, due to the nature of their design, most often there are leaks at the connection points or the panel itself begins to leak, in this case it is necessary to determine if the damaged place can be welded, if this is not possible, then replacement will be the only option.

In more detail we consider the widespread sectional options and start with the classic cast-iron options, instructions for the work is as follows:

- Before repairing the radiator, it is necessary to determine the nature of the fault., if the intersectional connection is leaking, stock up with gaskets beforehand; if one of the elements has a hole, then it should either be replaced with an entire one, or simply removed from the system and assemble the structure into one section already.

- Disassembly begins by disconnecting from the pipeline., this is done with an adjustable or gas wrench, most often the joint is copiously coated with paint, so it is recommended to clean the nut to simplify the workflow.

- Please note that the product is very heavy., therefore, it is necessary for someone to hold the battery when twisting, otherwise it may fall on your feet, and with such a mass it is fraught with serious injuries and fractures.

- To make radiator repairs on your own more convenient, we advise you to prepare a slot or other surface in order to put a battery on it, a height of 50 cm is enough, the main thing is that the structure has access from all sides.

- Sections are interconnected by special nipples., which are located inside the structure and unscrewed with a special key - put it into the necessary section, after which the head should fall into the protrusions and lock in, for a long time the elements stick to the cast iron and break them can be very difficult, we advise you to use an extension cord to create great effort.

- After one nipple is torn off, it is necessary to tear off the second one and unscrew the construction alternately, so that there is no distortion, as this can damage the thread.

Note! Sometimes from prolonged use, the protrusions on the nipples are destroyed by corrosion and it is impossible to unscrew them with a special key, in this case, the damaged section can be removed with a sledgehammer or the element can be cut off by the grinder and the old nipple can be knocked out with a hammer.

- Next nipples are examined., if they are damaged, it is better to put new ones, if there is no gasket, then it can be made of paronite. The twisting takes place as follows: nipples are baited, gaskets are put on them, after which the second section is attached and the construction is tightened with a key.

Sometimes it is required urgent repair of the radiator with your own hands - when a leak occurs or the material is punched, the leak can be temporarily fixed with the help of cold welding, heat-resistant sealant or the so-called super tape.

With its help, some even make temporary repairs to the brass radiator in the car. But all options are not long-term, and the damaged element still needs to be changed.

Consider how to repair an aluminum radiator, its design is similar to that of cast iron, so when working, you also need a special key for nipples. We only note that the best way to repair a radiator of this type in the event of leakage is argon welding, but minor defects can also be sealed by yourself.

Oil heaters

This type of construction is also widely used in our homes, despite the reliability and simplicity, even in such devices there are problems, consider the main ones:

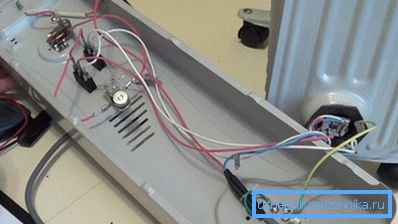

- Repairing an oil cooler with your own hands begins with the definition of the problem., for this, the device is placed on a comfortable surface and the protective cover is removed from it, since all the nodes are located just below it.

- If the contacts are broken, they can be wiped with an alcohol solution and tightened tightly for reliable fixation., If the problem is in the wiring, then it is necessary to ring it with the help of a tester, so it is easiest to find a break.

- If the control unit has failed, repair of the electric radiator consists in replacing this unit entirely, since it is not repairable.. If TEN failed, then the simplest option would be to buy another heater, since the element is rolled and does not provide for removal.

- With oil leaks, many also change equipment., but if you want, you can repair it, for this you need to drain the coolant, and clean up and damage the damage site, the process is not easy, so if you do not have the skills to perform such work, then it is better to refuse them.

Conclusion

Eliminate faults in the radiators can be done by any person, but the process is quite complicated, so it is important to observe accuracy and use only high-quality materials and reliable tools. The video in this article will show the workflow clearly.