Safety valve of the heating system - reliable protection of

The issue of security in the design of the heating system is given increased attention, especially in the case of independent heating. The main danger during the heating season comes from a sharp increase in pressure, pipes can simply not withstand this. Installing a simple safety device makes it easy to equalize the pressure in the system.

Features of the heating system

All elements of heating were originally designed for operation under certain conditions. In the process, there are often cases when the pressure in the pipes increases dramatically. And it is good if the pipes withstand such a test, but no one will guarantee that the next time there will be no leakage, so the safety valve for the heating system is simply irreplaceable.

As for the reasons for the sharp increase in pressure in the pipes, it can be distinguished:

- excessive water heating - when the temperature rises, the water expands, which causes additional stress on the pipes and valves;

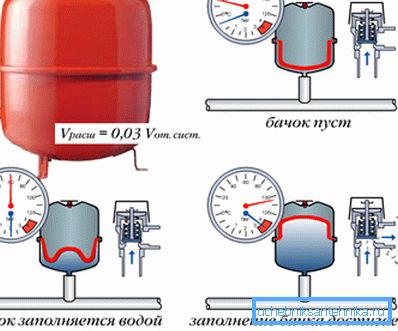

Note! In part, expansion tanks help to cope with such a problem. Excess water simply accumulates inside the tank.

- error in the selection of pipe diameters;

- if the heating is fed from the water supply network, and the pressure in it exceeds this figure in the heating circuit;

- even an ordinary thermal valve for heating (one that is installed in front of the radiator) can cause an increase in pressure in the supply pipe. This most often occurs during warm weather, when water flow into the radiator is reduced to a minimum;

- malfunctions in the circulation pump can also be considered one of the reasons.

How to ensure safety

When installing any heating system used such a thing as "security group". This term refers to a series of devices that allow you to monitor the operation of the system and promptly troubleshoot.

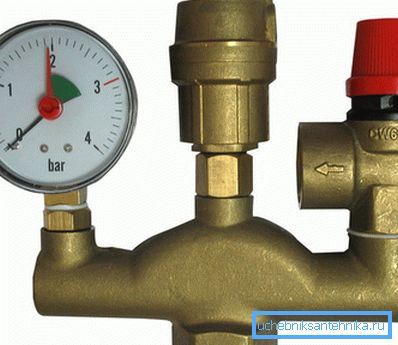

The security group usually includes:

- pressure gauge;

- air vent - allows you to remove air from the pipeline;

- in fact, a safety valve for heating is a device that allows you to dump excess pressure in a matter of seconds.

Classification

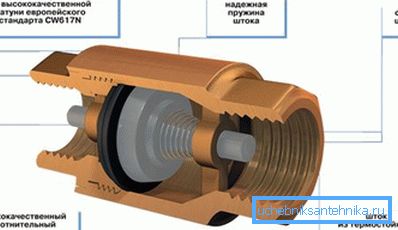

In the heating systems of apartments and private houses exclusively spring devices with continuously adjustable are used. By the ratio of efficiency, reliability and cost - this is an ideal option.

But in general, there are several more types of devices of this kind:

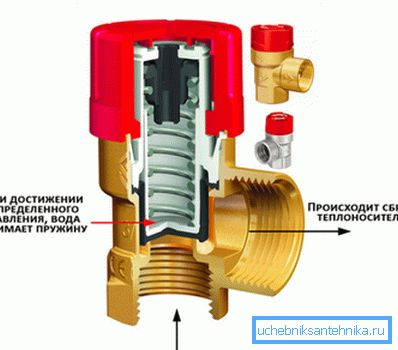

- spring - in such devices the spool rod is spring-loaded and at normal pressure the valve is closed. As soon as pressure begins to build up, the spring shrinks and the bore hole increases - the excess heat carrier is discharged into a separate container or into the return;

Note! The pressure required to open the valve must be at least 10-15% higher than the working figure in the pipes.

- lever-type devices it is distinguished by a high price and the possibility of flexible adjustment of the effort required for its opening. The load is on the lever, and it is fixed on it so that it can move. By adjusting the position of the load on the lever, you can increase / decrease the effort required to open it.

It is possible to cite the classification and the degree and method of recovery:

- if the lift does not exceed 0.05 of the saddle height, then such a device is considered low-lift;

- full-lift device provides movement of the shutter at a distance equal to the height of the saddle (or even greater than it).

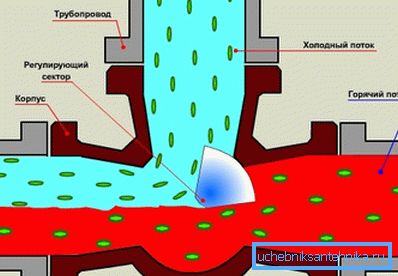

Regarding the method of adjustment, the check valve for heating can be:

- with a smooth adjustment - as an example, you can bring a spring type. The movement of the gate depends on the pressure in the pipe;

- with 2-step adjustment - a certain threshold pressure value is set, above which a passage opening automatically opens completely, and this happens almost instantly. Used in industry, where the loss of even a few seconds can lead to serious consequences.

Return and bypass devices

A check valve in the heating system allows the coolant to move only in one direction. The "highlight" of such a device is that the spring-loaded stem only allows water to flow in one direction. Thanks to the threaded connections to install it is not difficult.

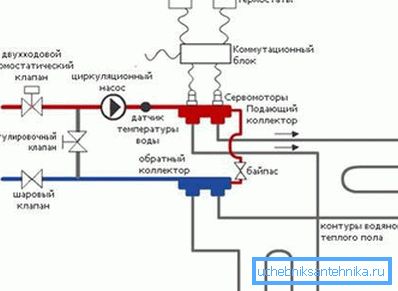

Sometimes, instead of an open-type fuse, a bypass valve is used for heating. Its main function is the same - equalization of pressure in the system, but if the open option simply drops excess coolant, then the by-pass analog will redirect water within the heating circuit.

If thermostats are installed in front of the radiators, then in the warm season there may be a situation when all of them quite strongly block the flow of water into the batteries. As a result, pressure rises in the supply pipe.

If a bypass valve is installed at the outlet of the boiler, then it will simply transfer part of the coolant from the supply pipe to the discharge pipe. So, if a heater valve is used, then additional protection of the heating system is necessary.

Three way valves

The main difference of this type of device is the design - 1 input and 2 outputs.

Thanks to this three-way device can be used to achieve:

- mixing the hot coolant with the cooled;

Note! This is necessary when using low-temperature heating (warm floor). The three-way valve allows you to organize the mixing of the coolant from the return into the supply pipe and eliminate the risk of supplying too hot water.

- A three-way valve for heating allows you to isolate one heating circuit from another (this may be necessary if different heat transfer media are used).

Inside the case there is either a damper or a ball, the rotation of which regulates the coolant current. A servo drive connected to the room thermostat can be used to control the damper.

A couple of words about the installation

Installation of all elements of the security group is done by hand. There should be no problems with the installation of a safety device, because threaded connections are used. And the main question is where to place all these elements.

The devices of the safety group should be placed in the area of the supply pipe at the boiler. Another subtlety is where to install the shut-off valves, which allow cutting the boiler instantly in the event of a malfunction.

Instructions for proper installation of a security group require the placement of a shut-off valve behind a group of these devices. In this case, even after cutting off the boiler, the safety valve will allow you to reset the excess coolant and save the boiler from damage.

The installation options for the shut-off valve in front of the security group and directly on the pipe section leading to it are considered incorrect. In this case, when the boiler is cut off, the security group will also be cut off, and the boiler may suffer.

Summarizing

Installing a safety valve allows you to increase the reliability of the heating system. Thanks to this simple and cheap device, pressure surges will no longer threaten the integrity of pipes, and heating will last for many years.

The video shows the principle of operation of the spring-type safety device.