Scheme of a solid fuel boiler: all the main elements of the

Constantly rising prices for basic fuels are forcing consumers to look for alternative ways. A fairly profitable solution is solid fuel boilers that work efficiently and are independent of the supply of centralized energy carriers.

Advantages of solid fuel heating systems

- The main unit of the autonomous system is indispensable where there are interruptions in gas supply, or there is none at all.

- Devices of this class are beneficial and the fact that there is no need to connect electricity to them. Only in some cases minimum power consumption is required.

- Today, the device of a solid fuel boiler allows to operate it with maximum heat transfer to the room.

- In most regions, wood and wood waste is the most affordable energy carrier, also at a cost.

- Attracts the smell of fresh wood and comfort from live fire. Fans of creating the aura of rural life will be able to fully enjoy the country rest.

- You do not have to run on instances for permission to install equipment. This is a big plus, because for mounting devices on gas or fuel oil, you need to get a lot of references.

Note! Firewood, coal, pellets or briquettes are not explosive. Therefore, the requirements for their storage are not so strict. It is enough to equip an extension or storage shed. In the extreme case, and the back room.

How is the unit

For the most part, the buyer is offered a round or rectangular device. Almost all of them - the descendants of the well-known "stoves", modified with time. Now improved solid fuel boilers facilitated their maintenance.

On average, putting firewood is necessary every 5–8 hours. The more the firebox, the more fuel it holds, and therefore the device can be fed less.

Firebox

The combustion chamber, or a fire chamber at the same time is also the heat exchanger.

It consists of the following elements.

- Capacity for fuel bookmarks.

- Combustion gas exhaust zone.

- Grate, on which firewood is located.

- Air supply hole.

- Portal for the accumulated ash.

Note! The main difference between the boiler and the stove is that the latter warms only the air around it. But the heating scheme with a solid fuel boiler is different in that the device is equipped with a water jacket around the furnace. Next, hot water is used for its intended purpose.

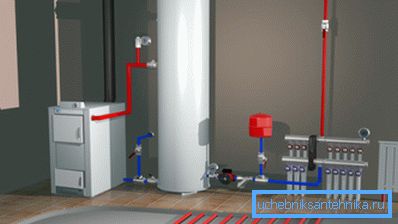

Water layer

The boiler has double walls, between which there is enough space for water.

That is where it is served for further heating.

- During the combustion of the fuel, the heat generated is heating up water. According to the laws of physics, a warmer fluid rises in the upper segment of the interlayer.

- Having reached the upper part, where the branch pipe is located, boiling water passes through it and is discharged for space heating through pipes to radiators, various coils or fed to the system of heated floors.

- The spent cooled water is returned through the lower pipe back into the jacket of the boiler for reheating.

Note! The overwhelming majority of boiler models work by gravity, that is, without the intervention of pumps. Only occasionally there are varieties, equipped with a circulation pump, accelerating the flow of water through the heating system.

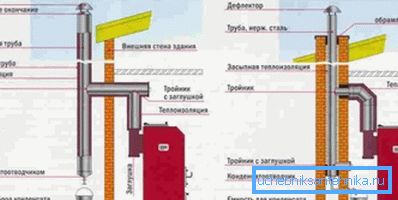

Venting system

Any solid fuel device requires an extremely careful attitude. Volatile combustion products - this is the same carbon monoxide. He many times led to the trouble of negligent users.

Instructions to all devices insists on mandatory ventilation and periodic cleaning of chimneys.

- The chimney is put out into the street, where gaseous waste goes.

- It is recommended to heat off the exhaust pipes.

- Cleaning inner surfaces from soot and soot is necessary to prevent clogging of pipes.

- It is convenient to install the model with forced ventilation. This will improve the air quality in the room.

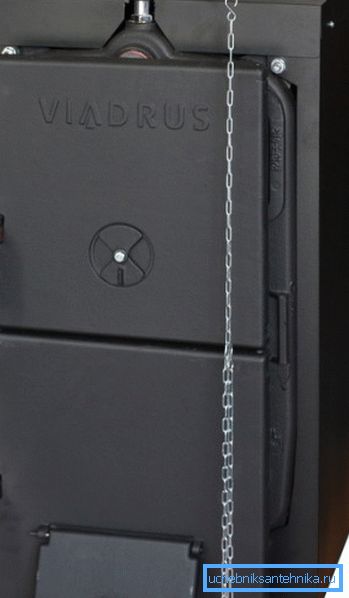

Temperature control

Modern boilers are equipped with elements that allow to regulate the flow of air into the furnace without your intervention.

Without oxygen, burning is impossible, and therefore, by increasing or decreasing its volume, it is possible to achieve the ideal efficiency of the unit.

- The valve and the special regulator are firmly connected to each other.

- When the temperature rises above the desired, the regulator walls expand, lowering the valve. The air flow at the same time becomes less.

- Lower temperatures provoke a reverse process.. A raised damper increases the access of oxygen to the furnace, stimulating more active combustion.

This heating scheme with a solid fuel boiler may seem primitive. However, as shown by long-term studies, it is the one that is most effective, and therefore is actively used in the manufacture of boilers.

Material classification

Since the devices are made of different materials, the question arises - which is more practical, more profitable and more convenient? In part, it depends on the purpose of the boiler, because today you can see both compact single-circuit devices and their powerful counterparts with many functions and additions.

Steel Boilers

They are distinguished by the lowest price and ease of maintenance. But they are capricious in terms of temperature, in the return pipeline should be higher than +60 ?. The disadvantage is eliminated by installing a valve that supports the desired mode in the return pipe, where hotter water is mixed in from the supply pipe.

Iron products

The metal which proved as reliable and durable material. Cast iron is ideal for lovers of capital and solid things. Many do not stop even a considerable cost, although it is fully justified.

For a small country house impressive and heavy equipment is impractical, but on a large area of the cottage iron device just right.

Fuel types

The term "hard" speaks for itself.

That's what boilers consume with pleasure, giving in return the benefits of civilization in the form of warmth and comfort.

- Hardwood.

- Wood and coal.

- Pellets (pellets from wood waste).

- Briquettes from chips and sawdust, cones, peat.

The last point is easy to organize with your own hands, if you can gather the gifts of the forest nearby and use a simple press.

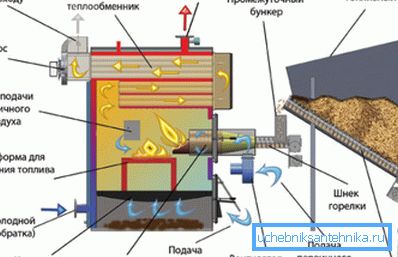

Separation by incineration

The most popular are the following types of devices.

- Traditional boilers.

- Analogs of long burning, where burning occurs from top to bottom (and not from bottom to top, as in normal). Convenient in that the frequency of laying fuel occurs less frequently (up to once per day).

- Pellet units, with automatic lining of the pellets in the chamber.

- Gas generating (pyrolysis) devices. The increased efficiency is due to the use of heat from the evolved gases, which is not in the types listed above.

Conclusion

Pick up the boiler for your house, its area, architecture and conditions. In most cases, this can be done intuitively or by consulting on-site with the seller.

It will help in the selection of videos with a detailed description of proven and proven models.