Sectional radiators: the device of the integral and

Apart from the fact that different metals are used to produce batteries, the design of the radiator itself may differ. In particular, it is possible to meet both modular (sectional) radiators, and solid ones. Each type has a number of advantages, and for informed choice it is better to consider in more detail in what situation bimetallic sectional heating radiators are suitable, and when complete models will fit.

Device one-piece and sectional radiator

The device of the heating battery depends on the material used:

- Classic cast iron radiators assume the presence of 1 or 2 channels for the circulation of the coolant. They are produced, as a rule, sectional, separate sections are connected to each other through a nipple with left and right threads on different sides;

Note! When you turn the nipple adjacent sections are tightly attracted to each other, but this is not enough to ensure the tightness of the joint. Therefore, sealing gaskets are necessarily used.

- Aluminum models are different in that even every single section can consist of several elements. Naturally, more joints do not benefit the durability;

- Steel sectional radiator is characterized by high strength and ability to withstand high pressure in the heating system. Also, the working temperature of the coolant can be raised to a temperature above 100? С. As for the types of construction, it can be sectional, panel and tubular (register), steel allows manufacturers to use almost the type of construction;

- Recently, bimetallic radiators have become popular, in which coolant circulates through steel pipes, but the fins are made of aluminum pipes. A combination of copper + aluminum can also occur.

The use of aluminum fins reduces weight and ensures quick heating of the radiator. In modern models, the design of the ribs is optimized so that the air moves in the direction from the bottom up. That is, in the lower part cold air is taken, and in the upper part it is already heated.

Of the design features, it is possible to note the presence of additional stiffeners between aluminum plates. Manufacturers write it in the dignity of their radiators, but in fact there is no particular benefit from this innovation, and the price rises slightly. Still, most batteries simply hang on the wall and do not experience significant mechanical stress during operation, so high rigidity is simply not necessary.

Features of operation and selection of radiator

Differences in design affect not only the appearance of the radiator. Its thermal capacity and reliability of operation depend on it (the more joints, the more weak points that can cause leaks in the future).

Comparison of monolithic and solid radiators

At the moment, it is often used sectional heating batteries. This can be explained by the fact that due to the change in the number of sections, it is simply more convenient for manufacturers to regulate the thermal power of the entire device.

As a rule, the work is structured as follows:

- standard sections are issued (thermal power of one reaches 170-200 W);

- then the battery is assembled from sections in the factory. It already takes into account the dimensions of the room.

Note! In principle, you can also remove unnecessary sections with your own hands, or vice versa, add missing ones But there is no guarantee that when assembling the battery, it will be possible to re-achieve the factory tightness of the joints between the sections, so it is better not to risk it.

There are a couple of significant drawbacks in the prefabricated structure:

- joints - potential sources of problems in the future;

- Such a battery is designed for a standard pressure in the heating system, that is, the use of coolant with a working temperature over 100? С is not recommended.

There are on sale and solid models of radiators. All the difference lies in the fact that the battery is made immediately full-size. That is, steel pipes act as a frame (coolant circulates along it), and aluminum fins are installed on it at the factory.

In this design, the disadvantage is that it is impossible to increase the thermal capacity of the device by adding additional sections. But in the advantages should be recorded the opportunity to increase the pressure in the heating system and the temperature of the coolant to 120-150 degrees. Such radiators are ideal for an autonomous heating system.

What to look for when choosing

Instructions for choosing is usually reduced to a simple calculation of the minimum required thermal power of the device, based on the area of the room. You can use the simplified method and proceed from the fact that at 10m2 you need at least 1 kW of thermal capacity of the battery (this value should be indicated in the documentation for the heater).

Note! The given dependence is valid only for ceilings with a height of 2.7 m, but if the ceilings are high, then the result obtained should be increased by about 15%. Also, when determining the required heat output, one should take into account the number of windows and doors in the room, the type of insulation, placement, etc.

In addition to heat transfer, attention should be paid to all sorts of useful things like floor brackets or a towel holder.

They will allow you to use the battery to solve minor household issues:

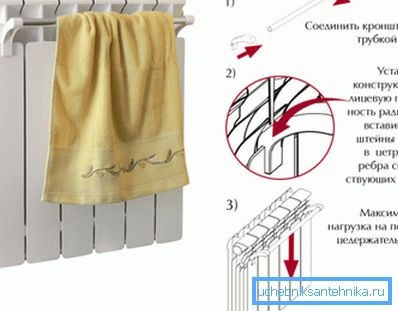

- towel holder for sectional radiators is a useful device that allows to dry towels, T-shirts and other small items around the battery. Externally, it looks like a metal tube (stainless steel), which is inserted into plastic holders. The holders are made in the form of clips with slots, they are simply put on the aluminum plate, to install such an addition to the battery, it must have at least 6 sections;

Note! If you try to dry the clothes on the radiator itself, there is a big risk of simply burning it, the fins heat up to a high temperature and brown stripes may remain on the fabric. Towel holder makes it impossible to contact fabric and metal radiator.

- floor bracket is good because it allows you to keep the wall safe and sound. Particularly relevant are such fastening systems in rooms with large windows, where the battery under the sill can not be accommodated.

Any floor bracket for sectional radiators has the same design - a plastic or metal leg with an adjustable height; there is a recess on its upper part for convenient placement of the radiator and a metal clip.

Differences may lie in the type of lock - can be used curved steel bar with a thread at the ends or a chain consisting of individual moving parts. When selecting the bracket, you need to take into account the length of the battery, if it is quite massive and exceeds 10 sections, then in addition to the brackets on the sides, you also need to add 1 in the middle of the radiator. If this is not done, the battery will sag and it is possible to flow through the joints at the bottom.

In conclusion

Sectional batteries have become so firmly established in our life that many people do not even suspect the existence of integral ones. Meanwhile, in individual situations, it is the whole radiators that may be preferable, because they can withstand more pressure in the system, and the coolant temperature can be raised by 40-50% compared to a conventional heating system.

The proposed information will allow you to make a choice. The video in this article shows the device of floor brackets for radiators.