Selection and laying of pipes for underfloor heating:

Modern analysts predict an increase in electricity tariffs in the near future. So, the price will increase not only for the use of electrical appliances, but also for space heating. In connection with such predictions, the search for the most cost-effective method of home heating is becoming increasingly important.

In addition to cheapness, I also want this system to not go beyond aesthetic appeal, while retaining the usual comfort in a home. One of the most common solutions that meet these requirements is the installation of “warm floors” in the house. The water-type design of polypropylene materials has proven to be the most cost-effective equipment for heating.

Features of a different type of systems

The benefits of installing a “warm floor” system can be appreciated by anyone who is at least a little familiar with the fundamentals of physics.

Today, depending on the type of coolant, there are two types of similar structures:

- Water;

- Electric.

Note! The principle of operation in the first and second cases is very similar. Under the surface of the floor hold pipes or specialized cables, which will heat it, and from the heated surface the warm air will rise to the ceiling.

Usually, this type of construction is installed in the kitchen or in the bathroom, and ceramic tiles are installed in them for the floor covering, due to its excellent thermal conductivity parameters. Of course, the warm floor is not difficult to equip in any other room, but depending on the type of flooring chosen, the efficiency of its work will also decrease.

In order to do the installation or the choice of pipes for such a system with your own hands, you need to have at least a minimum of knowledge about its technical characteristics.

Note! Manufacturers often mention all the advantages of the proposed product, keeping silent about its shortcomings, but in order to make the right choice, it is necessary to become familiar with the full picture of the parameters, especially since the price of such a system is quite high.

The main parameters of the water floor

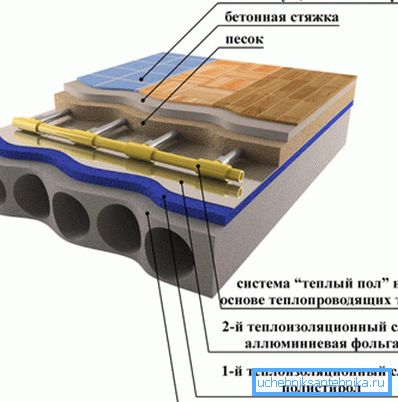

The pipe used to create “warm floors” is environmentally safe and economical, but in order to make its laying, additional equipment and preparatory construction works are needed that can significantly increase the cost (read also the article Steel rectangular pipes - technical information and regulatory requirements).

Laying pipes thickens the floor by about 10-15 cm. You will also spend some time on testing and starting. But in any case, get heating, which by the amount of electricity consumed will be much more economical.

Benefits

The advantages of such structures include:

- Uniform heating of the entire surface, even if, when choosing a pipe for a warm floor, you stop at the copper;

- Full masking devices;

- The ability to heat large areas at low cost;

- The work of the circuit is not associated with different types of radiation harmful to health;

- Installation costs are one-time in nature, due to the lack of need to maintain the system;

- No maintenance costs.

disadvantages

In addition to the advantages, systems of this kind have some disadvantages:

- The need to purchase a water pump;

- The complexity of the installation process when using polypropylene pipes;

- Problems with pressure reduction in the heating tower;

- Difficulties in detecting circuit leaks after final installation work.

Installation of a water floor

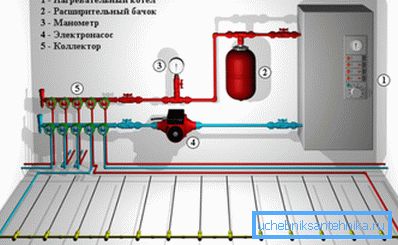

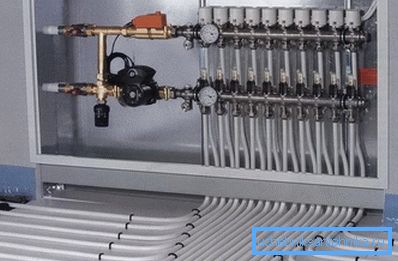

In this type of water heating system, the main heating element is a thermally insulated slab of concrete. Inside this plate there are built-in pipes of construction, through which the hot coolant circulates.

Brief instruction for installation of such systems consists of the following steps:

- An ideally flat cement-sand screed is created on the floor;

- On the screed along the wall is laid thermal insulation flooring with a film of aluminum, which will prevent heat loss;

- With the help of specialized fasteners, the pipe is laid on the thermo-insulating substrate according to how it is stipulated by the layout of the pipes of the heated floor;

- The created contour is filled with cement;

- The flooring is laid on the dried cement.

Note! In order for the created system to function correctly, it is necessary to purchase and install equipment that will control the flow of coolant into the pipe.

How to choose a pipe

To create such systems use the following types of pipes:

- Polybutene;

- Steel;

- Metal-plastic;

- Copper;

- Polypropylene.

Normative documentation prohibits the use of ferrous metal materials for the creation of such systems, since suture products cannot be walled in walls and floors.

High requirements for pipes are applied due to the fact that after laying the structure is poured with concrete and any damage will have to crack the cement. To create a "warm floor" are used specialized materials, and not those pipes that are used for the installation of hot and cold water.

Council The most suitable are materials with a diameter of 16 to 18 mm. Choosing such products, you can slightly increase the thickness of the floor, and for sufficient hydraulics do not need to purchase additional equipment.

Materials should have the following parameters:

- Oxygen diffusion obstruction;

- The coefficient of linear expansion of 0.025 Mm / mK or less;

- Thermal conductivity - 0.43 W / mK.

Note! To create a system in one room, it is necessary to purchase one whole piece, the operational period of which must be equal to the lifetime of the building itself.

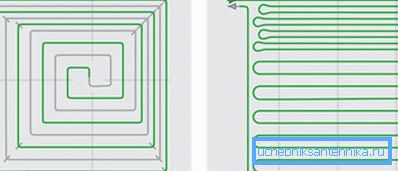

Laying pipes for this type of heating can be conducted by the following methods:

- Spiral or snail;

- Zigzag;

- Both methods.

When laying in different ways, the costs will be equal, but the efficiency of such systems will be different.

Note! Pipe consumption on a warm floor is directly dependent not only on the area of the room, but also on the surface slope.

Spiral styling

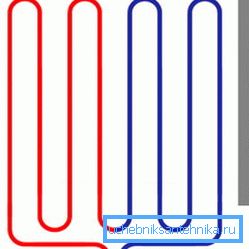

In this case, pipes with different types of streams alternate with each other - the hot pipe is adjacent to the colder section of the circuit.

This form of laying provides the most uniform distribution of heat. In apartments, it is usually used it.

Council The snail is not suitable for the room, the floor of which has a slope.

Zigzag laying

In this method of laying should be prepared for the fact that the floor will be hotter at the outer wall, and overcoming the distance, it will be cooled deep into the room. In order to ensure uniformity of heating, it will be necessary to purchase additional pumps, which create a greater rate of movement of the coolant.

Pipe spacing

The distance between the pipes of the floor heating, also referred to as the pitch of the pipes of the floor heating is calculated depending on the purpose of the room. The smaller the pipe pitch when laying a warm floor, the more the surface will warm up.

In this case, heat is distributed over radii; therefore, for the most efficient heating, care should be taken that these radii do not overlap.

Council Laying should be done on the square markings that are present on the insulator.

Some features of the design

In fact, the process of designing such heating structures is not so simple.

In order to correctly calculate the pipe on the warm floor, you must consider a number of factors, such as:

- Desired temperature;

- Purpose of the room;

- The parameters of the materials used, etc.

Note! The design of such systems is made today with the help of specialized computer programs. Using this software allows you to determine not only the amount of materials and equipment, but also what will be the maximum pipe length for a heated floor.

Requirements for installation

Work on the installation of a “warm floor” is possible only after the necessary preparatory construction work has been completed. The thickness of the created floor will be about 10-13 cm.

Therefore, it is necessary to comply with the requirement in the presence of at least 70 mm under this construction. Otherwise, the thickness of the heated floor should be increased.

If the installation of the heating circuit is carried out in the bathroom, the design will force to raise the floor of this room to a higher level. If you do not take into account this fact, then in the event of an emergency, water from this room will drain into the rooms.

If the floor of the room is adjacent to the ground, then it should be ensured that it is well-insulated. If bitumen was used for waterproofing, then a substrate made of polyethylene or cardboard should be arranged under the thermal insulator.

The cement-sand mixture should have a perfectly flat surface. The allowable amount of irregularities is only 1 cm.

In places where height differences are present, the pipe may acquire a curved shape, which contributes to the formation of an airlock in the system, which prevents circulation of the coolant.

Finally

Having made a choice in favor of a water-type floor heating, you guarantee your home warmth and comfort. In addition, an environmentally friendly design will not have a harmful effect on your health and the health of your household (see also the article Water and Gas Pipe and its features).

And the video in this article will reveal to you even more secrets of installation of this type of heating circuit and the subtleties of the choice of pipes.