Self-made heating boilers: how to choose the unit design and

In a country house is often an urgent problem of its heating in the cold season. Conventional coal-fired or wood-burning stoves are not very efficient: their fuel costs are irrational, it takes a lot of time to remove soot and ash, and there is a temperature drop in the rooms. An excellent solution to the problem voiced will be the heating boiler.

Such units are more modern and efficient than furnaces. With sufficient power, the device will be able to heat not only a residential building, but also an industrial, commercial building. If desired, such a unit can be made by hand.

How does the boiler for heating

All heating boilers are arranged according to the same principle - burning fuel transfers heat energy to the heat exchanger. That warms the heat carrier - water, oil, antifreeze (see also the article Calculation of heating radiators: the need for thermal energy and the number of sections).

For the effectiveness of the unit are two indicators.

- Fuel burn level. When an insufficient supply of oxygen with combustion waste removes liquid fuel vapors or pyrolysis gas, and they can give up a lot of energy during combustion, then the homemade heating boiler needs to be modified.

- Heat exchanger device. The more the contact area of the combustion chamber and the water tank, the more heat energy is transferred from the combustible heat carrier for a certain time.

Note! On this basis, the temperature of the combustion waste should be as low as possible. With the fall of this indicator at the boiler efficiency increases. In addition, the lower the temperature in the chimney, the more durable it will be, and the operation of the unit is safer.

Choice of device design

When you make drawings of home-made heating boilers, the availability of materials and a particular type of fuel in your area will affect their appearance and operation.

- Availability of materials. Heat-resistant steel is more suitable for heating units than ordinary stainless steel. But the latter is used more often. The point is that the material is easily accessible, and its price is lower.

- Processing capability. Cast iron pot can not do at home.

Therefore, when homemade solid fuel boilers are made, the most common material for them is sheet metal.

- The thickness of the steel should be 4/5 mm. You can handle it with a grinder, gas or electric welding.

- The unit device is dependent on the type of fuel selected.

- The design is influenced by the method of circulation of water in the circuit.

- The instruction notes that in order for the water to be heated to circulate by natural convection, a considerable tank height and a large cross-section of the nozzles, as well as heating circuits, are necessary. The smaller their diameter, the greater the hydraulic resistance and the lower the rate of circulation.

- If you put the pump, it will increase the speed of the flow of water, thereby allowing to make the cross section of pipes and the height of the tank less.

When home-made heating boilers for the house are mounted, it is worth remembering a few recommendations.

- It is better to make the heating circuits and the nozzles of the unit from pipes with a cross section of at least 32 mm.

- Since when the pump is turned off, the flow rate of the coolant decreases, its temperature increases. Therefore, the heating circuit should be made of galvanized pipes. Analogues of plastic (it has low resistance to high temperatures), even reinforced, it is better not to use.

Types of units

The most common wood boilers.

Wood aggregates

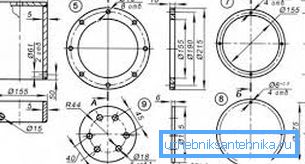

- The simplest homemade wood heating boiler has the appearance of two cylinders, the smaller of which is located inside the larger one.

- The inner structure is a firebox, and the outer one is a water tank.

- To minimize welding work, it is possible to use a thick-walled large-section pipe as the body of the unit.

- Homemade heating boiler on the wood can have different sizes and shapes, based on the availability of these or other materials. So, you can mount a welded rectangular furnace inside a cylindrical water tank. As an option - to place in the furnace a coil or heat exchanger from a number of pipes arranged longitudinally or transversely.

- Wood boilers can be stoked on any type of solid fuel. For them, suitable coal, pellets, regular firewood, dry peat briquettes, etc.

The main disadvantage of such devices is their low efficiency.

Pyrolysis analogues

- In such boilers, at temperatures of 200/800 ° C and a limited supply of oxygen, wood emits heat during combustion and is converted into pyrolysis gas and wood coke. Further, air is mixed into the heated gas, which causes the substance to ignite with the release of a large amount of thermal energy.

- The result of this is the high efficiency of devices reaching 92%. On one portion of the fuel unit can operate 10/12 hours. The usual homemade solid fuel boiler has an indicator of 4 hours.

- Fuel in the unit burns through with a minimum amount of waste. The burning of the gas can be regulated by means of automation.

Note! When the gaseous and solid fractions of fuel are burned separately, the requirements for moisture content of firewood increase. With a value of more than 30% gas with a large volume of water vapor burns no matter.

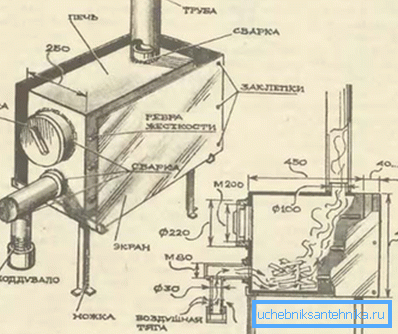

Waste oil units

Interesting boilers to work out. They evaporate the oil before it burns. When the unit reaches operating temperatures, the dripping into the heated pallet is instantly converted to gas, which, when burned, heats the heat exchanger.

As fuel in such units, you can use diesel.

Electrical equipment

Homemade electric boiler for heating is very simple in design. Inside the pipe of large cross section have heater. The return pipe is welded to the housing from below, the feed is mounted on top.

It should be noted that electric boilers with a capacity of more than 7 kW are not allowed to be connected to the mains at 220 volts.

The voltage at 380 is not everywhere.

- More complicated homemade induction heating boiler.

- Its simplest design consists of a thick-walled plastic pipe. Enameled wire is wrapped around it in 100 turns.

- It is connected to a welding inverter having a current (output) of 15 A.

- Inside the case there are elements heated with vortex current - trimming steel bar or thick wire.

- The return pipe is connected to the housing from below, and the supply from above.

- The circuit is filled with coolant, and the unit is connected to the power supply.

- A pump is not required for such a device. Circulation provides convection of heated water.

Conclusion

Heating boilers can be done independently. Such devices are much more efficient than furnaces and can increase the performance of the heating system (see also the article Self-Flowing Heating System: Features of the Device).

The video in the article still contains a lot of interesting things.