Single-circuit gas heating boilers: economical heating with

The most common, environmentally friendly and economical equipment for heating private homes and apartments are rightly considered to be double-circuit and single-circuit gas floor heating boilers. And, although the latter can not heat water for hot water, their price is somewhat lower, as well as gas consumption, which makes this choice more than justified.

The principle of operation and features

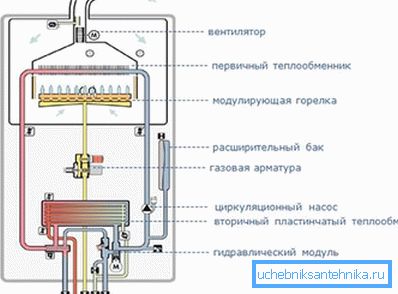

As you already understood, modern industry produces two main types of gas climatic equipment:

- Dual-circuit heaters, which in addition to increasing the temperature of the coolant entering the heating system, heat water used for domestic purposes. For this purpose, there are two coils in the combustion chamber, and in some cases, a storage tank, which contains a supply of already heated water.

- Single-circuit gas heating boilers - perform only one function - maintaining a comfortable temperature in the room. Their advantages consist in a small (compared to the previous version) cost, reduced coolant flow rate, simplicity of design, ease of installation and maintenance.

Single-boiler gas boilers - heating, but not hot water - have been known for a long time. Back in the last century, engineers found a way to convert the energy of a burning gas into heat that heats a home.

However, compared to the acetylene torch used previously, modern devices have many advantages, which were the reason for their wide distribution:

- all products of combustion harmful to humans are brought out through a special coaxial channel;

- gas single-circuit heating boilers effectively distribute heat to all rooms of the house (by means of radiators, pipelines and heat carrier) and do not require carrying a gas pipeline to each room;

- all heaters contain control and control equipment, using which you can set the required mode of operation with your own hands that is maintained throughout the heating season;

- floor and wall gas single-circuit heating boilers have an improved design of the combustion chamber, due to which very high efficiency is achieved (according to assurances of some manufacturers - more than 100%).

Note! Despite all the advantages, a single-circuit gas boiler for heating continues to be a high-risk equipment, since a violation of the procedure for handling gas can cause harm to human health and property. Therefore, there is an instruction containing safety regulations that should be strictly followed.

Benefits of using

Currently, in addition to natural gas, there are several other energy sources that can be used to heat a residential house or commercial premises:

- firewood;

- coal;

- electricity;

- diesel fuel.

An analysis of the prices of the above fuels convincingly proves that the use of gas is the most profitable right now.

Replace the gas single-circuit heating boiler and, at the same time be more economical, can alternative innovative equipment that uses for heating the energy of ultraviolet rays of the sun, wind and heat accumulated by the soil.

These are the following devices:

- solar collectors;

- wind power plants;

- heat pumps.

But the initial cost of installing such equipment is quite high, and the payback period is from 15 to 30 years, which is not available to every consumer. Therefore, the main natural gas is almost the only alternative.

Note! All the amenities provided by single-circuit gas heating boiler, are available only if the main gas pipeline is connected to the apartment or house.

Species

Installation location

Depending on the power, size and design features, there are several types of gas heaters:

- Single-circuit gas wall heating boilers. As a rule, these are household appliances of small capacity and size that can be used to heat a city apartment, a country house, or a small cottage. Their main advantage is compactness. For installation, you do not need to allocate a separate room, just hang it on the wall of the kitchen or in the pantry.

- Single-circuit floor gas heating boilers. These are massive devices of high power, capable of providing heat to residential buildings with an area of more than 300 square meters, as well as industrial and commercial premises.

The equipment is massive, because the brackets can not withstand their weight. They are usually installed on the floor in boiler rooms, which are a room in a house or a separate building. The latter option is more preferable, as it allows to protect people living in the house from gas leaks.

Used energy carrier

Gas wall single-circuit heating boilers run on natural gas, which is supplied to the consumer through the main pipeline. However, many household models come with parts that allow you to easily retool the burner to use liquefied gas, which can be purchased in cylinders.

Powerful floor heating devices cannot function on bottled fuel, since an extra large reservoir is required for their operation, which makes such a decision uneconomical.

Heat exchanger material

This term refers to a gas unit assembly, by which heat from the combustion of fuel is transferred to the coolant. The latter is piped into the radiators, which heat the air.

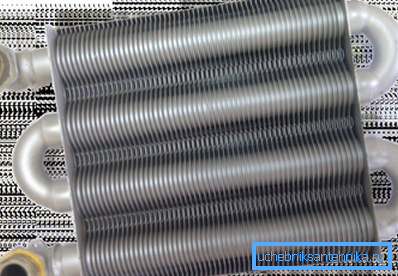

Modern manufacturers produce heaters, the heat exchanger of which is made of such materials:

- Steel. The cheapest but least durable models. Their service life does not exceed 10 years, after which it may require replacement. Steel heat exchangers are not installed in high capacity boilers due to their low efficiency.

Structurally, such a heat exchanger consists of a cylinder, where combustion takes place, around which pipes with circulating water are arranged in a spiral. The fuel in such boilers is a gas-air mixture, because the heating equipment and requires a two-channel coaxial pipe, carrying out fresh air intake from the street.

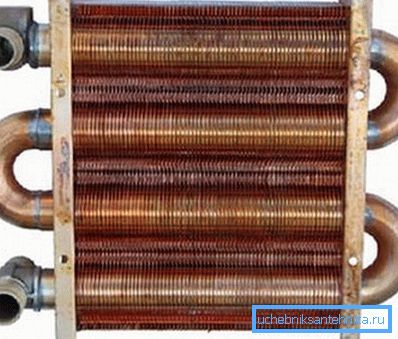

- Cast iron. Their wide distribution is hampered by large weight and sensitivity to significant temperature fluctuations (the cast iron in this case cracks). However, the advantages include high thermal conductivity, inertia and durability.

Most often, cast iron heat exchangers are installed in powerful floor boilers, where weight does not play a significant role.

- Copper. More than 8 times more efficient than both cast iron and steel. However, copper cannot withstand high temperatures, because heat exchangers of this design are installed only in low-power heating systems designed for individual use (in apartments and small cottages).

The design of the combustion chamber

Single-circuit boilers used for domestic needs may have an open and closed combustion chamber.

The first, that is, boilers equipped with an atmospheric burner, are used to maintain the flame of the air in the room. In addition, they need a chimney to remove hazardous products to humans.

To ensure the safety of the inhabitants of the house when using the boiler with an open combustion chamber, you must comply with the following requirements:

- the heater can be installed only in a separate room (boiler room), whose area exceeds 4 square meters (sometimes more - it all depends on the power and size of the unit used);

- to ensure ventilation in the boiler room, a door with a minimum width of 80 cm and a window must be equipped;

- It is necessary to follow certain rules when designing a chimney - it should be wider than the boiler outlet, stand strictly vertically (as a last resort, have no more than 3 turns), and be made of stainless steel with insulation that prevents the formation of condensate.

Note! If you violate the rules for constructing a chimney, natural air draft that removes combustion products will not appear in it. Because of this, an explosive gas that is dangerous to humans can accumulate in a room.

Unlike the type described above, the boiler with a closed combustion chamber is equipped with a turbine that draws fresh air in and removes the combustion products. For the operation of such heating equipment, it is sufficient to install a coaxial channel of small diameter, facing the street.

The outlet pipe consists of two parts: on the inside - smoke is removed, on the outside - air is drawn in. The air mixture entering the burner is partially heated, which increases the efficiency of the equipment.

The disadvantage of the turbine boiler is the need to connect it to the electrical network, because electricity is needed to power the air fan motor.

Ignition method

Currently, the most common model of gas boilers, equipped with electronic ignition devices. Special equipment analyzes the ambient temperature and ignites or extinguishes the flame, depending on external conditions.

Thanks to electronic ignition, significant gas savings are achieved while maintaining comfortable conditions in the room. And the equipment works without requiring human intervention.

Nevertheless, such models of boilers have several drawbacks:

- when the power supply is cut off, the unit will cease to function, which in case of a long-term accident can lead to freezing of the coolant and disruption of the integrity of pipelines and radiators;

- the installation of such boilers is impossible at summer houses, where, for the purpose of fire safety, the power supply at the end of the summer season stops completely.

The solution is to buy a piezo-ignition boiler. In this case, to initiate the combustion process, you must press a special button. After that, the ignition of the gas occurs with the help of a constantly working igniter.

The disadvantage of this solution is the increased consumption of natural gas, which is consumed for the ignition of the igniter.

Use of heat

Manufacturers of gas boilers are constantly working to improve the efficiency of their use and increase efficiency.

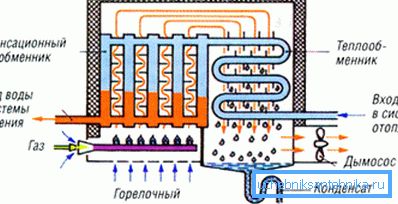

Thanks to their efforts, there are now two main types of boilers, one of which is more cost-effective:

- Convection heating units. The efficiency of the boiler is influenced by the moisture that forms in the heat exchanger. To remove it in this type of boiler, a high temperature of the combustion chamber is used. However, in this case part of the energy obtained from gas combustion is spent on evaporation, and not on heating the coolant.

- Condensing boiler. In this case, the temperature of the heat exchanger is somewhat lower, which leads not to evaporation, but to condensation of the liquid. Thanks to this design feature, an increase in the power of the equipment is achieved.

Conclusion

Single-circuit heating boilers - a great solution to ensure a comfortable microclimate in the house or apartment. However, if your home is not equipped with a centralized engineering network for supplying hot water, you will need to take care of this additionally (see also the article Gas double-flow boilers for heating is an excellent solution for heating a country house).

For more information about the climate systems used in private homes and apartments, you can learn from the video offered to your attention.