Solid fuel boiler dacon: how to choose an inexpensive and

Specialized retailers selling climate equipment to choose are presented to the buyer a huge number of different models of heating devices, which are different from each other in price, power, ease of use and many other parameters. But experts in this field have consistently chosen the Dakon solid fuel boiler, which is a model of uncompromising quality and economy.

The history of the brand

Dakon was registered in the Czech Republic in 1949. The company was founded not from scratch, but was formed as a result of the merger of several manufacturing companies engaged in the production of various climatic equipment. The concern began to specialize in the manufacture of heating boilers only since 1965.

However, after 5 years, thanks to the skillful leadership, Dakon takes a leading position in the domestic market.

The range of boilers manufactured by the company includes the following models:

- solid fuel boilers Dakon (classic and pyrolysis);

- oil-fired heaters;

- gas climatic equipment.

At that time, production volumes did not exceed 30 thousand units per year, and power - 30 kW, that is, heaters could be used exclusively for heating small and medium-sized residential buildings.

The next 20 years were marked by explosive growth for the company. By 1990, the number of produced boilers exceeded half a million, the range included models used for heating industrial complexes and commercial buildings.

Note! The population of a small area of the country - the Czech Republic - is concentrated mainly in the cities. Therefore, the domestic market could not absorb such a quantity of products, in connection with which a large part of it was originally intended for sale abroad.

In 1994, the country switched to a market economy. It was then that the company was sold into private hands, but this did not affect either the quality of the boilers produced or the volumes.

This is evidenced by the company's continued ongoing success in the Czech and international market:

- in 1995, the company acquired the assets of the Italian manufacturer of climatic equipment, Unical;

- in 1996, the company's production centers produced the first Dacon solid fuel boilers, in which the pyrolysis scheme of fuel combustion was implemented;

- in 1998, the company started the production of wood-fired heaters with a cast-iron firebox, with increased strength and long service life;

- in 2000, the company launched condensing boilers on the market, characterized by increased efficiency;

- In 2003, Dacon became part of the international concern Baderus, which is part of the world famous German holding Bosch.

Nevertheless, given the worldwide fame of the brand Dakon, the leadership of the German corporation, it was decided to preserve the brand. And now the company's production centers produce solid fuel boilers Dacon, which continue to delight consumers around the world.

Types of solid fuel boilers Czech production

DOR Series

A feature of these boilers is the possibility of using wood as a fuel with a moisture content of 20 to 35%.

In addition, the special design of the burner makes this heating unit versatile, because in addition to classic wood, the device can function:

- on brown and black coal;

- on coking coal;

- on coal briquettes.

For such a decision, one has to pay with a rather low efficiency and low power: the equipment can produce no more than 45 kW of thermal energy.

In addition, the line of coppers Dakon DOR has the following features:

- The device can be part of a closed heating network as with forced circulation of fluid (water pumps are used) and the gravitational system (the coolant flow is organized due to the difference of its temperature and density).

- The furnace is constructed of high-strength refractory steel and protected by a layer of special baked clay. (chamotte) capable of withstanding exposure to an open flame with a high temperature.

- The special design of the grate, which is turned with a lever, allows you to clean the combustion chamber with your own hands without opening the door.

- The power of a solid fuel boiler is increased or decreased using a thermostat that regulates the amount of air supplied.

Note! The temperature valve operates completely without electricity, so the boiler is fully autonomous climate equipment and continues to heat the house in case of an accident in the power grid.

- It can heat the coolant circulating in the system with minimal pressure (2 atmospheres). The minimum working temperature of the water is 65 degrees Celsius, the maximum is 95. The instructions for using the boiler also provide less heating of the liquid, but in this case condensate will appear on the heat exchanger, reducing the service life of the boiler.

- For ease of use, the firewood loading channel has the shape of a narrowing funnel. The door is located in the upper (horizontal) part of the boiler.

- In order to improve the appearance of the climate equipment, the firebox door is lined with a decorative panel, which is also a heat insulator.

DOR F Series

This range of boilers Dakon is not much different from the modification of the equipment described in the previous section. Some improvements nevertheless occurred, and they did the good by improving the ergonomics of operating the units.

The complete list of changes is as follows:

- The firebox door no longer has a lining. Although this somewhat worsened the appearance of the boiler, it greatly increased the usability of the equipment.

- The exterior has been slightly modified to fit the new trends in industrial design.

- The system for fixing the heat insulating layer and the ash pan door was redone. Now the accidental opening of the valve during the operation of the boiler is absolutely impossible, thereby increasing the safety of the person servicing the unit.

- Solid fuel boilers Dacon DOR F are equipped with nozzles with a section of 1.5 inches, so that you can dock the pipes that transmit the coolant, without the use of additional accessories.

- Increased minimum boiler power. Now this value is 13.5 kW (with a maximum of 45 kW).

Engineers of the Czech company have worked on the mass. Now the weight of the most powerful boiler is 320 kg. The maximum operating time depends on the fuel used and is about 12 hours.

FB D series

This is a fundamentally different line of heating equipment.

The main differences are as follows:

- The housing of the unit and the heat exchanger itself are not cast from steel, but from cast iron.

- The boiler can operate not only on solid fuels, but also on gas or diesel fuel. However, in order to use an alternative energy carrier, it is necessary to modernize the burner with the help of the equipment supplied.

Now we will focus on the main consumer properties of the equipment:

- minimum power of 17 kW, maximum 42 kW (this value varies depending on the currently used energy source);

- the air enters not only through the grates from the ashpit, but also through the grate in the combustion chamber damper (here an adapter is mounted through which the diesel feed system is connected);

- the door for loading solid energy is not located on top, but on the side of the device;

- flame power control is carried out with the help of a damper that increases or decreases the amount of air supplied to the combustion chamber (the system is as simple as possible, but non-volatile and reliable);

- the boiler can operate in heating networks with pressure reaching not 2 (as in the previous lines), but 4 atmospheres;

- the maximum temperature to which the coolant can be heated is 90 degrees Celsius;

Note! The boiler at the factory is not equipped with insulation and decorative cladding. They come separately and are fixed on the equipment after its installation in the boiler room.

It should also be noted that, despite the use of cast iron, the mass of the boiler remains within reasonable limits. The weight of the older model is only 30 kg more, which is what Dacon DOR F is 350 kg.

FB2 Series

It is also a line of cast iron boilers capable of operating on two types of fuel. (See also the article Heating system with natural circulation: features.)

However, there are differences:

- The maximum moisture content of the firewood used should not exceed 20% (less dried wood can be placed in the chamber, however, you cannot achieve the capacity stated in the accompanying documentation);

- the possibility of using energy carriers such as lignite and pallets is completely excluded.

Firewood and coke are loaded from the front end. Air enters through a blower, the damper of which is regulated by a mechanical thermostat. The boiler operates without electricity.

A huge disadvantage of this type of equipment is the minimum operating time on a single load of firewood. It is 2-5 hours, which forces him to constantly monitor his work, even at night.

As in the previous line, the door of the combustion chamber is equipped with a flange for mounting a burner that burns gas or diesel fuel.

As for the parameters of the coolant, they completely repeat those of the FB D boilers, and there is no need to dwell on them separately.

KP PYRO series

As the name implies, these heating devices operate on the principle of pyrolysis. And the fuel for them can serve exclusively firewood.

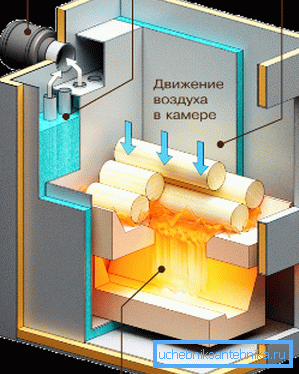

The principle of operation of pyrolysis boilers is as follows:

- In the upper firebox, wood is burned under conditions of lack of oxygen. Due to this, the so-called pyrolysis gas is formed, and firewood is processed into the smallest ash, which requires removal no more than once in 5 days.

- The resulting combustible gas enters the lower chamber, where it is afterburning.

Thanks to this scheme, the maximum efficiency for solid fuel boilers is reached - up to 85 percent. In addition, a special electronic system allows you to very accurately adjust the power in a wide range of values. You can create more comfortable conditions by adjusting the temperature in the rooms depending on the external conditions, as well as significantly save fuel, which reduces the cost of buying it.

Note! For such consumer properties also need to pay something. In particular, it is allowed to burn wood in the pyrolysis boiler whose moisture content does not exceed 20%.

Consider the remaining characteristics of KP PYRO:

- They can be installed only in heating systems with forced circulation of coolant.

- Fuel is loaded from the butt. Firewood is used extremely economically. For the smallest boiler, this figure is 5.7 kg per hour, for the most powerful - 10 kg per hour (it produces 38 kW of thermal energy).

- The boiler must be connected to the outlet. A fan that removes combustion products and a pump that circulates air consumes about 55 watts. With their help, adjustment of equipment operation parameters is carried out.

- For precise control of the boiler, a thermostat with external temperature sensors or an electronic control system can be additionally supplied to it, which allows you to program certain parameters taking into account the air temperature and time of day.

- The maximum temperature of the coolant is 95 degrees Celsius, the pressure is 2 atmospheres.

- One load of fuel allows you to maintain burning for 10 hours.

KPPYROF

This is a modernized series of pyrolysis boilers, in which the deficiencies identified during operation were eliminated.

The list of changes is as follows:

- The fuel chamber is protected by ceramic plates. Due to this, the work resource has increased to 4200 hours (this is about four years of standard operation), but the efficiency has dropped slightly (to 78%).

- The power of the fan that removes products of combustion has decreased. Now its minimum capacity is one third of the nominal.

- The flap of the combustion chamber became larger, which could not but affect the ergonomics of the use of equipment, in particular, the laying of the fuel.

- Modernized electronic control unit device. The situation when the reverse flow of water came from too high or very low temperature is excluded. Now the water pump under the control of the microprocessor will work until the coolant reaches the specified parameters.

- The minimum power of a solid fuel pyrolysis boiler Dakon KPPYROF is 21 kW.

Advantages of solid fuel boilers from the Czech Republic

The history of the brand Dakon has more than a dozen years. And during this time, the company's specialists have learned how to make really reliable and easy-to-use heating boilers.

After analyzing the reviews of people who have already bought and use the products of the Czech manufacturer, it is possible to identify the strengths of these heaters:

- A special funnel-shaped opening and a wide flap blocking access to the combustion chamber facilitate the loading of firewood.

- The presence of special grates allows not only to burn fuel with a high level of humidity, but also to easily clean the combustion chamber from the accumulated ash there.

- The use of special non-asbestos insulation makes Dakon boilers safer for humans and the environment.

- Modern design meets the most progressive trends in this area.

- Automatic power control using mechanical non-volatile thermal valves or high-tech electronic climate control systems makes the use of boilers not only convenient, but also economical.

And finally, you need to note the cost. Despite the high technical characteristics and consumer properties, Dacon boilers belong to the average price category.

The minimum cost of a steel boiler with a horizontal fuel load starts from 40 thousand rubles. More economical and reliable cast iron varieties will cost you in the amount of 65 to 95 thousand rubles.

Well, the most advanced pyrolysis models cost from 111 thousand rubles.

This is much less than similar products from other European brands. It is cheaper to buy only the equipment of domestic manufacturers, and it, regrettably, is not yet very popular.

Conclusion

If, for any objective or subjective reasons, you have firmly decided to use firewood or other solid fuel as the main source of energy, then you will not find better boilers than produced by the Czech company Dakon. There are better and more innovative models, but their cost is much higher. You can learn more about the climatic equipment of European manufacturers from the video presented to your attention.