Solid fuel boiler for heating a private house: features of

Today, heating a private house with a solid fuel boiler is one of the most sought after solutions. And this is not surprising, since not every cottage or cottage can be connected to the gas distribution pipeline.

The advantages of this type of equipment

Modern heating equipment operating on solid types of fuel has many advantages, among which we note the following:

- relatively low price of the device;

- possibility of operation with various types of pipelines and heating radiators;

- simple efficient and reliable design;

- the possibility of using several types of fuel, including firewood, fuel briquettes, pellets, coal, sawdust, garden and garden waste, including branches left after pruning trees;

- high efficiency and, as a result, the possibility of high-quality space heating without excessive fuel costs.

However, the use of a solid fuel boiler has several disadvantages that need to be taken into account when choosing and purchasing equipment:

- arrangement of a separate boiler room and an extension for storage of fuel materials will be required;

- Most solid fuel boilers do not imply the possibility of automating the heating process, and therefore it is necessary from time to time to keep an eye on the equipment and throw firewood.

Main varieties

Modern solid fuel boilers for the house in accordance with the operational features are divided into the following types:

- modifications with self-made fuel;

- versions with automatic fuel supply;

- heating furnaces as a separate group of equipment.

Modifications with manual submission, in turn, are of the following types:

- traditional classic heating boilers for solid fuels for the home;

- equipment operating by the pyrolysis reaction;

- heating boilers long burning solid fuel.

Also, the instruction for selecting and operating solid fuel boilers depends largely on their energy dependence. Classic devices with manual fuel supply and manual ignition do not feel the need for electricity.

More advanced automated devices require a constant supply of electricity. In this case, electricity is necessary for ignition and fuel supply and for stable operation of the forced exhaust system.

Modern solid fuel boilers, as well as other heating equipment, are divided into single-circuit and double-circuit modifications.

- Single-circuit modifications are intended only for heating the coolant for subsequent supply to the system.

- Dual-circuit modifications are more functional, since they heat not only the coolant, but also water. Dual-circuit boilers can be equipped with two or one heat exchanger.

If there are two heat exchangers, the water and the coolant can be heated to the required temperature at the same time. If the heat exchanger is one, then the coolant and water are heated alternately.

Depending on the type of fuel used, the power of domestic boilers can reach from 10 to 80 kW. The greatest power is achieved when coal and coke are used as fuel.

Constructional features of classic boilers

Classic solid fuel boilers for a private house is a wide range of equipment. But, in fact, all these devices are not much different from a conventional furnace.

The only significant difference is the presence of a built-in capacity of the circuit through which the coolant circulates. For a long time, such structures have been widely used both in private houses and in small stokers at residential or public buildings.

Important: Statistics on the use of solid fuel boilers have a lot of examples when home-made cheap plants show no less performance than factory units.

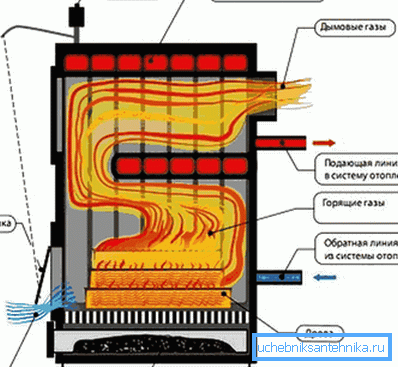

The principle of operation of a classic solid fuel boiler is simple - a certain amount of fuel is laid in the furnace, which, during combustion, releases the energy necessary to heat water in the lower part of the circuit (in the heat exchanger).

Sizes and configuration of heat exchangers, both steel and cast iron may vary significantly. And this largely determines the power and performance of the equipment.

Important: When choosing a boiler, you should pay attention to the material from which the heat exchanger is made. Products made of cast iron are characterized by greater efficiency and power. On the other hand, steel products are stronger, more reliable and, as a result, more durable.

Solid fuel boilers are equipped with an expansion tank, which is an essential element to ensure natural circulation. In more complex installations, the circuit can be improved by using a circulation pump, which contributes to a more stable pressure maintenance.

Features of automation of heating equipment

In order for the heating of a country house by a solid fuel boiler to be less dependent on human participation, high-tech automation systems are used. Of course, due to the use of such systems, the price of equipment increases significantly.

Among the elements of automation, we note the following:

- Devices that supply fuel to the firebox are a hopper with a metering device.

- Devices responsible for the grate reversal.

- Devices for cleaning the ash pan.

- Separate modifications of the equipment provide the ability to remote control via the Internet or mobile telephony.

Due to the use of automation systems, the boiler operates autonomously during the week.

Important: Due to the use of dispensers, the boiler loses its versatility in terms of the types of fuel used. That is, if the feeder is designed for coal or pellets, it is most likely that you will not be able to heat wood.

Conclusion

Now you have a general idea of what are solid fuel boilers for the home. Moreover, you know how these devices work, and what are the advantages and disadvantages of a single equipment.

There are questions that need clarification? In this case, more useful information can be found by watching the video in this article.