Solid fuel boilers: how to choose a climatic equipment for a

Heating devices operating on wood or coal, have been known for more than 100 years. And their ancestor - the furnace - and even longer. But nowadays, solid fuel heating boilers are widely used to design climate networks of private dwellings in the absence of the ability to conduct gas or unwillingness to mess around with connecting three-phase electricity.

The principle of the device

Any solid fuel boiler consists of several main blocks, differing only in their versions:

- firebox in which the selected type of fuel is burning;

- heat supply and removal systems that are necessary to transfer heat from the burned wood or coal to the selected heat carrier (water or antifreeze);

- systems for the removal of combustion products, through which smoke and substances harmful to humans are expelled;

- control systems that regulate the operation of the boiler depending on external conditions and prevent the heater from failing due to a violation of its operation.

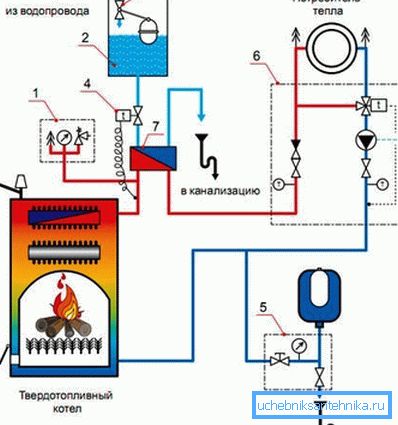

The fuel burned in the furnace generates heat and heats the walls of the combustion chamber. On the reverse side there are heat exchangers installed in which the fluid circulates. After heating, hot water rushes through the pipes to the radiators, where the exchange of thermal energy between it and the air in the room takes place. This is in brief the scheme of water heating.

It is advisable to choose boilers whose heat exchanger is made of thick metal. The thickness of the water layer in it should exceed 3-5 cm. Otherwise, if the coolant circulation rate is insufficient through pipelines, water may boil in the boiler (especially if coking coal is used as fuel).

To avoid this, a circulating pump will help, which accelerates the flow of fluid depending on the commands from the electronic controller of the solid fuel boiler.

Also, to prevent accidents, some heaters are equipped with a special cooling circuit. This is a special coil connected to the cold water supply. As soon as the temperature exceeds the permissible level, the shut-off valves open and cold water lowers the temperature of the overheated metal.

If you do not have the opportunity to connect the boiler to the central water supply (which is often the case in rural areas), then you need to install a special container in the boiler room in which the volume of cold water sufficient for cooling the equipment will be stored.

Equipment classification

Solid fuel boilers are produced in many countries around the world. And each manufacturer (Visman, Cooper, Karakan, YaIK and so on) tries to put on the market equipment that is different from the products of competitors. As a result, the choice of the consumer is presented with such a wide range of heaters that it is quite difficult for an inexperienced person to understand them.

In order not to regret the choice made after the purchase, you should carefully understand what solid fuel heating boilers are, what distinguishes Russian, Ukrainian and German units, why it is more profitable to buy gas generator models, although their price is much higher and so on.

For the sake of convenience, we will distribute the existing heating boilers for solid fuels into groups depending on various classification criteria.

Heat exchanger material

This is one of the main parameters by which to choose a heating device for individual use.

There are two main varieties.

- Solid fuel heating boiler with steel heat exchanger. An example of such equipment is the Russian Dobrokhot (Barnaul), the Polish SAS or the Austrian

Steel boilers are distinguished by low cost, low weight, but also a limited service life. These are mostly low power devices used for individual needs.

Bright representative - Zota-MIX. This model tops the ranking of solid fuel boilers used for the construction of small autonomous heating networks for combined fuel.

Note! The simplest steel boilers operating on solid fuels can also be made by hand. Their drawings and instructions for making for anyone are not a secret. You only need to have the appropriate skills and be able to work with the welding machine.

However, remember that this design will have low efficiency. Even the simplest and cheapest solid fuel boiler Prometheus will be much more economical and efficient to operate than home-made.

The combustion chamber and heat exchangers of more expensive models of steel boilers, for example, the German Viessmann, are coated with special refractory clay or coated with bricks. This significantly extends the service life of the equipment and slightly increases its efficiency.

- Solid fuel heating boiler with cast iron heat exchanger. The most popular and well-known cast iron solid fuel boilers Lamborghini (Italy), Protherm-Beaver (Czech Republic).

The combustion chamber and heat exchangers of such devices are made thick enough to protect the cast-iron parts from destruction as a result of shock loads. Therefore, the weight of the boiler can exceed 250 or even 300 kg. Install it only on a solid concrete base.

The power of cast iron units is not less than 20 kW, so they are used for heating of large enough for the area of residential houses or commercial premises.

Type of energy used

Solid fuel heating boiler, as the name implies, is designed for burning fuel, laid in the furnace in solid form. But it means not only banal firewood.

The main types of energy carriers that can be used to heat a dwelling using the described equipment are shown in the table.

| Type of fuel | Description |

| Firewood | This is the most common type of fuel due to its general availability and low cost. To achieve maximum efficiency, use wood with the lowest moisture level. A typical representative of a wood boiler is the Kostroma Bourgeois-K, known to many for its low cost and ease of use. |

| Coal | To heat the coolant can be used as brown and coking coal. Remember that when burning, this type of fuel forms a flame with a higher temperature, so it is advisable to give preference when buying cast iron boilers or steel models, the combustion chamber of which is protected by chamotte (refractory clay). |

| Pellets | This fuel is made from waste wood. Excellent burning support. It is often used with systems that automatically feed energy into the combustion chambers. A striking example of pellet equipment is the Russian Smoke, but fuel pellets can also be burned in many other models of HVAC equipment. |

| Universal | Devices can work on different types of fuel. Moreover, some models of equipment (for example, Kliver-14 produced by the well-known Russian plant operating under the trademark Kliver) can be converted to use other types of energy carriers: electricity, gas, diesel, and so on. |

Note! Firewood or wood waste is often used for burning in pyrolysis boilers. In this case, special requirements are imposed on the quality of energy carriers. For example, the gas generator solid fuel boiler Stropuva effectively works only when the moisture content of the fuel is not more than 15-20%.

Pyrolysis boilers

Heating boiler for solid fuel has one very big drawback, limiting its wide distribution: the need for periodic and fairly frequent manual loading of fuel. Some units require a new portion of firewood every 3-4 hours, which, you see, is inconvenient.

To avoid this, so-called gas-fired boilers have been developed, which require loading once every 2-3 days and burn fuel more efficiently. Such units are produced by many manufacturers. One of the most inexpensive are: Lithuanian Stropuva and the Russian Spark.

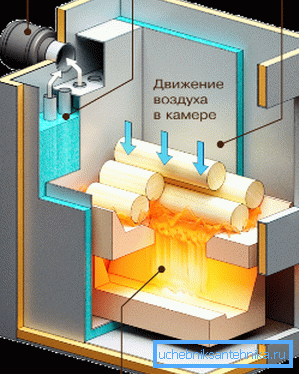

The principle of the gas boiler is as follows:

- Firewood is loaded into the upper combustion chamber, where they do not burn, but smolder, emitting a so-called pyrolysis gas, which is then fed to the lower furnace.

- The second combustion chamber is designed exclusively for burning through the formed gas. Thus, the fuel is burned as if twice, which significantly increases the efficiency of the equipment.

Boilers for heating on solid fuels, working on the pyrolysis principle, have many undeniable advantages:

- in comparison with classical devices, they emit a greater amount of thermal energy when burning the same amount of fuel;

- firewood or pellets are burned to the fullest extent possible; only fine ash remains in the ash pan, which must be removed no more than once every seven days;

- special automatic equipment installed on the boiler makes it possible to fine-tune the parameters of its operation, achieving maximum comfort in heated premises with minimal heating costs;

- fuel in their combustion chamber must be put once in 12-30 hours, depending on the design.

Note! If the heating system installed in your house with a pyrolysis boiler does not have a circulation pump regulating the coolant current through pipes and radiators, it is imperative that the solid fuel boiler is protected from overheating. Otherwise, the liquid in it from the high temperature may boil and the heat exchanger to crack, which will damage the entire unit.

Tips for choosing

Before purchasing a solid fuel boiler, pay attention to such nuances:

- the presence of multiple combustion chambers - allows you to burn fuel more efficiently;

- the presence of a second circuit for heating water - makes it possible to equip the house with hot water supply;

- the ability to install an automatic feed hopper - in this case, the boiler will need to be serviced every 7-10 days, not more often.

Conclusion

As a conclusion, one thing should be noted that allows the most efficient operation of the climate network, of which the boilers described in this section are a part: it is desirable to install control electronics for solid fuel boilers that regulate their operation depending on the temperature outside and in the house, time of day and season . So you can economically use energy.

For more on this, see the video below.