Solid fuel boilers kcm: simplicity, reliability and

In the shops for the sale of climate equipment to choose from a huge number of different devices operating on certain types of energy. However, among solid-fuel units, heating boilers of the КЧМ of the Kirov plant, which will be discussed below, are deservedly respected. Their legendary strength, as well as the optimum price-quality ratio, is known to every specialist in the design of heating systems.

Description of the equipment

Design features

Limited Liability Company Kirovsky Zavod has been producing various products from cast iron for more than 260 years.

The range of products manufactured by the company includes:

- cast iron baths;

- pallets;

- water heaters;

- parts for the manufacture of fireplaces and stoves;

- decorative elements made of cast iron (sewer manholes, storm lattices);

- art cast.

However, the most well-known products of the plant are solid fuel boilers of CWM, which are characterized by increased durability, high efficiency and democratic cost.

These units have unique design features that are rarely found in similar equipment from other manufacturers:

- Sectional heat exchanger. Most solid fuel boilers are equipped with integral heat exchange units and, accordingly, have a fixed power.

The solid fuel boiler KCM has several cast-iron sections through which coolant circulates. By increasing or decreasing their number, you can adjust the power without making additional changes to the design.

- Versatility. The main energy source for the boiler, as the name implies, is solid fuel - wood or coal. However, if necessary, the device can be easily upgraded for burning gas, diesel, used engine oil, and so on.

It is only necessary to retool the burner, which will take quite a bit of time, and connect the pipeline that supplies the energy carrier.

Worm bunkers are also available, which are mounted on KCM boilers. With their help, you can equip the most autonomous heating system on solid fuel, which will be pellets or woodworking production waste.

Tip! Solid fuel boiler KCM can be used for installation of the climate system of a private house in the village where the gas has not yet been conducted. Later, when the supply gas pipeline is reached to your section, the equipment can be easily reconfigured to another type of fuel without dismantling the heating system.

For household climatic nets for individual use, the KCM-5 heating boiler is most often used; it has 3 or 4 heat exchanger sections and can easily provide a house with an area from 150 to 200 square meters with heat.

Structurally, the heating unit of the Kirov plant consists of the following elements:

- Sectional Cast Iron Heat Exchanger. This is the main element of the boiler, where, due to the burning of any fuel, the heating medium entering the boiler is heated.

The inlet to which the heating system is connected is located in the lower part of the first section. Accordingly, the outlet channel is located at the upper edge of the latter.

- Doors. The boiler has three of them.

All are located on the leading edge of the heater, but each of them has its own differences:

- loading - needed for fuel loading, has several openings providing access of secondary air;

- ash - serves to remove ash and ash, as well as adjust the volume of air flow entering through the grate into the combustion chamber;

- shurovochnaya - necessary to maintain the combustion mode.

Note! The volume of air entering through the ash chamber can be adjusted either manually (with a screw) or with an electronic thrust regulator controlled by thermostats.

- Smoke Pipe. Located in the back of the boiler. Equipped with a damper that allows you to adjust the volume of exhaust gases.

- Housing. The peculiarity of the boiler is that its entire body is protected by heat insulating material. This allows you to increase work efficiency and protect the person working with the device from burns. To prevent corrosion, the casing is powder coated on top.

- Thermometer. It is part of the security system. It measures the temperature of the coolant in the sections of the heat exchanger and displays the readings on the front panel, where they are easy to read. In case of exceeding the permissible rate, measures should be taken immediately to cool the boiler.

Advantages and disadvantages

Like any other device invented by man, the boiler KCM-5 has both advantages and disadvantages.

The positive aspects of using the described climatic equipment include:

- Long service life. Thanks to high-quality cast iron and a robust housing, the heating device will serve you for at least 25 years, practically without changing its consumer properties.

- Versatility. As mentioned above, with the help of the supplied or purchased parts, you can convert the boiler to use almost any fuel.

You can change the types of energy used depending on their cost, availability at the moment and just your own desire.

- Ease of maintenance. The design of the cast iron boiler of the Kirov factory is so simple that you can easily perform routine maintenance yourself without attracting expensive specialists.

In addition, having small skills in plumbing, you can do it yourself to fix minor problems. Although, it should be noted, any malfunctions in the operation of the equipment are extremely rare.

- Extensibility. The amount of heat energy produced by the boiler depends on how many sections the heat exchanger has. The power of the boiler can vary in the range from 20 to 80 kW. This is one of the most flexible solid fuel solutions for individual heating networks.

- High efficiency. Due to high-quality thermal insulation of the hull and other engineering solutions, the efficiency of the boiler at the Kirov factory is at a fairly high level - at least 78%.

Note! Such performance indicators can be achieved using only high-quality fuel. So, the moisture content of wood should not exceed 20%. As for coal, it is advisable to buy anthracite with a fraction of up to 60 mm.

Considered boilers and disadvantages considered. One of the most important is the high consumption of solid fuel during operation and, accordingly, the short time of continuous operation without human intervention.

In addition, if we compare the efficiency of the boiler of the KChM with the pyrolysis (gas generator), then the first ones are lagging far enough.

And the last - the need for periodic cleaning. No matter how well the firewood is burned in the furnace, after them there remains a large amount of ash and ash, from which also need to be disposed of manually.

Boiler installation

During the installation of the climatic equipment described here, it is necessary to strictly comply with the requirements stated in the installation instructions. This will not only increase the service life of the unit, but also protect the people serving it from injuries and other troubles.

So, during the placement of the boiler KCM in the boiler room, pay attention to the following nuances:

- The distance from the rear edge to the nearest wall of the room must be at least 2.5 meters. It is also necessary that the side edges should be no less than a meter from the walls of the room.

Free access should be provided to the rear nozzle, through which the products of combustion are removed: the dimensions of the space required for this are at least 40 by 40 cm.

You need to take care of the convenience of loading fuel. To make it convenient for the stoker to move, the free area in front of the front of the heating device should not be less than 1 square meter. meter. This will make it easier to pop up firewood and clean the ash pan from fuel residue.

- Fire safety measures must be observed. The floor before installing the boiler on it should be covered with non-combustible material. The edges of the protective pads must be at least 40 cm in size.

Tip! Best during the construction of the boiler room to make a special pedestal of concrete, reinforced with metal rods. So the boiler will have a reliable base, which is also absolutely fireproof.

Also in order to avoid a fire near the unit it is forbidden to store fuel. It is advisable to arrange the main storage separately from the boiler house, and the daily supply should be located no closer than half a meter from the operating boiler.

- As a coolant for the heating system, it is desirable to use softened water filtered from mechanical impurities.

It is advisable not to use hard to avoid the formation of scale in the boiler heat exchanger and pipes. You can pour antifreeze into the heating network, but before that you should read the instruction manual and make sure that the liquid does not harm the cast iron parts of the boiler.

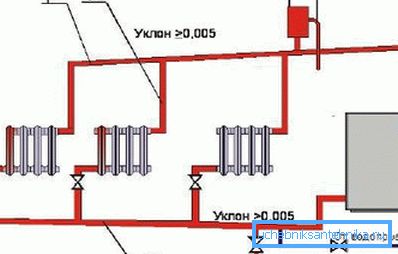

The connection procedure itself is as follows:

- first, the boiler is installed on a pedestal or gasket, the level is checked and the supports are fixed (it is necessary to achieve complete stability of the unit on the stand, the slightest deviation from the horizontal can lead to the formation of scale in the heat exchanger and reduce the service life of the equipment);

- pipes are connected to the inlet and outlet connections (it is advisable to do this through valves, so that you can shut off the coolant current and dismantle the unit in case of a breakdown or for replacement);

- A vertical chimney is connected to the nozzle responsible for the removal of combustion products (it is desirable to fix a special part in the lower end of the pipe that is necessary to collect the condensate that forms on the walls during the boiler operation);

- after installation, the system is crimped (for this you can use a special pneumatic device).

Conclusion

Solid fuel boiler KCHM - a great device for home use as a heating unit. But in order for the climate system to work normally, you need to pay considerable attention to the installation of pipes, and the choice of the expansion tank, and the installation of radiators.

On how to properly perform all of the above actions, you can learn from the video in this material.