Solid fuel boilers ochag: a review of models and the

Heating at home can be done in different ways, but now the most common radiator circuits and floor heating systems. Both in one and in another case gas and solid fuel boilers are perfectly suitable. Of course, there are other brands of boilers, as well as other types of fuel, such as diesel or electricity.

But we will not be able to pay attention to everything at once, therefore, our goal in this article is only one manufacturer. But we will not only make a short review of the models, but also tell you about the principle of their work, and also show you a short video clip.

Principle of operation

Solid fuel

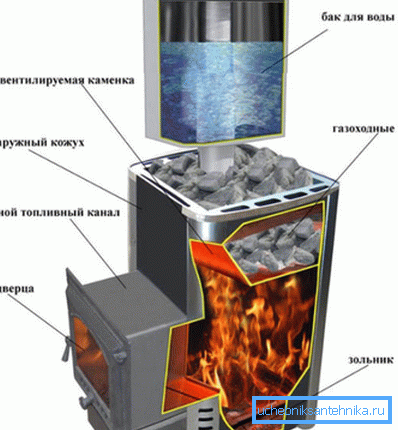

- Solid fuel units are widely distributed in Russia and are used not only for heating houses, but also are successfully used in steam baths.. The device of the traditional device is quite simple - a heat exchanger is mounted on the fuel compartment, which can be either in the form of a tank or in the form of interconnected tubes. The intensity of combustion can be adjusted simply - the doors of the furnace and the ashpit, but in the latest models there is a whole system of valves that regulate the air flow.

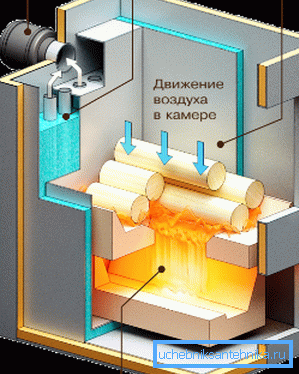

- The gas generator model working on the principle of pyrolysis combustion works in a completely different way, that is, the fuel in the unit is burned with almost no residue, which significantly increases its efficiency. Thus, in the firebox, firewood or coal lights up, after which the oxygen supply is partially blocked, which causes abundant smoke (pyrolysis) and these products of combustion get into the second afterburner chamber, where hot air stimulating combustion is fed through a special channel. Of course, the price of such models is much higher, but the fuel consumption is 3-4 times lower, moreover, the efficiency increases, so the savings are obvious.

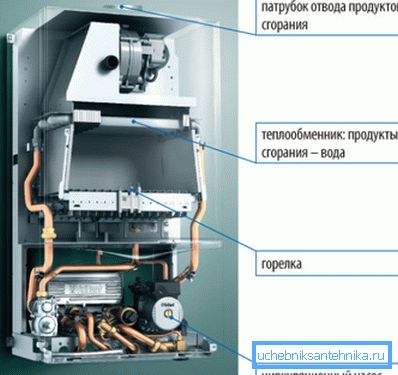

Gas

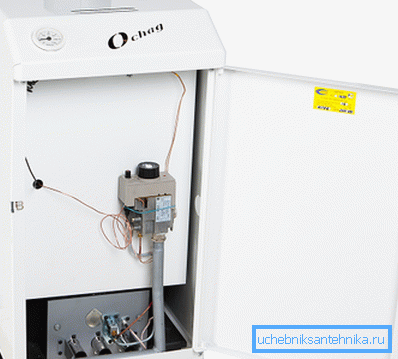

- Convection-type gas boilers, which are also called traditional, operate on the principle of heating a heat exchanger with a burner flame and direct forced removal of gases from the combustion chamber. For the longest use, the instruction manual recommends adhering to the optimum temperature range of 60-80? C - this is important, since the point of condensate formation is 55-57? C and when it is deposited on the heat exchanger, the metal walls are destroyed due to the presence of acids there.

Note. The heat exchangers themselves are most often made of heat-resistant steel, but there are also options made of cast iron and aluminum, moreover, they can be separate and bithermic (pipe in the pipe).

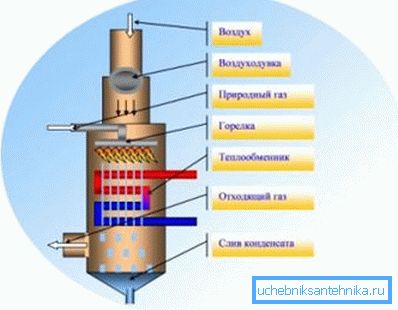

- Condensation gas boilers, which are also called low-temperature boilers, work according to a slightly different principle - there hot air from the combustion chamber is not diverted to the street, but is used for the secondary heating of the heat exchanger. When the critical point of condensate (55-57? C) is reached, the acidic moisture simply precipitates, from where it is discharged through a special channel through the filters - this allows the unit to operate at an optimum temperature of 30-50? C. Work in this mode is very convenient for floor heating systems and raises the efficiency of installations up to 108-111%!

Recommendation. For a mixed heating circuit (radiators - underfloor heating) it is more advantageous to use traditional models of convection type with a three-way valve embedded in the system, since the constant operation of the unit in such cases is much closer to the bar 60-80? C.

Some models

The AKTV-12 modification of the floor type has the corresponding power, according to the digital value on the marking -12 kW, and it is recommended to use coal, anthracite and firewood as fuel. The volume of water in the tank here is 35 liters, the working pressure is 2 bar, the heat exchanger is made of heat-resistant steel, the exhaust gases are discharged through the chimney, the efficiency of burning coal is at least 65%.

The convenience of this model is in the presence of the cooking plate, and its overall dimensions (height / width / depth) are 740x450x760 mm, respectively, with a total weight of 95 kg.

The gas generating (pyrolysis) solid fuel heating system of the CENTER is made of 6 mm thick sheet steel and steel pipes, which streamline (systematically distribute) the movement of gases and their burning. Due to this, the efficiency of units of this type is 89%.

| Options | unit of measurement | IN 1 | ||||||

| Power | kw | ten | 13 | 17 | 25 | 31 | 38 | |

| Heated area | m2 | 100 | 130 | 170 | 250 | 310 | 380 | |

| Heat exchange surface | m2 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 | 4.0 | |

| Loading volume | kg | 50 | 60 | 70 | 80 | 90 | 100 | |

| Chimney | cm2 | 150 | 300 | 300 | 300 | 300 | 300 | |

| Thrust exhaust | mm / H20 | 1.5-3.0 | ||||||

| Chimney length | m | four | 4.5 | 4.5 | 5.0 | 5.0 | 5.5 | |

| total weight | kg | 300 | 340 | 394 | 456 | 480 | 520 | |

| Dimensions | height | cm | 135 | 140 | 145 | 160 | 160 | 185 |

| width | 58 | 58 | 60 | 65 | 65 | 68 | ||

| Depth and hog | 63 + 20 | 76 + 20 | 78 + 20 | 80 + 20 | 85 + 20 | 91 + 20 |

Convection gas boilers of the CENTER can be either single-circuit or double-circuit, and this difference is noted in the labeling, that is, the abbreviation KSGV means the presence of two circuits, and the KSG - one, there are three degrees of protection. Rated operating power for various modifications can be 7, 10, 12.5, 16, 20 and 25 kW, and is designed for heating areas of 70, 100, 125, 160, 200 and 250m2 respectively.

Note. Currently, the production association does not produce gas boilers of this brand of condensation type.

Conclusion

Installation of any solid fuel or gas domestic boiler for a heating system with your own hands is quite possible, but for this you need to understand the heating systems, otherwise you just can not make the correct connection of the unit. In addition, in the case of gas models, you definitely need to invite a specialist with a license for the examination and official launch - this will allow the warranty period to run out from this time.