Solid fuel boilers viadrus: wood burning devices, pyrolysis

The most common type of fuel for most of the autonomous heating systems of private houses, for many years, is domestic natural gas, which is supplied to consumers through a centralized gas supply system. However, not all settlements of our country are connected to the centralized gas supply. In such cases, it is advisable to use autonomous boiler equipment operating on alternative fuels, for example, Viadrus solid fuel boilers, which can run on coal, wood, and also pressed pellets made from wood or agricultural plant waste.

Overview of solid fuel boilers Viadrus

The use of solid fuel boiler equipment, in addition to solving the issue of gas supply, also has an economic rationale, since the price of these types of fuel is significantly lower than the cost of domestic natural gas.

To study this issue in more detail, in this article, the main types of solid fuel boilers from the Czech manufacturer, Viadrus, which has been manufacturing boiler equipment since 1920, will be presented as an example.

Wood burning boilers

The main distinctive feature that all solid-fuel Viadrus boilers have, regardless of the type of working unit and type of fuel used, is the possibility of sectional increase in design capacity.

The working area of the boiler is assembled from several cast-iron sections, which are interconnected by means of bolted connections with special nipple nuts. Installing additional sections allows you to increase the size of the combustion chambers, ashpit and water heat exchanger, thereby achieving an increase in the total capacity of the unit.

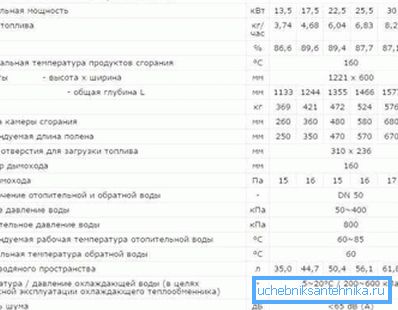

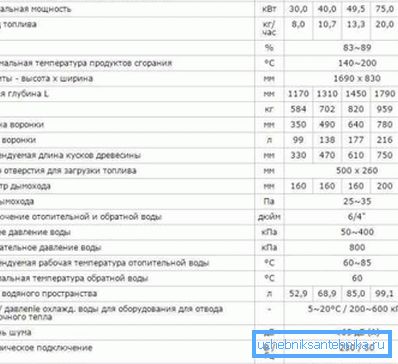

The main technical characteristics of wood burning direct-burning boilers, depending on the number of sections used, are indicated in the table presented in the figure below.

Among the main aspects that should be paid attention to when buying, the following consumer qualities can be noted:

- Solid fuel boilers of direct combustion are the simplest version of boiler equipment from this manufacturer, thanks to which a relatively low cost, high level of reliability, as well as the ability to install and connect with your own hands, without the involvement of qualified professionals.

- The use of such units is allowed in closed water heating systems with an installed pump, providing forced circulation of the coolant.

- For durable and safe operation, all models are equipped with a system of protection against water overheating, as well as a water cooling system of the grate.

Note! For normal operation of boiler units of this type, the relative humidity of wood should not exceed 20%, and the maximum diameter of the log should not exceed 100 mm.

Pyrolysis boilers with afterburners

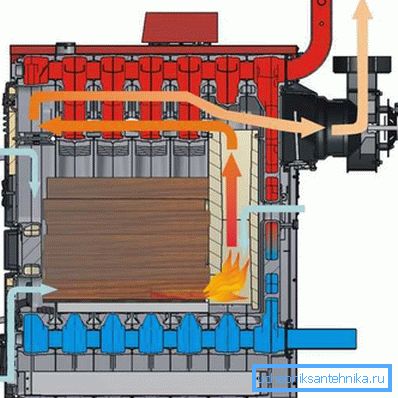

Pyrolysis, or in other words, the gas-generating solid-fuel boiler Viadrus also assumes a sectional increase in power, but differs from direct combustion models in that it uses the dual-chamber principle of fuel combustion.

- In the first, loading chamber, which has a relatively large volume, gradual drying and degassing of wood is carried out, and in its lower part, i.e. in the recovery zone, there is a slow combustion with a limited amount of air at a temperature of + 560 ° C, which results in the release of volatile substances and combustible wood gases.

- In the second afterburning chamber, the process of mixing volatile substances and combustible gases with secondary atmospheric air occurs., as a result, they burn at high temperature, which can reach +1200 ° C.

The pyrolysis principle of burning wood, coal, or other types of solid fuels makes it possible to achieve higher temperatures and, accordingly, to get more thermal energy from each conventional unit of used fuel. This, in turn, significantly increases the efficiency of boilers, and also leads to significant savings in fuel materials.

The pyrolysis solid fuel boiler Viadrus, depending on the number of working sections, can be equipped with an electronic or thermostatic control system.

- The electronic system is installed on boilers that have from 3 to 5 working sections. Such a system allows for more flexible adjustment of operating modes, but for its operation a constant connection to the electrical network is necessary.

- Thermostat control system is installed on more powerful equipment, which may consist of 6-8 working sections. It is absolutely non-volatile, and allows you to automatically regulate the flow of fresh air and the removal of exhaust gases, as well as to control the temperature of the working area of the boiler and the temperature of the coolant in the heating system.

.

Note! For normal operation of pyrolysis boilers, the relative humidity of the fuel should not exceed 20%, and the temperature of the return water in the system should not be below +60 ° C.

Pellet heating boilers

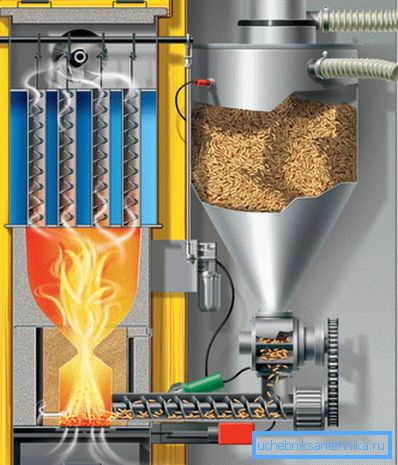

Relatively new and most economical development is considered to be a solid fuel boiler Viadrus, which works on pellets. They are compressed granules made from dried and shredded waste wood or tops and cake crops.

Increasing the working capacity of pellet boilers is also performed by installing additional sections, and the adjustment of operating parameters can be carried out in automatic or manual mode.

- In the process, a certain stock of pellets is stored in the fuel bunker., from which, with the aid of a screw feeder, they are automatically fed into the burner.

- In the burner, when intake of primary air and high temperature, pellets intensively smolder, releasing volatile substances and combustible gases.

- Evolved gas and saturated hydrocarbons enter the combustion chamber., where in the environment of secondary atmospheric air, their complete combustion occurs with the release of a large amount of heat.

- The exhaust gases passing through the heat exchanger give a significant amount of their heat to the water heating circuit., and at the outlet they have a temperature of not more than +160 ° C.

All pellet boilers are equipped with an electronic control system that allows you to fully automate its operation. In addition, they are equipped with a coolant overheat protection system that automatically shuts off the burner when the temperature reaches + 96 ° C, as well as antifreeze protection system that automatically turns the burner on when the coolant is cooled to a temperature of + 5 ° C.

Tip! The factory instruction manual for this type of boiler recommends the use of fuel pellets with a diameter of 6 to 10 mm, with a relative humidity of up to 12%, and specific ash content up to 1.5%.

Conclusion

Finally, it should be noted that in addition to these types of boilers, this company also produces universal boiler equipment that can operate on combined types of solid fuels, that is, simultaneously on wood, coal or brown coal, and pressed fuel briquettes.

To get more information about this equipment, you can watch the video at the end of this article, or read similar materials on our website.