Solid fuel pyrolysis boilers: device, principle of

Pyrolysis solid fuel boilers long burning are becoming increasingly popular due to its features and the ability to economize on fuel. Modern technologies allow the use of units in automatic mode, like gas boilers, which makes their operation more convenient. We will describe how pyrolysis boilers are arranged and what are their main features.

Gas fired boilers for solid fuels

Device and principle of operation

The pyrolysis solid fuel boiler works on the principle of generating combustible gas from solid fuel when it is heated in the absence of oxygen. Then the released gas is fed into the combustion chamber, where it is enriched with oxygen and burns. The process of burning isolated volatile substances and heating the coolant resemble the work of a regular gas boiler.

Pyrolysis is the process of decomposition of substances into components when heated. The most suitable type of fuel for pyrolysis is wood, lignite and fuel briquettes from wood waste. When heating wood to temperatures of 200 - 800 degrees and above, they emit a mixture of hydrocarbons (benzene, acetone, furan, methyl alcohol), nitrogen, carbon monoxide, acetic acid and hydrogen.

Note! Strictly speaking, any burning of wood occurs through pyrolysis, since it is not carbon that burns, but wood decomposition products - hydrocarbons.

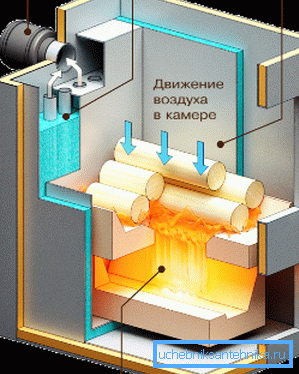

In the boiler, a draft is created by the operation of a smoke exhaust or a blower fan, and the volatile decay products of wood are entrained in the combustion chamber. There air is mixed in and ignited. Heat is released to warm up the coolant - water, air or other matter.

As a rule, the boot chamber is located on top, and its floor is the grate. Firewood is loaded into the loading chamber and set on fire, then the chamber is closed and a blower fan or smoke exhauster is turned on, and a thrust occurs, which directs the air flow through the firewood and the grate into the lower chamber. In the lower chamber, the mixture of volatile products is enriched with fresh air and ignited.

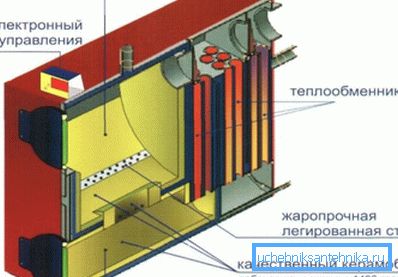

Burning gases pass through a heat exchanger through which water circulates and are removed through the chimney. All parts of the furnace and gas channels are made of heat-resistant alloy steel and porcelain concrete, heat exchangers - from copper or other metal with high thermal conductivity.

Note! By adjusting the flow of primary air into the loading chamber, it is possible to influence the intensity of combustion, moreover, this process can be automated through feedback from thermal sensors in the heating system. Thus, manufacturers can make pyrolysis boilers for solid fuel with automatic control.

Special features

Heating pyrolysis boilers have a number of characteristic features that should be borne in mind when buying a unit.

The most significant properties are:

- The unit works by forced traction.. Smoke exhauster or fan produces a double top blast, without which the process of pyrolysis and combustion of gases will not work. Conclusion: the device can work only in the presence of voltage in the power supply network of the fan;

- The instruction imposes a rather strict requirement on the moisture content of the fuel - it should not exceed 20–35%, otherwise the water vapor will dilute the hydrocarbon mixture and the combustion will stop;

- The loading range of the primary chamber should be 50 - 100%, since it is in this mode that the efficiency is achieved at the level of 85 - 92%. Manufacturers do not use pyrolysis solid fuel boilers with a load of 30% and below;

- The unit can be duplicated gas and oil boiler. If the humidity of the wood is high or there is no voltage in the network, this decision will save you from frost.

Note! It makes sense to acquire a pyrolysis unit if you have a source of cheap firewood and conditions for their normal drying and storage. Otherwise, the gas boiler will be more profitable.

Advantages and disadvantages

The advantages of gas generating plants include the following qualities:

- Adjusting the combustion process allows you to work for a long time with one bookmark of firewood. For devices with lower burning this time is up to 12 hours, with the upper one - up to 30 hours. Burning the same amount of fuel in a conventional furnace is 3 to 4 hours;

- The possibility of automatic process control and regulation in real time;

- Complete combustion of the fuel saves firewood and reduces waste in the form of ash, tar and other compounds;

- The two-stage scheme of fuel combustion allows to increase the efficiency of the installation;

- The high temperature in the upper chamber suppresses the release of CO, which makes the device more environmentally friendly.

Note! As a result of this approach, it is possible to achieve a noticeable economic effect (7–10%) and improve the usability of heating due to automatic control of the combustion process.

The disadvantages of the gas generator boil down to its features:

- High price. Modern solid fuel systems cost 2 or more times more expensive than competitive devices;

- Dependence on electricity;

- Demanding on the condition of the fuel - its humidity;

- At low loads, combustion becomes unstable;

- The inability to automatically supply fuel.

Note! For the successful operation of the gas generator boiler, the competent organization of the entire heating system plays an essential role. With proper wiring, careful selection of the device and good automation of one bookmark of firewood, there is enough work for a day.

Conclusion

Boilers for solid fuel with pyrolysis are more economical and high efficiency compared with wood-burning stoves. At the same time, when purchasing a device, one should take into account its features, otherwise its use may become unprofitable (see also the article Borinsky gas heating boilers - models and their features).

Watch the video for a more complete impression and a better understanding of the topic.