Steam heating: the scheme, the materials used and the method

Usually hot water is used as a heat carrier in residential heating systems, but sometimes it is replaced with steam. The scheme of steam heating is somewhat different from the traditional solution, because you should pay close attention to its analysis. Only knowing all the nuances, you can create an effective project and correctly implement it.

Analyzing the design

Features of the system

In itself, steam heating is quite simple:

- The boiler acts as a water heater. (electric, gas or solid fuel). In some cases it is possible to build a system using a furnace, but then it needs to be modernized accordingly.

- In the heater, water is brought to a boil, forming a large volume of steam that is under considerable pressure..

Note! The most common are low pressure systems designed for 100–150 kg / m.2. Also in private homes can be used vacuum-steam heating (up to 100 kg / m2), and in industry sometimes use structures that can withstand more than 600 kg / m2.

- Steam enters the pipelines through which it penetrates radiators installed in the premises. Here there is a redistribution of heat: the pipes gradually cool down, heating the surrounding air.

- After cooling below a certain level, water is collected in the form of condensate and returned to the boiler..

- Separately, it is worth noting that the air displaced from the system by steam is discharged to the outside through a special exhaust pipe..

Depending on the method of returning condensate to the boiler, there are:

- Heating systems of the closed type. In this case, the cooled water enters the boiler directly through the pipes.

- Open type systems. Condensate initially accumulates in a separate tank, and then is pumped into the working capacity of the water heater.

Advantages and disadvantages

This method of heating has several advantages:

- The room heats up quickly enough due to the passage of high temperature steam through radiators and pipes.

- The system has a fairly compact size.

- There is no risk of the coolant freezing in the pipes, which in the case of water heating often leads to a gust.

- The cost of materials necessary for arrangement is relatively small.

On the other hand, steam heating is not without disadvantages:

- Firstly, pipelines wear quickly enough under high pressure, because they need to be repaired and replaced much more often.

Note! Preventive maintenance of all connections should be carried out regularly. This is a question not only of your comfort, but also of your safety.

- Secondly, the strong heating of the coolant makes it difficult to precisely control the temperature through climate control systems.

- Thirdly, the pipes during the passage of steam make a rather loud sound. After a while, of course, you will stop noticing it, but in the first weeks this noise can be unpleasant.

- Finally, very hot pipes should be placed in such a way as to minimize the risk of contact with them. However, burns from accidental contact with heated metal will still be inevitable.

Installation recommendations

Element selection

If you plan to do the arrangement of the steam heating system with your own hands, then you need to select all the components of the system very carefully.

We draw attention to the following points:

- The steam boiler is a key element that largely determines the performance of all installed devices. For our purpose, a dual-circuit model powered by gas or electricity is best suited. The optimal limitation of steam temperature for a private house is 130 0WITH.

Note! To ensure constant heating of water in the tank, you can also purchase a solid-fuel device with automatic loading of pellets from a special bunker.

- Pipes for connecting all parts using either steel or copper. The second option is preferable because copper is not susceptible to corrosion, but in this case the project cost will increase significantly.

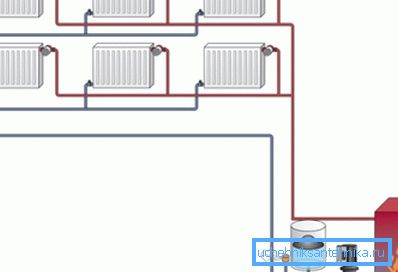

- It is possible to lay in the project both one-pipe, and the two-pipe scheme of laying of communications. A single pipe arrangement is cheaper, however, it is better to provide a separate pipeline for condensate drainage. So we will lower the noise level in the system, and it will be easier to regulate the heat flow.

- As for batteries, cast-iron radiators of the classical configuration, or steel panel devices, are perfect for our purpose.

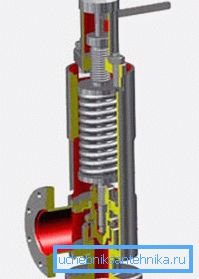

- For each heating circuit, we acquire an exhaust valve, which will automatically adjust the pressure in the system.

Nuances of assembly

Work on the arrangement begin with the installation of the boiler.

The instruction recommends to act as follows:

- The water heater is best installed in the basement or underground room - so the heated steam will rise through the pipes up due to natural forces. At the same time, the condensate will return to the tank by gravity.

- The room for the installation of the boiler sheathe non-combustible material. We pour a separate monolithic foundation under the boiler itself, which is designed to prevent its displacement during operation.

- At the outlet of the boiler must be mounted steam valve, which is used to adjust the flow of steam.

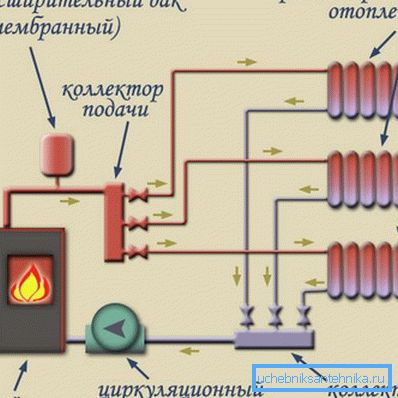

- Above the boiler is usually located a membrane expansion tank. Its main function is pressure equalization in the system.

- Having established a copper, we begin to lay pipes. We fix them on the supporting structures with the help of brackets.

- On the walls in the selected places we install heating batteries. Each radiator can be equipped with two taps, allowing, if necessary, to turn off the battery from the system, thus regulating the degree of heating of the air in the room.

- Carefully seal all connections, since the vapor pressure in the pipes will be quite high.

- Install exhaust valves responsible for the discharge of excess air.

Note! If an open circuit is used, then it is imperative that the pump be switched on to transfer the spent condensate from the tank to the boiler.

- We connect the boiler to the pipeline, fill it with water and perform a test run. During the tests, we monitor the readings of the pressure gauge, which records the level of pressure, and also monitor the appearance of leaks at the joints.

Conclusion

The above-described steam heating schemes (with one or two circuits, with an open or closed cycle) demonstrate maximum efficiency in private houses and cottages.

This design can be implemented independently, but if you do not have experience in carrying out heat engineering works, it is better to involve professionals in the solution of the problem, at least at the design stage. And in the nuances of performing individual operations, the video provided in the article will help to understand.