Steel heating radiators: how inexpensive, but qualitatively

Constructing a heating system of his own house or apartment, any owner wants the batteries chosen by him to be both powerful and beautiful and cheap. Today there is no need to look for a compromise solution. All these qualities have steel radiators.

In addition, they are as simple as possible to install, because they are the best choice for those who do house repairs with their own hands.

Varieties of products

Excellent technical characteristics and consumer properties of carbon steel do not require proof. This material is widely used for the manufacture of a huge number of different products: from toys to cars.

Radiators for heating systems were not left aside. Strength, lightness and flexibility of steel made it one of the popular materials for the production of batteries.

Currently there are two main types of heaters:

- panel type;

- welded from steel pipes.

Let us dwell on each in more detail.

Steel Sheet Heating Panels

Such a device for heating constructively consists of the following parts:

- Steel plate with coolant flow channels. She herself is two sheets of steel with pre-stamped grooves, which are welded to each other. In the radiators can be one, two or three pieces. Then they are interconnected by pipes.

- Heat exchanger. It is welded to the plate and serves to increase the contact area of the heated metal with the air in the room. This improves heat transfer and, consequently, battery performance.

Note! Plate and heat exchanger in the battery may not be alone. Models with several similar elements are being produced, thanks to which steel radiators heat the air not only due to the radiation of thermal energy, but also by means of convection.

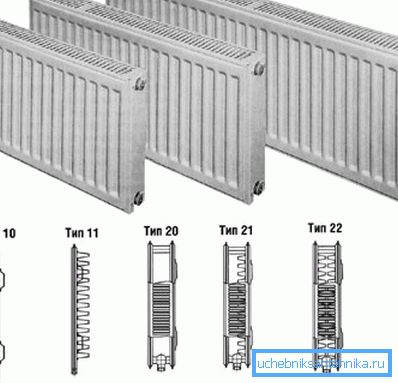

The following device models are distinguished:

- type 10 - one steel sheet, no heat exchanger;

- type 11 - one steel sheet, one ribbed surface to improve contact with air;

- type 20 - two steel sheets, the absence of a convector radiator;

- Type 21 - two steel sheets, one heat exchanger for convection;

- type 22 - two steel sheets with two finned radiators, which improve the efficiency of air exchange;

- type 30 - three rows of steel plates without fins between them;

- type 33 - three rows and three convection gratings.

Whatever it was, steel panel radiators, despite the number of layers, are quite narrow and do not require large space for mounting and massive brackets.

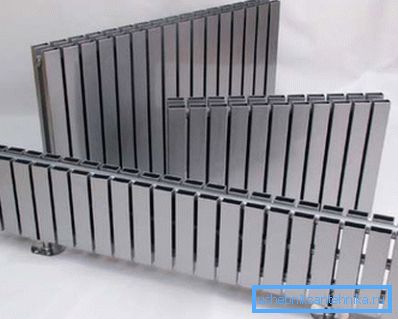

Steel tube heating batteries

Structurally, this steel radiator is a set of metal pipes (of various diameters and lengths), which are welded together. The described method of manufacturing is more laborious, therefore the price of the products in question is much higher (more than bimetallic batteries).

One of the common variants is welding one or several rows of vertical pipes, which are joined from above and below by horizontal collectors. But there are design solutions that can not only heat the house, but also serve as interior decoration.

Battery manufacturers

First of all, it should be noted that steel domestic heating radiators are not used very often.

The most common products of the following brands:

- Korado (country of origin - the Czech Republic);

- PURMO (Finland);

- Demrad (Turkey).

Tip! Turkish heating steel radiators, despite the assurances of manufacturers, do not differ in quality, since in their manufacture thin-gauge low-grade steel is used, and the protective layer of paint often peals. It is advisable to opt for more famous brands. As a last resort, we advise you to turn your attention to the Belarusian brand - Lidea - characterized by low cost and quite acceptable quality.

Technical characteristics of steel radiators

Having dealt with the design features and manufacturers, it's time to go on to discuss the technical characteristics of individual models, because they directly influence the choice of a particular type of product:

- Coolant pressure. Most radiator panels, this value is 6-10 atmospheres. This is due to the ductility of steel, therefore it is impossible to make more durable radiators for objective reasons. Tubular models withstand about 15 atmospheres. Without going into further discussion of technical nuances, it should be noted that the instruction for installing steel batteries prohibits their connection to heating networks with a centralized coolant supply circuit, since they simply will not withstand the water pressure.

- The quality of the circulating fluid. Radiators are insensitive to the chemical and physical composition of water, but very badly deteriorate from air that penetrates into the piping system. The slightest airlock leads to a violation of the uniformity of heating and causes rapid corrosion of steel.

Many manufacturers cover the internal surfaces of batteries with special protective compounds (for example, Corado radiators), but to date, an effective method of dealing with rust inside steel panels has not been invented.

It is for this reason that steel batteries are not installed in city apartments, because there the coolant is drained at the end of the heating period.

- Hot water temperature. Steel sheets can withstand temperatures not exceeding 120 degrees Celsius. Otherwise, the integrity of the battery manufacturer is not guaranteed.

- The distance between the pipes. Piping pipes to batteries can be organized in various ways: from the bottom or from the end. In the latter case, the distance between the incoming and outgoing pipe can be different - from 50 to 70 cm. This must be taken into account when laying pipelines (especially if they are embedded in the wall). As for the tubular models, it all depends on the variety you purchased. The distance range is extremely wide: from 12 cm to 3 meters.

- Geometric parameters. It directly depends on them how the radiator you purchase fits into the design of the room. In addition, the dimensions affect the weight, it must be considered when buying and installing brackets. The most common batteries of the following sizes:

- panel - length up to 3 meters, height 20-90 cm;

- tubular - length is unlimited, height is from 20 cm to 300 cm.

Tip! Before purchasing the latest type of batteries, check their depth. Multi-row radiators can be quite “thick”.

- Thickness of steel sheets. Despite the fact that this nuance few people take into account, it is very important. From this parameter directly depends on how durable will be the product you purchase. The thicker the steel used, the longer the heating radiator will serve you.

- Ergonomic. Here we are, above all, talking about the ease of installation. Inlets, as already mentioned, can be installed both on the side and on the bottom. The latter option is more aesthetic, but requires the laying of pipelines under the sub-floor, which is not always possible.

The installation procedure of the steel radiator

Installation of the device on the wall and its docking with pipelines will not cause difficulties even for a novice master. But pay special attention to the quality and accuracy of the operations. The slightest inaccuracy when installing the brackets can lead to imbalance, which will cause the deposition of minerals in the battery. And this will eventually cause a breakdown.

The procedure is as follows:

- All plugs are removed from the battery nozzles, threaded connections are cleaned of dust and debris, the battery is washed with water.

- Air vents, thermostats and valves are mounted on the designated places.

Note! To seal the joints, it is recommended to use tow or polymer tape, as well as silicone sealant, which allows you to achieve maximum watertightness of the joints.

- The old battery is removed (if necessary). Do not forget to drain the coolant from the heating system. If the threaded connections are not amenable, you can simply cut pieces of pipes with a grinder.

- Brackets are hung for the future panel. Before this, you need to carefully mark and drill, otherwise the battery will not take its place and will force you to mount the mount again. The brackets can be fixed with dowels or anchor bolts.

- Sgons are screwed onto steel pipes, and special couplings are soldered to the ends of the propylene pipes.

- Installation of the entire system. It is desirable to use torque wrenches that allow you to measure the force and firmly tighten the joint without disrupting the thread.

Then start the system.

This is done in this way:

- ready heating network is pressurized (for this purpose a special apparatus is used);

- pipelines are filled with coolant (it is necessary to perform this operation carefully to avoid pneumatic and water hammer, as well as to allow air to escape through pre-installed valves);

- the boiler starts up at minimum mode and only after checking the joints is the final adjustment of all parameters made).

Conclusion

Steel radiators are an inexpensive and effective way of arranging a heating network with an autonomous boiler. As for urban apartments with central heating, it is better to choose other solutions. For more information about our topic, you can learn from the video offered to your attention.