Steel panel radiators: the main features, the difference in

The start of production of panel radiators goes back to the end of the last century. And until now, these devices are well-deserved among consumers, taking pride of place in their homes. They are stamped in a special way, with the result that through channels are formed between the plates. Depending on a design, all steel panel radiators of heating differ in technical parameters, a form, the sizes, and also type of supply of the heat carrier.

The classification of this type of radiator is made according to the type indicating the number of panels and the presence or absence of fins. Since the production process is less labor intensive, their price is slightly lower than that of aluminum and bimetal heaters.

In the construction market they can be found in a wide range, so first you need to figure out what technical characteristics of steel panel radiators deserve attention, making a comprehensive assessment.

Key Features

- Supply of heat carrier to any radiators made of metal can be carried out both from the bottom and from the side.

- The production process of these devices consists in welding between themselves sheets of pre-rolled metal, whose thickness is 1.25 mm.

- The design includes panels and convectors (fins). Moreover, both can be present either in one copy or in several.

The difference in type

In everyday life, radiators of three types are most popular: 11, 22, and 33. Therefore, we will understand below what these symbols mean:

| eleven | Consists of one panel, on the back side of which the fins are located. Such a radiator is not protected by a casing. |

| 22 | The design of the heating device includes 2 rows of panels, to the inner side of which 2 convectors or fins are welded. Protected by cover. |

| 33 | It implies equipping the model with three rows of panels and the same number of convectors. To protect the device used casing. |

Digital indicators such as radiators talk about their technical parameters. In this case, the higher the type, the more efficiently the device operates. For example, type 33 may have a smaller size than 11, but its heat transfer will be much higher, which is explained by the presence of additional fins and, consequently, greater thickness.

Tip: in some cases it is recommended to install several radiators of type 11 rather than one type 33, for example, on flight of stairs where their strong protrusion is undesirable.

All steel radiators differ in the type of coolant supply, which can be both the bottom and the side. In spite of the fact that at the lower feed the appearance of the heater is more attractive, it is not very convenient to maintain it. It is much more practical to use a device with a lateral supply of coolant.

Advantages and disadvantages of devices

- The main disadvantage of steel radiators is that their operation is possible only if the pressure in the heating system does not exceed 10 atmospheres.. This completely eliminates the possibility of their connection to a centralized heating system. But you can find and models, the technical characteristics of which provide for their operation at a pressure in the system of 30-40 atmospheres. The price of such devices, of course, much higher. However, you can install such radiators in a city apartment, if you put a pressure reducer on them.

- However, the problems do not end there.. Given the contamination of the coolant supplied to the batteries connected to the central heating, it will be necessary to filter it during the operation of steel radiators.

In spite of everything, steel radiators are deservedly in demand among the owners of private houses and cottages:

- they are often used to heat summer houses;

- it should be noted that the cost of radiators with lateral coolant flow is less than those with heat transfer medium from below;

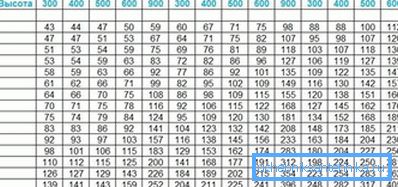

- Many models are available to consumers, distinguished by size, including height and width, as well as the distance between the axes, which allows them to be selected for each room individually. For example, several radiators of different types and heights can be installed in the same room;

- An important positive quality of steel heating devices is that the heating of the rooms is carried out by the convective method - cold air enters the radiator from the bottom, which, passing through the fins, heats up and comes out from the top already hot. Considering that the maximum length of such devices can reach 3 m, they allow you to create an effective thermal curtain even under the widest window.

The service life of steel radiators is long enough and can reach up to 10 years. The manufacturer applies a passport to each product, which guarantees high quality of the goods.

If necessary, such radiators can be made to order. In this case, the consumer has the opportunity to get the required number of heaters, different in size, type and technical parameters.

Steel convectors require periodic cleaning.

However, unlike other heating devices, the instruction for their maintenance is quite simple:

- remove the protective cover, which performs rather a decorative function;

- collect dust inside with a regular vacuum cleaner;

- clean the panels with a damp cloth.

Choice - what to pay attention

Since steel is susceptible to corrosion, all parts of panel radiators, both external and internal, are covered with a protective compound. Ceramic enamels and paints, titanium or graphite, are used as coatings. If the quality of the composition is low, over time it can change color.

Therefore, when buying a radiator, first of all:

- should pay attention to the quality of its color;

- Please note that there should not be any spots or traces of uneven coating on the surface of the device.

Otherwise, all these shortcomings can lead to corrosion of the metal and its further destruction.

You should also make sure that the radiator housing does not contain various types of dents and scratches. Do not forget that thin metal sheets are susceptible to any damage.

Taking into account the fact that they are welded together during the production process, the presence of any damage over time will not only cause the formation of rust, but also lead to leakage.

Tip: even if the packaging of the device is damaged, you should not buy it.

Conclusion

Light and easy-to-use steel panel radiators are best used in individual heating systems, since the limiting heat carrier pressure should not (for the vast majority of models) exceed 10 bar.

When buying a device, make sure that its packaging is intact, the coating is uniform, and there are no dents or scratches on the product itself. It is most convenient to use the device with a side pipeline connection. The video in this article will allow you to find additional information on the above topic.