Technical characteristics of aluminum radiators: types of

The characteristics of aluminum radiators are very high, and the best evidence of this is the great popularity of this type of product among buyers. But in order for the products to work as efficiently as possible and serve as long as possible, it is necessary to comply with a number of conditions, as well as competent calculation of the system and its high-quality installation. In this review, we consider all the characteristic features of products made of aluminum.

Main types of products

All the options on the market differ primarily in the mode of production, all the technical characteristics of aluminum radiators largely depend on this, so you need to start the consideration with this factor:

| Casting method | Regarding this method, you can tell the following: sections differ in special forms of silumin, this is the name of aluminum-silicon alloy, which is characterized by increased strength. This option can withstand pressure from 6 to 16 atmospheres, an increase in strength in this embodiment is realized by increasing the wall thickness. |

| Extrusion | This option involves the manufacture of individual elements, which are subsequently connected to each other by pressing under high pressure, to increase the strength of the collector can be cast from silumin. This is the easiest and most inexpensive method of production, so it is the most common |

| Anodizing | Products of this type are made of the best quality raw materials and processed by anodizing, which changes the surface structure of the material and makes it much stronger and more resistant to corrosion processes. This is the most reliable option that can withstand pressure up to 50 atmospheres, but its price is much higher than more budget options. |

Note! When purchasing, always specify which method is used to make the products, as this is very important and the cost changes significantly.

Overview of the main features of radiators

If you decide to do the installation yourself, then you will have to not only install, but also acquire all the necessary elements, so you need to sort out this issue as best as possible in order to avoid mistakes and mistakes.

Pros and cons of aluminum products

First, consider the advantages and disadvantages of the option we are considering.

Let's start with the advantages:

- The capacity of the aluminum radiator is small, so the heating of the room occurs in a very short time. With regard to thermal conductivity, this group of products is in the leading positions, so you can save on energy, because the efficiency coefficient with proper installation will be very high.

- Aluminum radiators according to GOST 31311-2005 must meet a number of criteria, so if you choose products from a domestic manufacturer, the best evidence of quality will be compliance with this regulatory act, such products can be purchased without any concerns.

- A small mass of products greatly simplifies their transportation and installation, so aluminum radiators are much easier to install than cast iron, which is very heavy.

- The installation of thermostatic regulators allows not only to precisely adjust the temperature in the room, but also to reduce energy costs in the period when there is no one at home, you can adjust all the settings by time and day of the week.

There are products and their disadvantages:

- When the quality of the coolant inside is low, corrosion processes begin to develop.

- The presence of impurities causes damage to the internal cavities.

- Connection with copper elements is strictly prohibited.

- The service life with adverse effects is reduced significantly.

Specifications

There are several important criteria:

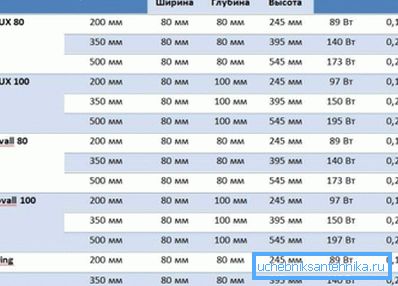

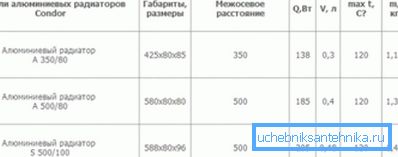

- Dimensions of aluminum radiators are determined by the center distance, The most common options are 350 and 500 mm, but if you wish, you can find other solutions, most often the manufacturer’s size range starts at 200 mm and ends at 800-900 mm. As for the width and depth, they are always the same, the width is 80 mm, and the depth depending on the manufacturer can vary between 80-85 mm.

- Operating pressure shows for which indicators the system will work normally and for which parameters it is initially provided. Most often, this figure ranges from 10 to 15 bar, but in anodized versions can be much more.

- Opressovoe pressure shows the maximum loads the structure can withstand; this value is important if radiators are used in apartment buildings, pressure testing is done there, that is, water supply under pressure, which is one and a half times higher than the standard, is necessary to check the tightness of the system.

- Heat transfer varies depending on the brand and size and can be from 100 to 200 watts, more detailed information you will give instructions, which must necessarily be attached to each product.

Often there is a question, how many aluminum radiators are needed per 1m2, in fact, there are no such indicators and cannot be, since the calculation is made individually for each room.

In more detail this issue was covered in another review on our website, here we only mention the main recommendations:

- Calculation of aluminum radiators is better to produce not per square meter, but per cubic meter of volume, so the indicators will be much more accurate.

- Do not forget to take into account the heat loss of the room, which depends on the type of building, its location, the quality of insulation, the presence of windows and exterior walls, etc.

- It is also important to remember that the thermal power prescribed in the documentation is designed for a specific coolant temperature, if this figure is usually lower, then the radiator power decreases in accordance with the difference.

- The calculation of aluminum radiators can be made using special programs, in which you just need to enter all the data, and they will give the result.

Disassembly and assembly of sections are made using a special tool, the key size for aluminum radiators depends on the size of the nipple, usually it is 32 mm.

Tip! If the key is not at hand, you can make it yourself by welding the plate of the desired width on one side and the transverse handle on the other.

Conclusion

Aluminum products are ideal for private building, in high-rise buildings it’s better not to use them. The video in this article will tell you about some of the above nuances in more detail and will allow you to understand them even better.