Temperature graph of the heating system: familiar with the

What laws are subject to changes in the temperature of the coolant in central heating systems? What is it - the temperature schedule of the heating system 95-70? How to bring the heating parameters in line with the schedule? Let's try to answer these questions.

What it is

Let's start with a couple of abstract theses.

- With changing weather conditions, the heat loss of any building changes after them.. In freezing in order to maintain a constant temperature in the apartment, much more thermal energy is required than in warm weather.

Specify: the cost of heat is determined not by the absolute value of the air temperature on the street, but by the delta between the street and the interior. So, at + 25C in the apartment and -20 in the yard, the heat costs will be exactly the same as at +18 and -27, respectively.

- The heat flow from the heater at a constant temperature of the coolant will also be constant. A drop in room temperature will slightly increase it (again, by increasing the delta between the heating medium and the air in the room); However, this increase will be categorically insufficient to compensate for the increased heat loss through the building envelope. Just because the lower threshold of temperature in the apartment is limited by current SNiP to 18-22 degrees.

The obvious solution to the problem of increasing losses is to increase the temperature of the coolant.

Obviously, its growth should be proportional to the decrease in outdoor temperature: the colder it is outside the window, the greater the heat loss will have to be compensated. Which, in fact, brings us to the idea of creating a specific table for matching both values.

So, the graph of the temperature of the heating system is a description of the dependence of the temperature of the supply and return pipelines on the current weather outside.

How things are arranged

There are two different types of charts:

- For heat networks.

- For in-house heating system.

To clarify the difference between these concepts, it is probably worth starting with a brief insight into how central heating works.

CHP - heat networks

The function of this bundle is to heat the coolant and deliver it to the end user. The length of heating mains is usually measured in kilometers, the total surface area - in thousands and thousands of square meters. Despite the measures for thermal insulation of pipes, heat loss is inevitable: having passed the way from the CHP or boiler house to the border of the house, the process water will have time to partially cool.

Hence the conclusion: in order for it to reach the consumer, while maintaining an acceptable temperature, the supply of the heating main at the exit from the CHP plant should be as hot as possible. The limiting factor is the boiling point; however, with increasing pressure, it shifts towards higher temperatures:

| Pressure, atmosphere | Boiling point, degrees Celsius |

| one | 100 |

| 1.5 | 110 |

| 2 | 119 |

| 2.5 | 127 |

| 3 | 132 |

| four | 142 |

| five | 151 |

| 6 | 158 |

| 7 | 164 |

| eight | 169 |

Typical pressure in the supply pipe of the heating main is 7-8 atmospheres. Such a value, even taking into account pressure losses during transportation, allows the heating system to be started up in houses up to 16 floors high without additional pumps. However, it is safe for highways, risers and connections, hose mixers and other elements of heating and hot water systems.

With some margin, the upper limit of the flow temperature is assumed to be 150 degrees. The most typical temperature graphs of heating for heating mains lie in the range of 150/70 - 105/70 (flow and return route temperatures).

House

There are a number of additional limiting factors in the house heating system.

- The maximum temperature of the heat carrier in it cannot exceed 95 С for two-pipe and 105 С for one-pipe heating system of the building.

By the way: in preschool educational institutions the restriction is much more severe - 37 C. The price for reducing the supply temperature is an increase in the number of radiator sections: in the northern regions of the country, the premises of groups in kindergartens are literally belted by them.

- Delta temperatures between the supply and return pipelines for obvious reasons should be as small as possible. - otherwise the temperature of the batteries in the building will vary greatly. This implies fast circulation of the coolant. However, too fast circulation through the house heating system will lead to the fact that the return water will return to the highway with excessive heat, which is unacceptable due to a number of technical limitations in CHP operation.

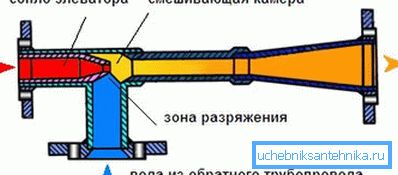

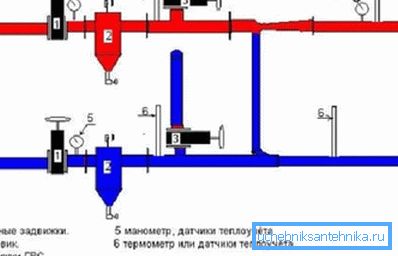

The problem is solved by installing one or more elevator nodes in each house, in which a return line is mixed with the water stream from the supply pipe. The resulting mixture, in fact, ensures the rapid circulation of a large volume of coolant without overheating the return pipeline route.

For in-house networks, a separate temperature schedule is set based on the elevator operation scheme. For two-pipe circuits, a typical temperature schedule for heating is 95-70, for one-pipe (which, however, is a rarity in apartment buildings) - 105-70.

Climatic zones

The main factor that determines the scheduling algorithm is the estimated winter temperature. The coolant temperature table should be compiled in such a way that the maximum values (95/70 and 105/70) at the peak of the frost provide the corresponding SNiP temperature in the residential premises.

Let us give an example of the intra-house schedule for the following conditions:

- Heating devices - radiators with coolant flow from bottom to top.

- Heating - two-pipe, with stand-up piping.

- Design temperature of outdoor air is -15 C.

| Outdoor temperature, C | Giving, With | Return, With |

| +ten | thirty | 25 |

| +five | 44 | 37 |

| 0 | 57 | 46 |

| -five | 70 | 54 |

| -ten | 83 | 62 |

| -15 | 95 | 70 |

Nuance: when determining the parameters of the route and the in-house heating system, the average daily temperature is taken. If at night it will be -15, and in the daytime -5, -10C appears as the outside temperature.

And here are some values of estimated winter temperatures for Russian cities.

| City | Design temperature, С |

| Arkhangelsk | -18 |

| Belgorod | -13 |

| Volgograd | -17 |

| Verkhoyansk | -53 |

| Irkutsk | -26 |

| Krasnodar | -7 |

| Moscow | -15 |

| Novosibirsk | -24 |

| Rostov-on-Don | -eleven |

| Sochi | +one |

| Tyumen | -22 |

| Khabarovsk | -27 |

| Yakutsk | -48 |

Adjustment

If the management of the CHP and heat networks is responsible for the parameters of the route, then the responsibility for the parameters of the house network is assigned to the residents. A very typical situation is when with complaints of residents about the cold in the apartments, measurements show deviations from the schedule in the downside. Slightly less often it happens that the measurements in the wells of the heat engines show an elevated return temperature from the house.

How to bring the heating parameters in accordance with the schedule with your own hands?

Nozzle drilling

When the temperature of the mixture and return temperature is too low, the obvious solution is to increase the diameter of the elevator nozzle. How it's done?

Instructions - at the service of the reader.

- Overlap all valves or valves in the elevator assembly (inlet, house and DHW).

- The elevator is being dismantled.

- The nozzle is removed and reamed by 0.5-1 mm.

- The elevator is assembled and started with air bleeding in the reverse order.

Tip: instead of paronitovye gaskets on the flanges can be put rubber, cut to the size of the flange of the car chamber.

Muffling choke

In a critical situation (strong cold and freezing apartments) the nozzle can be completely removed. So that the aspirator does not become a bridge, it is jammed with a pancake of steel sheet with a thickness of at least a millimeter.

Warning: this is an emergency measure that is used in extreme cases, since in this case the temperature of radiators in the house can reach 120-130 degrees.

Differential adjustment

At elevated temperatures as a temporary measure until the end of the heating season, it is practiced to adjust the differential on the elevator with a valve.

- DHW switches to supply line.

- A pressure gauge is installed on the return pipe.

- The inlet valve on the return pipeline closes completely and then gradually opens with pressure control on the pressure gauge. If you just cover the valve, the drawdown of the cheeks on the rod can stop and thaw the contour. The drop is reduced by increasing the pressure at the return flow of 0.2 atmosphere per day with daily temperature control.

Conclusion

We recall once again: the last two recommendations can be applied only in critical situations as temporary measures. As always, the video attached to the article will provide the reader with additional subject information. Successes!