The register of smooth pipes: what should be considered when

When heating premises with a large volume: warehouses, workshops, hangars, public organizations, heating registers made of smooth pipes are most effective. They have a great length. Therefore, they create not a local, but a volumetric source of heat.

In residential buildings, registers are used in toilets and bathrooms, in which the installation of radiators is unprofitable, because of their complex surface.

Instrument characteristics

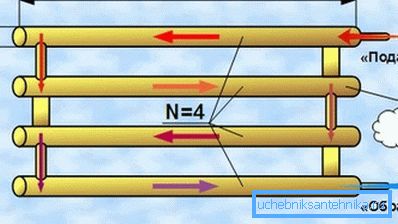

- The device consists of several pipes, which are connected by bridges and are located against the wall. (See also the article How to increase the heat output of a heating pipe: features.)

- Heat carrier - steam, antifreeze, water, oil, enters the register on one side and is discharged on the other.

Note! Between elements there should be gaps equal to their cross section + 50 mm. This eliminates their mutual irradiation, and the heat transfer of the registers from smooth pipes increases.

- The diameter of the elements can be from 25 mm to 400.

- The maximum allowable pressure in the devices should be 1 MPa.

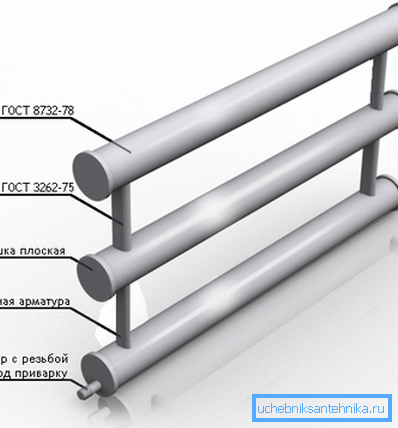

- The most common material of registers is electrowelded pipes made of carbon, stainless or low-alloyed steel. There are also home-made devices made of cast-iron elements.

Note! Aluminum products have a greater heat transfer than steel. However, they are not durable. The quality of the coolant greatly affects their service life.

- The nozzles of the device are mounted in three ways: threaded, flanged and welded.

Device Classification

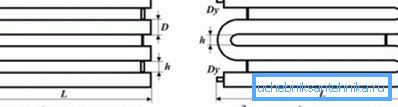

The device can have two configurations.

- Sectional analogues consist of 2/4 elements, the ends of which are closed with plugs, elliptical or flat. The coolant flows through the pipe to one side of the section, and leaves the other. This ensures maximum heat transfer. The device can be equipped with a nipple and an air tap is connected to it.

- In serpentine (S-shaped) devices, the elements are connected by arcs, the diameter of which is sectional. This form gives the device greater efficiency, because the area for heat exchange increases. The heater (it can be used for a smooth rigid PVC pipe) does not have areas with a narrowing of the diameter, this lowers the hydraulic pressure.

By design, there are 5 types of devices:

- two-row P-shaped device;

- three-row S-shaped device;

- sectional analogue with jumpers of two or more rows;

- two-row U-shaped device with a jumper;

- double row sectional analog having a jumper.

Register value

- High level of heat transfer allows you to effectively heat large areas with relatively small dimensions of the device. (See also the article Connecting to sewage: features.)

- Building and installing the register is relatively simple.. The drawing is not needed for it. To make the device with your own hands, it is enough to have a welding machine and a grinding machine with a cutting wheel.

- Device can withstand high pressure (about 1 MPa) and is resistant to its jumps (hydraulic shocks).

- The instruction allows the use as a coolant in the registers: water, oil, antifreeze, steam.

- Due to its length, the device evenly heats the room..

- Price registers available, they do not need additional fittings for installation.

Required calculations

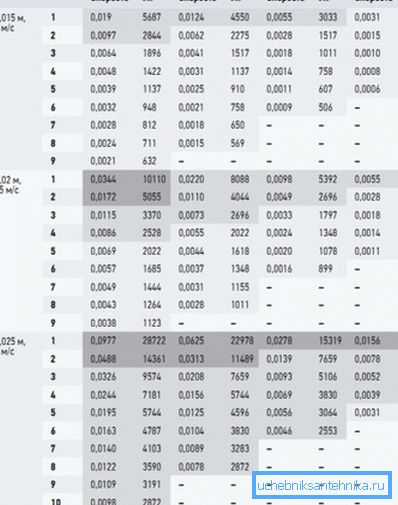

Head losses throughout the length of the coolant flow substantially depend on the degree of roughness of the pipe walls. Their surface is always different from absolutely smooth and has irregularities and protrusions.

On this basis, when calculating the register, it should be noted that specialists distinguish between hydraulically smooth and rough pipes.

Rough and smooth pipes

The size and shape of the protrusions are dependent on the material of the products (the smoothest is the HDPE pipe) and its degree of processing. Important and operating conditions. In its course, the material may corrode, solid particles contained in the coolant, etc. may settle on the pipe walls.

The walls of all pipes are covered with micro-elevations, having an average height of roughness protrusions. Is it denoted by a letter?

Based on how the dimensions of the roughness hillocks correlate with the thickness of the laminar film (is it denoted?), The pipes (with turbulent motion) are divided into 3 types.

- Hydraulically smooth pipes are the highest quality products.. If the height of the micro-elevations is less than the thickness of the laminar film, then the surface roughness does not affect the movement of the coolant. Consequently, the pressure loss is not dependent on the roughness of the pipe. The walls of the products in this case belong to the hydraulically smooth.

- If the height of the protrusions is greater than the thickness of the laminar film, the pressure loss is dependent on the internal relief of the products.. Such pipes belong to hydraulically rough.

- When the average height of the tubercles is approximately equal to the level of the thickness of the laminar film, the pipe walls belong to the transition category of resistance.

The thickness of the laminar film is calculated by the formula:

??30 • d / Rev ?, where:

- d is the internal diameter of the pipe;

- Re is the Reynolds number (average coolant flow rate);

- ? - the value of the coefficient of hydraulic resistance.

To calculate the registers of smooth pipes for heating, you can use an approximate amount of roughness of the roughness for the walls. Values are presented in the table.

| Pipe material | ?, in millimeters |

| new seamless steel | 0.02 / 0.05 |

| same but used | 0.15 / 0.3 |

| new welded steel | 0.04 / 0.1 |

| new cast iron | 0.25 / 1 |

| used welded steel and cast iron | 0.8 / 1.5 |

| new asbestos cement | 0.05 / 0.1 |

| Same but used | 0.6 |

| reinforced concrete and concrete | 0.3 / 0.8 |

One of the lowest indicators has a smooth PVC pipe - 0.01 / 0.02 mm.

Power calculation

Adaptation can be done on their own. Before this, it is necessary to calculate the register of smooth pipes using the formula:

Q =? • dn • l • k • (tg? To) • (1 ?? of).

The letters in it mean:

- ?= 3.14;

- dн - external diameter of pipes, in meters;

- l is the length of the section or section, in meters;

- k - heat transfer coefficient (11.63 W / m2 • ° С);

- tg is the temperature of the coolant;

- to - air temperature in the room;

- ?of - the coefficient of heat saving by the insulating material, when the register has it, the figure is 0.6 / 0.8, if it is not there, the coefficient is zero.

For example, take the following source data:

- section length - 5 m;

- diameter of pipes - 159 mm;

- water temperature - 80 °;

- the temperature in the room is 23 °.

Substituting the numbers in the formula, we derive a total of 1655 watts. The value indicates the thermal power of a horizontal single-row device. When there are several sections, use a reduction factor for each of them. It is 0.9.

Conclusion

When making the register yourself, be sure to pay attention to the type of pipes for it in terms of smoothness. This value will affect the flow loss of the coolant, and hence the efficiency of the device.

The video in this article will help you understand its topic.