Three-way valve for heating: purpose, device, features of

For installation of heating systems, various shut-off and control valves are used, and for successful assembly of plumbing equipment with your own hands it is necessary to understand it. We want to consider one of the most functional types of such valves - a three-way valve.

Multiport Cranes

Device

The three-way valve is a T-shaped branching of pipes with a locking and adjusting mechanism. The device has two inputs and one output, and if you turn it on the contrary - one input and two outputs.

Input inputs are denoted by letters A and B, and output - AB.

The locking mechanism has three positions (three turns):

- In the first position, water enters the entrance A and flows out of the exit AB, while the entrance B is completely blocked;

- In the second position, the water moves from the entrance B to the exit AB, and the entrance A is completely blocked;

- In the third position, the water flows into both inlets A and B, and at the outlet AB we get a mixture of two streams.

Note! The listed provisions are fair for adjusting models. Products intended only for switching flows have no third position.

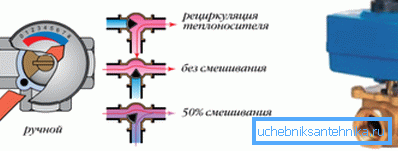

The locking mechanism can be arranged in various ways:

- Sharovy. Designed to switch threads by overlapping one of the channels. For adjustment is bad;

- Rotary. It is used for adjustment, as it allows to open and close the channel smoothly;

- Saddle. It can have both a locking and adjusting design.

The mechanism is controlled either manually using a handle (handwheel) or by means of an electric drive. Equipped with servos, products can be built into systems with automatic control.

Note! Despite such an important functionality and a certain indispensability, the design of the device is quite simple, and therefore its price is low.

Purpose and functions

The three-way valve can perform three functions:

- Mixing coolant flow. It is used when it is necessary to mix the return flow into the feed to lower the flow temperature to the low-temperature circuits or to adjust the power of the radiators without changing the operation of the boiler;

- Splitting one stream into two channels. It is used to drain the heated coolant to the hot water system or storage tank, boiler, etc .;

- Switching the direction of the coolant. It is used when several devices work together in the same system, as well as to switch the circuit to recirculation mode.

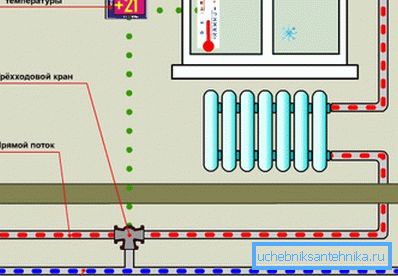

Consider one of the most common cases: the heating boiler is connected to radiator wiring and a heated floor collector. As is known, the heat carrier for radiators has a temperature of about 70 - 95 degrees, whereas the heat carrier for a system of warm floors should not heat up above 40 - 50 degrees.

If we lower the temperature of the coolant, then the radiators will not work normally, and the house will become cold. If we serve boiling water on the warm floor, it will be unpleasant to walk on the floor. What do we do?

This is where the three-way valve comes in handy. The return pipeline is connected with the supply to the collector of a warm floor bypass with a three-way valve, which is set to the mixing mode.

As a result, a cold stream from the return flow is mixed into the hot water stream, and the temperature of the resulting jet is averaged to the 40 to 50 degrees we need. If desired, by adjusting the position of the flap, you can raise or lower the temperature in the contour of the floor.

Another example is the connection of the radiator via bypass in the same way. When the faucet is in the mixing position, the temperature of the radiator becomes lower than the temperature of the coolant flowing from the boiler, while the rest of the devices get less cooled water.

If we switch the handle and shut off the bypass, then the radiator will work at full capacity. If we need to turn off the device, we simply put the valve in the mode of shut off return and open bypass, and shut off the stop valve at the radiator inlet. After that, the coolant circulates around this battery.

Note! It is possible to use a four-way valve, which does not require a bypass.

Finally, the instruction allows the use of a multi-way valve in multi-circuit systems with parallel operating boilers, a boiler and an indirect heating boiler, with water supply for heating and hot water supply. The devices allow to separate the flows and regulate their temperature, ensuring the joint operation of several units and circuits.

Note! If a valve with a servo drive is connected to a thermostat, then when the room temperature drops, the controller will give a command to the engine, and it will close the bypass. When the desired value is reached, the device will go back to blending mode.

Conclusion

Three-way valves allow mixing, separation and switching of flow directions in the circuits of heating systems. The video will help you visually verify their effectiveness and functionality.