Two-pipe heating system: options for implementation and

How is the two-pipe heating system of a private house or an apartment building? By what signs can similar systems be classified? What problems may arise in the implementation of this scheme and how to solve them? Let's figure it out.

What it is

Let's start with a description of the general principles of the heating system.

Heating of heating devices is provided by the circulation of coolant through them (process water, antifreeze, ethylene glycol, etc.). For circulation, a differential created between the input and output of the device is necessary.

This differential can be provided in several ways:

- By connecting through the elevator unit to the heating main, where the pressure difference between 2 and 3 kgf / cm2 is maintained between the supply and return lines.

Nuance: after the elevator, the difference between the mixture and the return flow is much less - 0.2 - 0.3 kgf / cm2. Exceeding this value would make the circulation excessively fast. The consequences are noise in the pipes and excessive temperature of the return pipeline.

- The circulation pump.

- The difference in the density of hot and cold coolant in the so-called gravity (gravity) systems.

It is obvious that in all cases it is necessary to ensure that each heater is connected to the common system with two connections. This can be done in several fundamentally different ways.

| Scheme | Short description |

| Single pipe | Heating devices are connected to a common ring circuit |

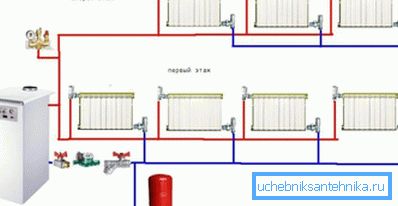

| Twin tube | Heating devices are connected between the supply and return pipelines running along the entire perimeter of the heated premises. |

| Collector | Each heater is equipped with its own pair of connections connected to a common collector. |

It is curious: in multi-apartment buildings, mixed radiator connection schemes prevail. The presence of dedicated supply and return filling of the heating system makes a two-pipe; at the same time, within the riser, the batteries are often combined in series.

Classification

The two-pipe heating system, in turn, can be classified according to several additional features.

Orientation

The vertical scheme is applied only in high-rise buildings. Each radiator is a jumper between the supply and return risers passing nearby.

The horizontal scheme can be used both in apartment buildings (the example of two bottling was mentioned in the paragraph above) and in the cottages.

Passing and dead ends

In the following scheme, the coolant in the flow and return flow moves along the ring in one direction; dead-end - in opposite directions. The dead-end scheme is in demand where doorways or panoramic windows make it difficult to install a full ring of pipes.

Lower and upper bottling

Until about the 70s of the last century, houses with upper bottling prevailed on the territory of the USSR: from the elevator assembly, the supply pipeline went up to the attic; from there the coolant through the risers entered the return line located in the basement.

The use of such a scheme has several practical implications:

- Attic willy-nilly was made heated and had dimensions sufficient for maintenance and repair of valves.

- Each heating riser during repairs had to be turned off at two points - in the basement and in the attic.

- When you start a dropped system (both the whole and individual risers), you had to bleed air out of it. For this purpose, the feed dispenser was mounted with a slight slope, and at its upper point an expansion tank with a dumpbox was installed. Accordingly, the launch of the house was accompanied by a visit to the attic.

By the way: in some cases, the dumper was still brought to the basement through all the floors. With a small discharge section, the air was forced out through it at the water flow front.

With the advent of flat roofs and the development of panel house building, the upper bottling was almost crowded out by the lower ones: both the supply and return flown to the basement. Risers began to connect in pairs in the apartments of the upper floor. After a reset, each one needs to remove the airlock; for this purpose, Mayevsky taps or ordinary valves are mounted in the upper floor apartments.

Please note: the scheme with lower bottling is more vulnerable to accidents during the cold season. Air discharge (especially in the absence of access to all air ducts) takes a long time; at low temperatures, it is not uncommon for some of the risers to freeze.

Merits

What, in fact, good 2 x pipe heating system?

Its main advantage is that it allows for a more or less constant temperature of heating devices throughout the building.

With a single pipe heating system, the battery connections at the beginning of the single filling ring will have a flow temperature (typically 70-75 ° C). at the end - the temperature of the return (50 C). Here, each radiator will receive coolant with a temperature slightly different from that provided by the supply boiler or the elevator assembly after the mixing unit (elevator).

In addition, in the case of a large house with a solid number of batteries, a 2-pipe heating system is simply not alternative: no single-tube ring configuration will cover all the rooms of an 80-apartment building.

Warning objections: yes, the collector scheme can more than replace the two-pipe one. However, the price of its implementation will be ten times higher due to the enormous consumption of pipes; in addition, a large total length of the connections will mean huge non-target heat loss.

Problems

Without them, too, not done.

Costs

Obviously, with an equal diameter, two pipes will always be more expensive than one. With a small area of a heated building, the obtained benefits will not compensate for this difference: it is easier to compensate for the temperature variation by increasing the number of radiator sections at the end of a single pipe ring.

Balancing

Two-pipe heating system of the cottage needs to be balanced.

What it is?

To begin, let us outline the essence of the problem.

Imagine that two pipes go from the heating boiler into the house. In the first, water flows to the radiators, in the second, it returns. In addition, each radiator is a jumper between these pipes.

What is the problem? Yes, the fact that each heating device will extinguish the difference between the flow and return flow. If on the first battery it will be equal, say, 0.2 kgf / cm2, then on the second - already 1.75, on the third - 1.5, and so on.

As a result, we get a very ugly picture:

- A stable battery temperature will not be discussed. The smaller the differential, the slower the circulation, the lower the temperature of the coolant reaching the radiator.

- What is worse, in extreme cold, the cooling of end batteries can lead to the formation of ice plugs with a complete stop of circulation and the inevitable defrosting of the heating pipes.

Instructions for balancing the heating system of the cottage do it yourself:

- Each radiator is supplied with a throttle on one of the connections (preferably on the return pipe).

- Coolant flow through the first heaters from the boiler or elevator is limited until their temperature equals the latter.

Useful: more convenient to use functional analogue of the throttle - thermostatic head. It allows you to set not the flow of water through it, but the target temperature.

A reasonable question: how does the two-pipe scheme work in an apartment building? There, battery choking is not practiced, but the temperature variation between them is relatively small.

The function of the throttle there is a variable diameter pipes. We give typical values for a ten-story house built in the years 80-90.

| Plot heating system | DU, mm |

| Lead to radiator or convector | 20 |

| Riser | 25 |

| Bottling at the end section | 32 - 40 |

| Bottling at the elevator | 40 - 50 |

Each section transition limits the coolant flow; taking into account the deliberately inflated throughput of bottling this is enough for the operation of the circuit in the normal mode.

Useful stuff

- When balancing with throttles, the time gap between changing the throttling mode and stabilizing the temperature of heating devices reaches 6 to 8 hours.

- For a cottage with an area of up to 100 m2 with forced circulation of the coolant in a two-pipe system, a reasonable minimum of the filling section is DU2, up to 200 m2 - DU25.

- In the gravitational system, bottling cannot be made thinner than DU32 when using polymer pipes and DU40 - steel. In addition, gravity flow systems are used on an area of no more than 100 m2: in a large-sized room, the hydraulic resistance of a long circuit simply will not provide the minimum required circulation rate.

Conclusion

We hope that the material at the disposal of the reader will help him in the design, construction or repair of heating systems. To learn more about how the two-pipe heating system works, the video in this article will help. Successes!