Types of bimetallic radiators. varieties of designs. which

It so happened that for most of our great power, the heating season lasts at least six months, so the people's interest in the quality of heating devices is far from idle. Cast iron and steel have been used for more than 100 years and everything is known about them, but what are the advantages and disadvantages of bimetallic heating radiators that appeared relatively recently, people still do not fully know. We have tried to systematize several points of view and present them to your attention.

Types of designs

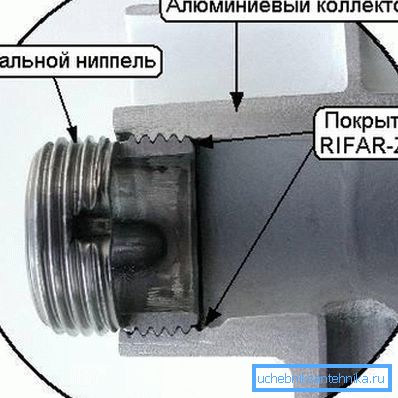

As the name implies, bimetal is a compound of two different metals. Most often it is a combination of steel and aluminum, although models are also produced where copper is combined with aluminum.

As a rule, it is a solid-cast or monolithic bimetallic radiator. The price of such copper-aluminum panels is the highest, but their heat transfer is several times higher than the characteristics of steel counterparts.

In addition to the usual carbon steel, batteries are available, in which the core is made of stainless steel. They are intended for systems where the coolant has an elevated pH level, as well as an unstable or high operating pressure. They are not much cheaper than copper. Stainless steel is good for high-rise buildings (more than 16 floors) and lovers of a serious safety margin.

Often, when people talk about such structures, they mean carbon steel and aluminum tandem.

But here it is not so simple, there is a so-called full bimetallic radiator and a partial, or pseudo bimetal.

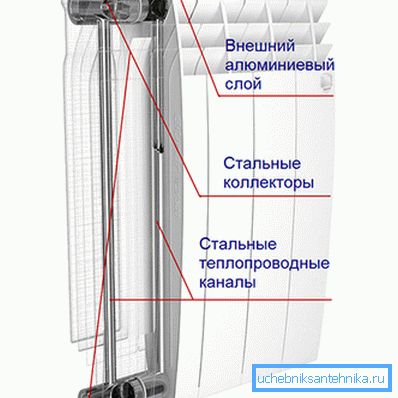

- The expression full bimetallic radiator, says that in such a battery has a solid steel core. The coolant in this case is not in any way in contact with the aluminum shell. In some sources, such models may be referred to as “enhanced”;

- The device is a bimetallic radiator with a steel core, provides for the installation of steel tubes only in the vertical channels of the structure. Thicker and wider horizontal channels in such batteries are made of aluminum.

Important: full and partially steel structures are available with both one and two vertical channels. The second option has a greater depth, but differs in improved heat transfer. Plus, not least, the probability of clogging both tubes at once is negligible.

Which option is better

- In urban skyscrapers, one of the greatest dangers is high pressure. Here the advantages of bimetallic radiators with a solid steel core are obvious. Working pressure in high-rise buildings often amounts to 6–9 atmospheres, which fits well with the characteristics of products with a partially steel core. But the power of water hammer can reach 15 - 30 atmospheres, but such tests of aluminum are not under force;

- In addition, aluminum structures cannot work in systems where copper is present. In the case of direct contact of aluminum and copper, the process of electrochemical corrosion begins, which inevitably leads to the destruction of aluminum components;

Important: the solid copper-aluminum construction of bimetallic radiators of heating provides for the arrangement of a layer between these metals. The process is quite complicated and expensive.

- Another limitation for aluminum parts is the pH of the coolant. The upper limit here is 9 units, but it is better not to “crawl out” for 7–8 units;

- Despite the high strength and other advantages, aggregates with all-steel core have weaknesses. The first thing that catches your eye is the high price of products. Plus, the heat output of such batteries is 10% lower than that of mixed designs and 15-20% lower than that of pure aluminum models;

- Weighing the pros and cons of bimetallic radiators of various types, we concluded that mixed aggregates with pressing pressure up to 25 atmospheres and two vertical channels are quite suitable for standard "Khrushchev" or nine-story buildings;

- Modern sky-high skyscrapers require a more serious approach. Here, preference should be given to a one-piece steel core, preferably stainless steel;

- As for the private sector, with its low-power local systems, if the piping is plastic or steel, it is quite enough, relatively inexpensive aluminum batteries with high heat transfer.

Tip: we noticed that in the catalogs and on the pages of specialized sites, the description of some models necessarily contains the mention that the coolant is in contact only with steel pipes. The rest are modestly silent about this moment. So, upon detailed examination, such aggregates are mixed.

Technical details

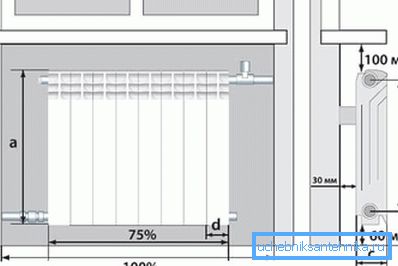

The standard device of bimetallic radiators is shown in the diagram. But, despite the general principle of the layout of nodes, the characteristics of models from different manufacturers can vary greatly among themselves. As you understand, publishing the parameters of all models presented on the modern market is unrealistic. Therefore, we will talk about the average data.

Heat transfer or the amount of heat released into the room for such products is simply luxurious. If we talk about the full bimetal aluminum-steel, then the figures are about 160 - 180 watts. Mixed units are capable of delivering 170 - 200 watts from one section.

Speaking about the combination of copper and aluminum, it should be noted that the heat transfer of such panels is almost the same as pure aluminum. On average, it is 200 - 220 watts. According to GOST standards, all these data are correct at a coolant temperature of 70? С. Accordingly, the deviation in any direction will entail a decrease or increase in heat transfer.

The maximum pressure that most bimetallic structures can withstand, ranges from 16 to 25 atmospheres. Nevertheless, reputable manufacturers guarantee that their mixed aggregates withstand up to 30 atmospheres, and products with an all-steel core are able to withstand 40 atmospheres and higher.

Another advantage of such batteries is a wide range of axle sizes. The axial size is the distance between the horizontal axes of the upper and lower entrances. Here it is 200 mm, 300 mm, 350 mm, 500 mm and 800 mm. As you can see, there are plenty to choose from, although the 500 mm size is considered the most common.

Important: many manufacturers specify the upper temperature limit of the coolant to 100 degrees or more. But most experts argue that even the highest quality bimetal is not able to withstand temperatures above 90? С. Everything else is more related to the field of marketing.

As for durability, on average, manufacturers say about twenty years of warranty and there is no reason to doubt it. Some solid panels with copper or stainless steel cores can work for up to 50 years.

Also, many marketers say a small amount of one section of the battery, on average, it fluctuates around 200g, this is really true. On the one hand, this is of course good, because the smaller the volume of coolant, the easier it is to heat it and control the temperature afterwards.

But on the other hand, small capacity is achieved due to thin internal channels, and this increases the likelihood of their blockage, especially in centralized urban systems.

Calculate the number of sections

In principle, all that is needed to do the calculation of the number of sections per room is the thermal power of one section. Any accompanying instructions to the product or company product catalog contains this data. But you can count, based on the volume, area or heat loss in the room.

Calculation of heat loss, as a rule, makes a professional heat engineer. Here, in addition to traditional data, the mass of various coefficients and corrections is taken into account. For example, such as the thickness of the walls, the material from which the house is built, the number of floors, and so on. This is quite painstaking work and most often such calculations are made at the stage of building a house.

For the calculation of the volume of the room, standard standards are used, indicated in the respective SNiP, according to these data, in order to maintain an average temperature of 20? С in 1 m? space in the panel house consumes 41 watts, for structures built of brick this value is 34 watts.

Then everything is simple, you need to multiply the length, width and height of the room and, according to the resulting cubic capacity, calculate the approximate amount of heat needed to heat the house.

Knowing the design capacity that one section is capable of issuing, it is easy to calculate the number of sections. This method is often used in the construction of private cottages or premises with a non-standard layout.

As for the calculation of the area of the room, it is recognized as the least accurate. As a rule, it is used by residents of standard city apartments, with ceilings no higher than 3m.

According to the same SNiP, one square meter of living space requires 100 W for heating. Multiplying the quadrature by 100 W and dividing by the power of one section, you get the number of sections.

Tip: both calculation by volume and by area, do not differ in tabular accuracy. Therefore, if there is more than one exterior wall in the room, an unheated attic or a balcony, then you can safely increase the data by 20%. Also, do not forget about the water temperature in our urban systems, it is safe to throw another 10%.

The video in this article contains information on bimetallic radiators.

Conclusion

The advantages and disadvantages of bimetallic radiators of heating suggest that they should be installed in urban high-rises or in private cottages with an aggressive coolant, such as antifreeze. In other cases, it makes no sense to pay for such high quality and reliability.