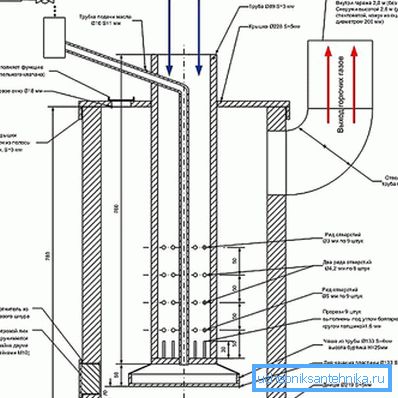

Waste oil boiler itself

Many car owners (especially trucks) are faced with the problem of recycling waste oil. Since the substance is toxic and poisons the environment, it is not so easy to get rid of mining. In addition, you can get a real penalty from environmentalists. To burn such waste in special equipment for the benefit of oneself is one of the acceptable outputs. The industry has long been producing boilers running on waste oil. But they are expensive, and therefore home craftsmen are looking for ways to build a water boiler on the waste oil with their own hands.

How does it work

The algorithm of the boiler is very simple:

- From a special tank to the pyrolysis bowl is working out (you can any synthetic or mineral oil, a mixture of them, in extreme cases, kerosene).

- In this tank, the mining is brought to evaporation (heated by exhaust gases and a burner).

- Oil vapor enters the combustion chamber, where it is mixed with air and ignited by a burner. During combustion, a large amount of energy is released, which is able to heat (through the walls of the chamber) the coolant for heating the room.

- Waste of combustion (there are few of them, but there is one) is removed through the chimney, which has a vent for gases. In this way, the heated gases enter the pyrolysis chamber and heat the mining, and then are removed outside.

To regulate the intensity of burning oil in the upper part of the chimney install gate valve.

Tools and materials

In order to independently assemble a water boiler using waste oil, you should have assembly drawings. This documentation will help avoid errors and make a workable design. But you should start with the tools. For work you will need:

- welding machine (inverter);

- "Bulgarian" and a set of cutting wheels for cutting metal;

- electric drill;

- a set of keys (adjustable, gas, etc., as required);

- hammer and other plumbing tools.

The next step is the selection of components for the assembly of the boiler. Based on the drawing, the construction of a home-made boiler consists of the following elements:

- expansion tank with a membrane;

- housings for the boiler and the oil vapor combustion chamber;

- a centrifugal pump that can operate in the state of immersion in oil (feeds oil into the pyrolysis chamber);

- a compressor that, under pressure, supplies air to the secondary combustion chamber;

- circulation pump for the forced movement of the coolant;

- chimney with gate valve and gas outlet;

- burner;

- fittings and pipes for connection to the heating system.

The burner can also be made by yourself.

Boiler assembly

The design of the boiler body consists of two pipes of different diameters. The gap between them should be 3-4 cm (for filling with water). The outer casing has two outputs (feed / return). Inside the second pipe mount the combustion chamber of oil vapor. Water in no case should get into the department where the oil burns. The oil container is placed near the boiler. A pump is immersed in it, which, under pressure, supplies fuel to the pyrolysis chamber.

To stop the flow of oil in the pipeline is mounted valve.

In the lower part of the construction, an oil tank is mounted. Its upper part has openings for the release of gas vapors into the secondary combustion chamber, and at the bottom there is a door for easy cleaning of the chamber. Through the door you can lead to the candle burner electrical contacts. In the tank for liquid oil, its initial ignition takes place, and it also works as a spark plug.

A fitting for an air duct (creating an air-oil mixture) is cut into the secondary combustion chamber.

In the upper part of the secondary combustion chamber, a chimney with a gate valve and a gas outlet tube is installed, which goes down to the bowl with oil, heating it with exhaust gases. On the return water line install the circulation pump. At the pitch, an expansion tank and safety automatics are mounted.

Start to work

Before starting, check all welds for tightness, fill containers with oil and water. Oil should be poured to a layer of 1 cm, it should not be water and debris. The oil will burn faster if 100 ml of kerosene is added to it. The boiler is set on fire with a wick dipped in a kindling liquid; after ignition of the fuel, it is lowered to the bottom of the tank. Then turn on the air supply. After boiling the oil is evaporated and begins to heat.

Advantages and disadvantages

The positive characteristics of the equipment include:

- Universality and cheapness of fuel (different oils are suitable for work).

- Environmental friendliness - a pair of oils burn almost completely, emissions to the atmosphere are negligible.

- Greater heat dissipation. When using forced ventilation or circulation, the heating rate of the room increases several times.

- The simplicity of design and low cost components for assembly. The costs will be repaid during the first year of operation of the boiler.

Disadvantages of equipment:

- As the oil is heated over an open fire, a large amount of oxygen is burned where the boiler is installed. For safety, you must take care of airing this room.

- Will require the cost of the purchase of filters, because waste oil can contain chips and other solid particles that quickly contaminate the burner.

- Oil need to defend, and only then pass through the filters.

- After stopping the supply of oil, the boiler goes out after a while, because until the fuel in the primary combustion chamber burns out, its operation will not stop.

- Waste oil boilers should not be used in residential premises due to unpleasant odor and the possibility of carbon monoxide in the room.

If you need to organize the heating of utility rooms, garages, warehouses, etc., then a water boiler with waste oil is quite an economical and profitable option. You can also heat the living quarters by installing the boiler in a separate boiler room.

Video

The video shows what the waste oil boiler is:

Blueprints

The drawings show how to make boilers and furnaces for testing: