Waste-oil heating stoves - features and fabrication

Each owner seeks to reduce heating costs to a minimum, which is achieved using heaters that work on the most affordable types of fuel. In some cases, the cheapest energy carrier is waste oil, which accumulates in repair shops and service stations.

In this article we will look at the devices of furnaces operating on this fuel and how to manufacture them independently.

Manufacturing

The design of a homemade oven

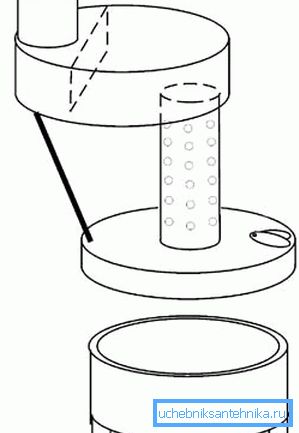

The furnace, working on the development, has a fairly simple design and consists of the following elements:

| Lower capacity | It is a tank into which oil is poured. The container should be provided with a hole for filling the oil, as well as a hole for adjusting the intensity of combustion. |

| Burner tube with holes | Designed to enrich the fuel vapor with oxygen. |

| Top tank | Serves as the main heating module. |

| Chimney | Carries out the removal of combustion products. The design should be made of heat-resistant pipes using high-quality fittings. |

Tip! You can improve the heating of the room by combining the chimney with the brickwork. This is due to the fact that the heated brick is longer than the iron gives off heat.

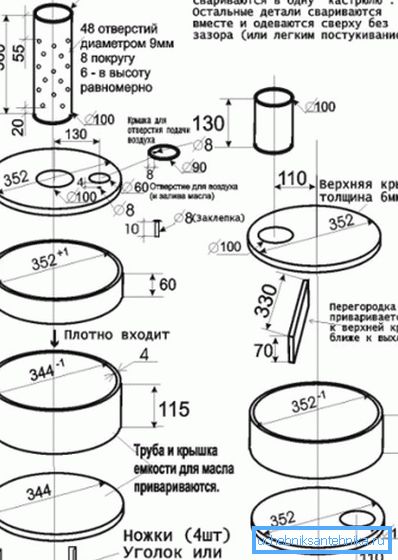

Tanks are made of steel sheets 4 mm thick. The top cover of the second tank is made of a thicker steel sheet - 6-8 mm. This allows you to increase the life of the device, as it prevents its rapid burning.

In addition, there are certain requirements for the connecting pipe:

- The diameter must be at least 100 mm.

- The length should be four times the diameter.

- Over the entire area of the connecting pipe it is necessary to drill holes with a diameter of 9 mm. As a rule, they are arranged in six rows, with 8 holes in each. The result should be 48 holes.

The design is located vertically. At the same time in the upper tank is the pipe for the chimney. Legs are welded to the lower part, for example, metal corners.

To give the product a more aesthetic look, it can be colored with a mixture of the following ingredients:

| Liquid glass | 500 milliliters |

| Aluminum powder | 200 grams |

| Ground chalk | 20 grams |

Tip! The process of making the stove can be greatly simplified by using an oxygen or gas cylinder, and not welding sheets of steel. Such a capacity can last for many years, as it has sufficient wall thickness.

Some nuances of manufacturing

Before proceeding with the manufacture of the unit, we recommend that you familiarize yourself with the following nuances of this process:

- The dimensions of the device can be any, the only thing to increase or decrease the design should be proportional. Therefore, you should first make a drawing with the dimensions.

- The diameter of the holes in the connecting pipe should be 10 percent of the diameter of the pipe itself.

- Oil fill and air caps should turn easily on a bolt or rivet. By adjusting their position, you can change the fuel consumption and heat power of the device.

Note! The upper part of the structure heats up the most, so it can burn out a year after the start of operation. To increase the life of the upper tank, install a fan at a safe distance. This solution will increase not only the durability, but also the efficiency of the furnace.

As we can see, the instructions for the manufacture of such a design is quite simple. Therefore, to make it under the force of every home craftsman who knows how to work with a welding machine. Otherwise, you can seek help from a professional welder.

Features of the furnace to work

Exploitation

The considered design of the stove provides air heating.

The process of its operation is as follows:

- Before igniting, inspect the chimney and lower container for water ingress.

- Then through the hole in the tank it is necessary to fill in 2-3 liters of oil.

- Next you need to make a wick out of rags, oiled it and set on fire.

- The burning fuse is pushed through the hole, and thus the oil is ignited. As a rule, it takes from one to five minutes to heat up the oil. This process can be accelerated by adding a small amount of kerosene to the fuel.

At the same time for the safe operation of the device, you must observe the following rules:

- It is strictly forbidden to use acetone, gasoline or other flammable liquids instead of oil, as in this case an explosion is inevitable.

- It is not advisable to allow water to enter the oil, as this may result in a burst of flame.. Accordingly, in the event of a furnace ignition, water cannot be used to extinguish the flame.

- It is possible to operate the furnace only in a room with a working ventilation system, otherwise accumulation of carbon monoxide is possible.

- Around the oven there must be at least 50 cm of free space.

- The stove should be located on a perfectly flat horizontal surface.

- Do not leave inflammable materials or objects near the device.. In addition, such substances should not be operated near a working heater.

Merits

Among the advantages of these furnaces are several of the most important points:

- As mentioned above, such a stove is not difficult to do with your own hands.

- The unit is very economical in operation, in addition, in most cases you can get the fuel almost for free.

- The failure of the furnace is excluded due to the simplicity of its design.

- The upper surface of the furnace can be used as a cooking.

disadvantages

As for the cons of this furnace, there are not so many of them:

- Since the unit does not have a forced removal of exhaust gases, it needs a chimney with a good natural draft, at least four meters high.

- Chimney on any of their sites should not pass horizontally.

- The device requires regular maintenance, namely, it is necessary to clean the chimney and oil tank once a week.

- The stove can heat only a small room, for example, it can be used to heat a garage or a small country house.

Thus, an oil stove may not always be a solution to the problem of heating a dwelling. In some cases it is better to pay attention to a more complex structure, which is described below.

Waste oil boilers

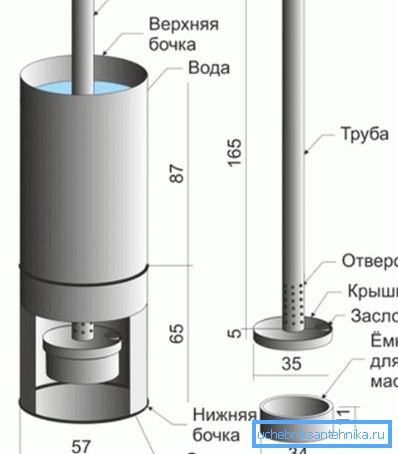

Efficiently heat a large house can furnace for working out with water heating. It should be noted that these devices are more difficult to manufacture, so for security reasons, it is better to buy a ready-made device, and not to manufacture it yourself.

However, if you still decide to do the boiler yourself, the simplest construction is shown in the diagram below. In fact, this device is not much different from an air furnace, the only one, instead of the upper heating module, it uses a water tank. Its volume depends on the required power of the heating system, which is calculated in accordance with the volume of heated premises.

In this case, a pipe that passes through the entire tank is used as the heat exchanger. The lower part of this pipe, as in the air furnace, has holes and serves as a burner.

As shown in the diagram, two barrels can be used as the body for the boiler. In the lower barrel, a cutout must be made to provide access to the fuel tank.

In the upper tank, two holes are made, to which the inlet and the outlet are welded. Moreover, the inlet should be at the bottom of the tank, and the output - at the top.

Of course, the price of this design will be significantly lower than the original boiler, however, it should be noted that the latter have some advantages, in particular, many branded models can work in automatic mode.

Here, perhaps, are all the main features of manufacturing boilers running on waste oil.

Conclusion

Furnaces and boilers for waste oil, have a fairly simple design and at the same time differ in efficiency. Therefore, it is not uncommon to be an excellent choice for space heating. In addition, as we found out, they can even be done independently, adhering to the above recommendations.

From the video in this article, you can get more information on this topic.