Water convectors heating - heat without delay

Using water as a coolant is a cost-effective idea. Increasingly, instead of the usual batteries, water heaters are installed in the apartments. Such advantages as: safety, compactness, exclusive design only contribute to the growing popularity of convectors.

Design features

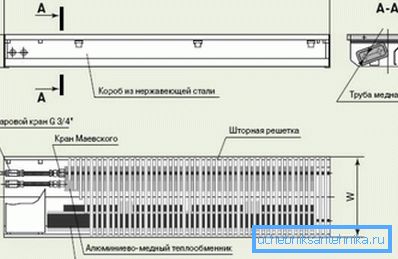

Externally, the unit is a rectangular solid body of, covered with a grid. The floor version is like a small bench, the wall version is a panel of a small thickness, and the embedded ones can be seen only through the grille.

The classic casing is made of stainless steel. But, given the design features of the room and the wishes of customers, the body can be made of wood, marble chips or MDF panels.

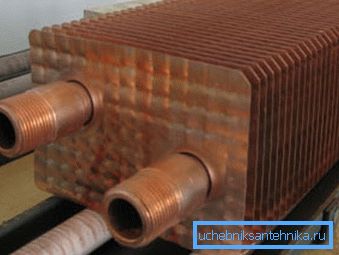

Ascetic outside, inside the convector of water heating are more complicated. Their "heart" is considered to be a heat exchanger, which is a copper flat or a pipe in the form of a coil. On it perpendicular to the method of tight fit lamellae are attached.

The place of their connection with the pipe should exclude the slightest gaps that reduce heat transfer. Copper is most often used for the manufacture of plates, there may be variations of steel and aluminum, the main thing is that the thermal conductivity be at a height.

Note! Given the constant contact with water, this element must also be resistant to corrosion. So non-ferrous metals are preferable.

Connection to the riser or the central pipeline is carried out through special inlets with a thread inside, which are located at the end of the device or at the side. On modern heating water convectors taps-valves or manual / automatic valves are installed to release excess air, which impairs heat transfer.

If an electronic thermostat / thermostat is included in the package, it will monitor the working rhythm of the device. The heating process periodically stops when the set temperature is reached and begins again when the air cools.

To enhance air circulation, a fan is used, which is either already built in, or it will have to be purchased. This useful addition (1–2 pieces) is found only in floor heating convector heaters for heating.

How convection helps keep warm

Unlike conventional batteries, which warm the air by radiating heat from their surfaces, water heating convectors act differently. They mix air masses, replacing warm air with cold and creating a pleasant atmosphere. It does not feel the dryness and the specific unpleasant smell of burnt dust.

Hot water from the heating system enters the heat exchanger and heats the plates. Given the thermal conductivity of the material used, as mentioned above, the parts heat up very quickly. Through the holes in the lattice, warm masses rise freely, displaced by cold masses.

The built-in fan stimulates this process, and after a few minutes you can already feel the result. At the same time, the efficiency rises to 95%, which makes it appropriate to use water convectors in spacious rooms with large window and door openings.

In accordance with the requirements of GOST 20849-94, water heating convectors must have the first essential feature - tightness and strength, which is checked with a test water pressure of 1.5 MPa. The heating elements and the housing must be coated with an anti-corrosion, heat-resistant composition.

Among other things, the water convector of heating is relatively inexpensive, given its growing popularity. Installation by specialists of wall, floor or plinth construction will cost you almost twice cheaper than the internal one. This price is justified by the complexity of the preliminary work on the device niche in the raised floor.

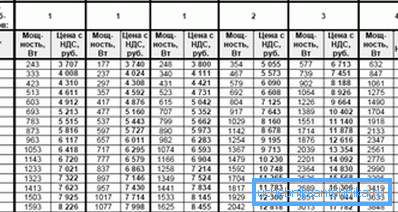

Brief description of typical convectors

Their technical characteristics are important for water heaters; it is on their basis that a specific model of heater is selected.

The characteristics of most typical convectors are within the following limits:

- maximum allowable pressure during operation is 16 bar;

- pressure testing - 25 atm;

- water temperature can reach 130 ° C;

- maximum case heating - 60 ° C;

- the heat exchanger can be 4 or 6-row;

- the volume of water in the heat exchanger is 0.7–0.9 l;

- throughput per hour from 90 to 170 liters;

- power from 100 to 200 kW;

- weight ranges from 14 to 21 kg.

Assembly work

Installation instructions for water heaters are simple and consist of connecting to a heating pipe. In-floor models are installed simultaneously with the floor device, wall or baseboard models can be installed at any time.

The installation process includes the wiring of electrical cables, coolant supply circuits, and a niche device for the unit box, which should be flush with the final floor. It is better to entrust this work to qualified specialists.

Note! Calculate the capacity of the installation, too, instruct a specialist, if you are not a heat engineer, you can not take into account, for example, heat loss when calculating heating. You will need information about the area of the room, its insulation and the height of the ceilings.

Depending on the purpose, the heating water convector can perform 2 functions:

- heat the room - the device is installed away from the window openings;

- create an air barrier to cold air in the window area - a heater opposite the window at a distance of 20 to 30 cm.

Impeccable heating is achieved by complying with the following installation conditions:

- Coolant inlet / outlet is made of rigid or flexible connections and shut-off valves (included).

- The convector niche should have such a depth that the decorative cover of the device is flush with the finished floor.

- Allowable gaps on the width and height of the convector from 10 to 15 mm.

- Adjusting bolts convector water heating horizontally aligned and secured.

- Gaps are insulated and sealed with a special material..

- After installing the finished floor connect eyeliners (electric is necessary if there is a built-in fan).

- Seal the remaining gaps with sealant / finishing material, turn on the device and cover with a grid.

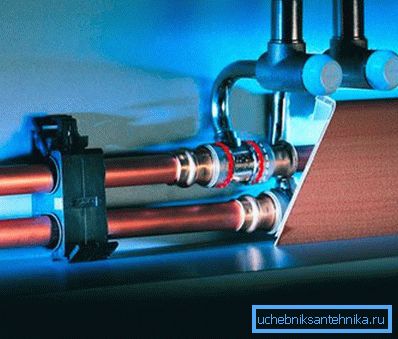

Installation of wall and plinth heaters does not have so many nuances and consists in connecting the object to the water supply network, and this is easy to do with your own hands.

Before working with a wall heater, you need to remove the battery, then proceed directly to installation.

- Instead of radiator plugs, screw two couplings with the same diameter, usually 20 mm, onto the sleeves.

- On the brackets, fix the convector and align its axis with the axes of the threads.

- Wind the threads on the heater, push the couplings up to the stop and tighten the lock nuts.

- In order to avoid water hammer, starting the riser, open the valves slowly.

Note! When connecting the plinth model to the urban heating system, use multilayer plastic pipes made of cross-linked polyethylene with special fittings. The second option is soldering with copper fittings for pipes. This will protect your design from tricks with changes in water temperature and pressure surges.

Summarizing

The use of water convectors - the cheapest form of heating. A variety of installation installations allows you to gently warm the room without drying out the air. Temperature control systems allow you to maintain a constant thermal threshold, saving the family budget.

The video in this article will demonstrate in detail and with ease the installation process of a water floor convector.