Water floor heating itself

Each person seeks to furnish housing with all the necessary things and to take advantage of new technologies that create the desired atmosphere and comfort. An important factor in this issue is heating, which heats all the rooms in the cold season. If it was previously decided to install standard heating with iron pipes and cast iron batteries, then today you can find many alternative options.

One of these is a heated floor, which is not only pleasant to walk on, but also provides enough heat to maintain the optimum temperature in the room. There are several options for arranging underfloor heating, but the most common and accessible is a water system. Arrange water heated floor is not very difficult. In this article we will explain how to make a water-heated floor with your own hands in a private house, we will give a step-by-step instruction for installation and installation.

Benefits

As you know, the most comfortable temperature for a person is +18? С. It can also be maintained by a conventional heating system, but when it comes to flooring, which can be very cold due to direct contact with the foundation, higher rates are needed here. Thanks to the water floor system below, the air warms up to +22? С. In addition, there are other benefits that the user will receive when using modern technology:

- No dust circulation.

- Reducing the likelihood of fungus formation in the corners.

- Normalization of air humidity.

- Convenience of operation and care.

- Absolute security.

- Compatible with different types of heating.

- Long service life.

A weighty argument in favor of the warm floor is the lack of direct and visual contact with the heater, which allows you to freely plan the interior of the room.

Basic layouts and types of pipes

To heat evenly distributed over the entire surface, it is necessary to choose the right way of laying. Since the water will gradually cool, the installation must start from the walls and move according to the chosen scheme. To organize a warm floor, you can use the following schemes:

- Snake - bypassing the perimeter of the room wavy line from the outer wall to the next wall.

- Snail - constantly goes around the perimeter, moving to the center, each new circle will be less than the previous one.

- Combined - includes both styling options at the same time.

Studying the various installation options, everyone is faced with the problem of choosing the type of pipeline. To date, you can use these options pipes:

Copper

Treat expensive materials. At arrangement of a heat-insulated floor it is necessary to cover them as the coupler can adversely affect them. Pipe laying requires special equipment and knowledge in this area, so a beginner will not be able to cope with the tasks.

Metal plastic

Metal pipes are often used when installing a heated floor, as the material is quite durable, takes a different shape. They are easy to install. Also in the list of benefits include resistance to stress. After bending, regardless of the temperature of the heat conductor, the shape does not change.

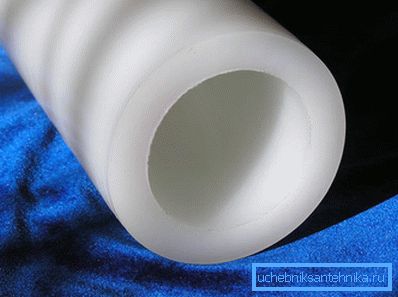

Polyethylene

In this case, cross-linked polyethylene is considered (the density of cross-linking may be different), which is not afraid of freezing. It should be remembered that at high temperatures the pipes will straighten. Connection of pipes among themselves does not take a lot of time.

Polypropylene

To date, plastic products are very popular in various fields. Polypropylene pipes are often used in modern heating systems, but this option is hardly suitable for floors because of the large bend radius.

It’s impossible to say which pipes are better. It is important to calculate everything in advance to determine and purchase the necessary material.

Preparatory stage of the system installation

To study the information on how to make a warm floor on your own, it is necessary in order and first of all you should familiarize yourself with the preparatory work. At the first stage, the surface is prepared:

- If the floor is installed in the living room, then all the furniture is taken out.

- If the flooring is still to be used, it must be dismantled carefully.

- To comply with the technology, it is necessary that the pipes are laid at a sufficient depth. This can be achieved by partially or completely removing the old screed. To carry out these works, you need a powerful hammer drill or an electric jackhammer. Before starting work, you need to know to what level you can move. For this, a small layer of the surface is knocked out and the distance to the concrete slabs is inspected (in the case of an apartment). In a private house with a small thickness of the casting screed, you may have to remove it completely and remove part of the bedding.

- After the recess has been made, all the space of the exposed plates is carefully removed. Do it better with a special construction vacuum cleaner. If the installation takes place in a private house and I had to remove part of the bedding under the screed, then you need to tamp the base well. This is done by a self-made tool (it can be assembled from a board of 20? 20 cm; a bar of 50? 50 mm and a transverse handle is attached to the base) or by a vibro-rammer. The latter are both gasoline and electric. For those living in an apartment, more sparing methods of tamping are needed, otherwise the ceiling of the neighbors will suffer from below.

- For the next stage, you will need metal fittings with a diameter of 8 × 10 mm. You need to make a crate out of it. If the height of the future tie will be up to 10 cm, then one level will be enough; when lifting 20 cm or more, it is better to make it in several levels. To do this, two identical planes are made, inside the grid is laid out with a pitch of longitudinal and transverse rods of 40 cm. The grids are interconnected by spacers of the required length. All actions can be performed using knitting wire. In some cases, if actions are carried out in an apartment and the draft screed will be up to 10 cm, then metal beacons are put up by level and the foundation is poured without the use of a batten. Using the rule, the solution is aligned and the plane is displayed.

- Within three weeks, it is necessary to allow the flooded layer to stand, so that it becomes stronger and does not float during the course of further work.

If the apartment does not plan to remove the old screed, but the floor still needs to be leveled, then self-leveling compounds can be used. To work with them, it is important to observe the ratio of components recommended by the manufacturer. If the space is larger than indicated on the package, then the territory should be divided into sections. You can separate them with the help of polyurethane foam, for it the solution will not flow. After pouring over the area, it is important to walk with a needle roller to remove air residue to improve adhesion.

The main stage of work

After the preparatory work, you can proceed to direct installation.

- We make cleaning. It is best to coat the frozen and strengthened screed with a primer. This can be done in one layer. This will remove unwanted dust and strengthen the surface.

- The whole area is covered with waterproofing. For this purpose, a polyethylene film with a thickness of 200 microns is used. The canvases are overlapping, it should be at least 10 cm. The seams are taped with ordinary duct tape. Turns are made on the walls by 5 cm.

- A damper tape is glued around the perimeter. Its height should be such that it stands for the layer of the future screed with insulation. It is made of foamed polyurethane and is necessary in order to compensate for the expansion of concrete when heated.

- The next layer is insulation. For these purposes foam or foam plastics is used. Their minimum thickness should be 3 cm. If this level is planned to be 6 cm thick or more, then it is best to lay in several layers. In this case, they must be positioned so that the seams are intertwined and not superimposed. This is important, since they will not diverge under the load of the finishing screed.

- For greater convenience, it is better to use the upper layer of insulation with lugs (special plastic protrusions, between which the pipe is laid). If this is not possible, then a metal grill will fit in 10–15 cm increments. In the first case, the pipe presses well due to its design features, and the turns are fixed with plastic clips. In the second, wire is used for fixation.

- Next set collector cabinet. In order for it to occupy less space, it is usually sunk into the wall. Niche is made using a hammer drill with a chisel. For fixing the box itself, holes are drilled, dowels are inserted into them and screws are clamped.

- Inside the installed cabinet two collectors are mounted (one supply, the other for reverse current). For easier follow-up service when buying a tip, the valves are collapsible. Also consider the possibility of adding additional contours, perhaps this will be required in the future. The splitter is connected to the main circuit from the boiler.

- The pipes are laid according to the previously selected scheme. It should start from the collector and further from the outer wall to the middle (when laying by a cochlea). It is important that on the approach to the splitter all the pipes are insulated. This will prevent excessive overheating of certain areas.

- The area of one circuit should not exceed 40 m2, in the case when the room is larger, then it needs to be divided into several contours.

- The length of the pipe in one circuit should not exceed 80 m with a diameter of 16 mm and 120 m with a diameter of 20 mm. This is due to the fact that there can be large pressure and temperature drops.

- Pipe connections are not allowed at the site. If, however, such a need arises, then make them better by crimping. For collapsible connections, you will have to leave a revision window for maintenance in the event of a breakdown.

- After the pipe is laid, the entire system is crimped. To do this, it is filled with air or water. The pressure builds up to a value that is 8–10 times the nominal working. In this state, the system is left for a day. The fall should be insignificant - it is allowed to expand the pipe. The entire length of the pipeline is checked for damage.

- Preparing a solution for screed. It will definitely need to add a plasticizer. This will make the mixture more elastic. The ratio of cement and sand will be different for a particular brand, usually it is indicated on the packaging. Plasticizer will need at the rate of 1 l per 1 m2.

- Filling is done so that the pipes remain under pressure. During operation, you may accidentally damage the contour with some tool. It is better to reveal it now than after everything is frozen.

- Full maturation of the concrete screed takes 28 days.

- After drying, you can cut off the excess damping tape and lay the tiles.

The laying step is determined depending on the purpose of the heated floor. If this is the only source of heating, then the pitch should be 15 cm, and if the auxiliary is up to 30 cm. In the case where several circuits were provided, a damper tape should also be placed between them in the screed.

Other options

In addition to the cement method of laying, laying the pipeline on a polystyrene and wooden base has also become widespread today. The general principle is that there is no need to fill the finishing screed. In the first case, the plates of insulation also serve as a guideline for laying pipes, for this special channels are provided.

Before laying the contour, special metal plates are placed, which will increase the heat transfer area. In the second embodiment, the insulation is mounted between the lags. Chipboard sheets are laid on top, in which, like in the first variant, grooves for the conductor are cut out. Metal plates are mounted in the same way. On top of everything is covered with a finishing coating, in the role of which a laminate or other material can act.

The advantage of these options is that they do not exert additional pressure on the floor. For example, it can be used on the second floor of a wooden house.

Let's sum up. It is possible to make a water-heated floor on its own. It is necessary to calculate everything, choose a pipe laying scheme and consult with experts. With proper installation and compliance with the entire technology, warm air will be evenly distributed not only around the room, but also in neighboring rooms, starting from the lower layers.

As a replenishment of the knowledge base and expanding the horizon, we suggest you read the article "How to properly lay a warm floor under the tile"

Video

Watch the video about the installation of metal-plastic pipes for arranging underfloor heating:

In this video you can see the process of installing a heated floor using a polypropylene pipe: