Water-heated stoves are a cheap and practical solution.

In country houses, and in the private sector within the city limits, stove heating is often used. If desired, using the same wood-burning stove as a heat source, it is also possible to arrange water heating, this will not cause a significant rise in price. As a rule, in such cases use purchased stoves with water heating.

Advantages of water heating

Water heating in many ways exceeds the air, namely:

- water is available, even in the most remote areas with water supply, there are no special problems;

- it has a much greater heat capacity, so that the heating efficiency will be at the height;

- a water stove with heating will allow to organize uniform heating of all rooms; using a simple stove, the heat source is point-like; this will not allow all the rooms to warm up evenly;

- in this case, the heating system at home can be adjusted without any problems; it is enough to install thermostats in front of each radiator.

Among the shortcomings worth noting:

- the negative effect of water on the metal;

- in addition to the cost of the stove itself, you will have to spend money on radiators and pipes. As a result, the price of the heating system will increase;

- suitable only for permanent residence in the house. If visits to the dacha during the cold season are rare, it is better to stop at the usual stove-heated housing. Regular freezing water will easily tear the pipes.

Note! Instead of water, antifreeze can be used as a heat carrier (ethylene glycol or propylene glycol is most often used). In this case, a 15-degree frost will not be a problem.

More information about the water heaters purchased

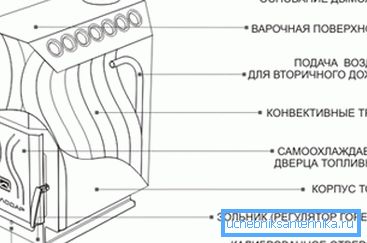

The main thing that distinguishes a stove for heating a house with water heating from a conventional one is that it houses a heat exchanger and the manufacturer has holes for connecting pipes. It turns out a kind of mini-boiler with the only difference that the device is placed directly in the living room.

Classification

The principle of operation of such furnaces does not differ from the ordinary ones, therefore the classification remains the same.

By the principle of action, you can select:

- with one camera - in them the fuel just burns through, and the released energy goes to heat the water in the heat exchanger;

Note! The heat exchanger in the furnace for water heating of the house should be made of thick steel (at least 5 mm). If you use a thin metal, then it can simply burn through a long-term operation of the furnace.

- pyrolysis - they are distinguished by the fact that the firebox is divided into 2 zones, in one of which the pyrolysis gas is being burned;

- brick stoves for a house with water heating - a very controversial option, the features of devices of this class are discussed below.

It is possible to classify by type of material (for the production of sheet steel or cast iron). Both materials provide high thermal conductivity, but cast iron has a slightly higher thermal conductivity.

A slight disadvantage of such stoves is that, apart from heating the house, they are not suitable for anything else. Maximum - a small hob, which will warm and cook food.

Heating system arrangement

As for the main elements of the heating system, they remain the same as when using boilers.

Not taking into account the stove with a water circuit, you will need:

- circulation pump for heating;

- pipes;

- expansion tank (it will allow to compensate for an increase in the volume of coolant during heating);

- radiators;

- If you wish, you can purchase thermostats and install them before each battery.

Water heating from the furnace with their own hands begins with the choice of the installation of the stove meta. If in the case of convection heating, it is desirable to place the stove in the center of the room in order to achieve at least some uniform heating, then adding a water circuit removes this restriction. It can be placed in the corner of the room without reducing the efficiency of the heating.

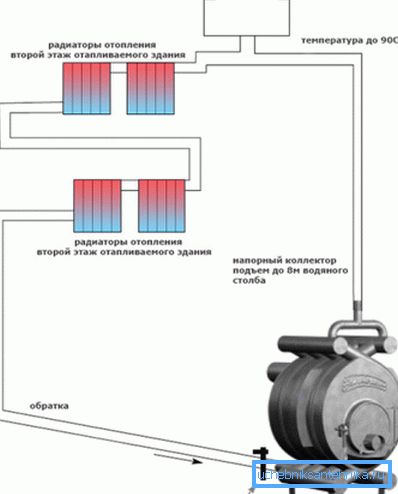

Then the pipes are laid on the floor / floors, radiators are installed, connected to the pipes, and finally, the supply pipe and the return pipe are connected to the stove itself, the heat carrier is poured. It remains only to check the tightness of the system and you can proceed to the furnace.

As for the heat exchanger, its shape can vary greatly depending on the manufacturer. For example, the Buleryan water jacket (also known as the Aqua Breneran oven) has a heat exchanger in the form of several pipes that fit snugly to the firebox inside the case, that is, the design of the heat exchanger is designed as a register. But there are models with flat heat exchangers.

Note! Still, the capacity of such stoves is lower than that of heating boilers, so that the volume of coolant in the system is small - about 40 liters for a medium-sized house.

It should be noted that at the exit of such a stove, the temperature of the heat carrier may well exceed 90? С. Therefore, if the house wiring is done with the help of a PP pipeline, then at the exit from the boiler it is better to use a small piece of metal pipe - just insurance.

Brick stove with a water circuit

A stove for water heating may well be lined with bricks. True, both in terms of cost and complexity of work, this option cannot be compared with purchased models. It is impossible to add a water circuit to an already laid out stove, you will have to shift part of the stove. Therefore, it is recommended at the brick laying stage to attend to the placement of the heat exchanger in the masonry.

Design features

The main task of the stove is to install the heat exchanger in the stove.

As for the heat exchanger itself, then its shape can be any, most often used are such options as:

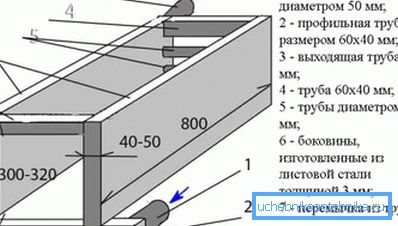

- the register of pipes - a disadvantage of this type is the complexity of welding (when using round pipes;

- can be used in the form of a tank of sheet steel (the thickness of the steel should be at least 5 mm);

- the heat exchanger can be made in the form of 2 tanks connected by pipes.

Note! When working with your own hands, it makes sense to use shaped tubes. This will facilitate welding work.

Separately, it is worth considering the options for placing a heat exchanger - the complexity of the work is directly dependent on this.

Such options are possible:

- placing directly in the firebox - this arrangement is optimal for stoves with a large cooking surface. To install, simply remove the metal plates from the top and place the register inside. But there is also a significant minus - the size of the register should not significantly reduce the internal space of the firebox;

Note! Do not place the heat exchanger against the walls of the combustion chamber. When heated, the metal expands, so you need to provide a gap of at least a couple of centimeters.

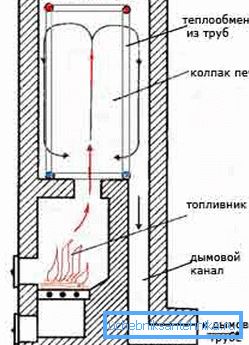

- a stove for a house with water heating can be equipped with a heat exchanger installed in the smoke circulation or simply in a cap that is arranged so that the combustion products give off heat to the walls. But in this case, the installation design is carried out either during construction or when disassembling the stove.

Well, special attention should be paid to the quality of welding. Even a small lack of penetration in the future can turn into big problems. It is good if the heat exchanger can be easily removed from the fuel chamber and repaired. But, if it is placed in the smoke, you will have to disassemble the furnace for water heating, and in the middle of the heating season, such surprises are not needed.

Advantages and disadvantages of brick furnaces for water heating

Brick kilns with integrated water circuits have a number of serious drawbacks:

- heating circuits with poor circulation will definitely not work, so you can forget about completely autonomous heating;

Note! Coolant without proper circulation can boil in the heat exchanger for a couple of minutes. It is good if in this case it will be easy to frighten, but the depressurization of the heating circuit is much more likely, because the pressure will increase significantly.

- such a water heater for the house will be unregulated. If, for example, in gas boilers, the burner operation is monitored by the automatics and there is no problem to turn it off, then brick stoves accumulate heat perfectly and they will cool down for long hours;

- operation is not recommended in the summer, so if in the warm season the stove is used for cooking food, then it is better to forget about the installation of water heating. The fact is that in summer the coolant from the system is drained, and with long heating of steel pipes, the metal quickly burns.

A brick oven for water heating a house may have a separate chamber in which the heat exchanger is located. The access of gases to such chambers is limited by the valve and is blocked for summer time. But in this case, the efficiency of heating is reduced, because the heat exchanger is already heated by the order of the cooled gas.

Comparison of the described furnaces

When it comes to how to make water heating from the stove, you need to take into account several features of this type of heating systems:

- The best option can be considered the purchase of factory-made stoves. In this case, the risk of malfunctions, for example, a leak in the heat exchanger is close to zero. The installation of the heating system, in principle, does not differ from conventional heating, the steps are the same - pipe demolition, installation and connection of radiators, heating regulators, installation of a circulation pump, expansion tank;

- However, it is better to leave the brick water heating furnaces for those who like experiments. Still, the above disadvantages are significant and can cause a lot of problems;

- for heating small rooms or irregular heating of the house, it is possible to advise conventional long-burning stoves, for example, T-stoves. The range of stoves "Teplodar" allows you to choose a model for any area of the house.

Summarizing

Water stove heating is quite real, although at first glance it sounds a bit strange. For a moderate fee, you can get all the benefits of water heating, even in a country house, while the cost of heating homes remains at an acceptable level.

If desired, you can even turn an ordinary brick oven into a kind of heating boiler. The proposed material will help to orient among the masses of furnaces of different types and choose the best option.

The video shows a simulation of a brick stove with the addition of a water circuit.