Water pump for heating: forced circulation of coolant

Most often, modern heating systems use special devices that allow the forced circulation of water. These are water pumps for heating and they are especially relevant if it is intended to provide buildings with a large area with heat.

The benefits of forced circulation

The movement of the coolant in heating systems can be carried out in a natural way or with the use of additional devices. In the first case, the liquid circulates due to the temperature difference, and in the second - due to the pumps connected to the electrical network.

The forced method has a number of undeniable advantages:

- There is no need for strict adherence to the rules for the location of pipelines.

- It is possible to adjust the temperature in individual rooms during operation of the system.

- In the presence of a circulation device, elements with a smaller diameter can be used.

- Economy at fuel consumption is ensured by automatic regulation.

Note! The main disadvantage is that the device for transferring coolant is dependent on power supply. In case of emergency on the power lines, the system will stop functioning.

Basic device types

Circulation pumps for heating systems may vary significantly, so their price may vary somewhat. Some models can be distinguished by high power, others - indicators of wear resistance or any other characteristics. However, all devices can be divided into two types.

Wet rotor designs

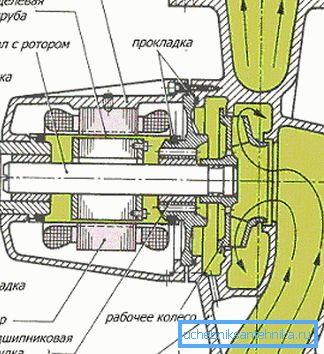

In such devices, the rotating part is located directly in the pumped medium. From the stator impeller is separated by a special glass, which is made of stainless steel. As for the rotor shaft, it can be made not only from metal, but also from ceramics.

The efficiency of this device for pumping fluid is about 50 percent, and this is normally enough. New models with a rotor immersed directly in the coolant are constructed with the support of the modular principle, when the blocks are installed in accordance with the necessary flow and size.

The impeller of this type of circulation pumps combines the advantages of radial and axial mechanisms. The bearings together with the rotor and the shaft form a single unit. At launch, such structures are capable of producing independent air removal.

Products with a dry rotor

These devices are characterized by higher efficiency, therefore, are more suitable for installation in systems where it is necessary to pump large volumes. Instrument motors do not come into contact with the process fluid. A characteristic feature is the presence of a special seal between the motor and the pump room.

When working between the sliding surfaces, a thin water film is formed, because in the heating system the fluid is under high pressure, when compared with the surrounding atmosphere. Such a membrane allows sealing when the main parts rotate.

Ring making is usually made from agglomerated carbon, stainless steel or ceramics.

If we talk about design features, then we can distinguish two subspecies of products, the cost of which will differ significantly.

- Console devices are made in the form of a separate structure, which has no connection with the body. The impeller and the motor shaft are connected through a special coupling.

- Monoblock analogs are a block that includes the engine and the body itself. In this version, the impeller is mounted on the shaft.

Note! To use products with a dry rotor for heating small buildings does not make sense. You can install them when creating a heating system in large cottages and other large buildings.

Installation

To install the device quite realistically with your own hands, since this process does not imply any complicated actions, although you will still need certain skills. Complete with the main device are always supplied sealing rings and the necessary parts.

Main provisions

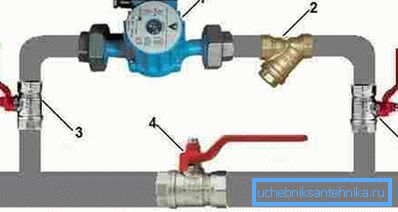

- The place for installation must be selected so that it is possible to additionally install the coarse filter. It will protect the device from the ingress of large particles of rust and other inclusions.

- After work, the impeller should be horizontal. If this is neglected, the circulation pump will make a noise during operation or cease to function altogether.

- During installation, nozzles should not be confused. As a rule, special arrows are placed on the body, which reflect the direction of movement of the working environment.

- Threaded connections must be sealed with a special tape or regular tow. The mating elements are necessarily separated by gaskets.

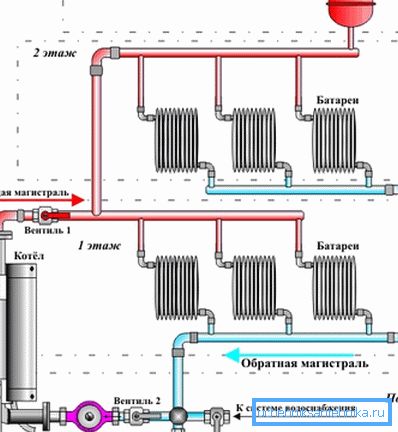

- Installation of the pump and shut-off valves is carried out directly on the bypass, which is necessary so that in emergency situations the coolant can pass through the central pipeline.

- Before starting the system, unscrew the screw on the cover. In this case air will be removed from the system.

Sequencing

When installing the pump, you must adhere to a specific plan to avoid difficult situations. Detailed instructions for performing operations are provided below.

It reflects the most significant moments.

- The first step is to prepare the heating system for the installation of the device.. To do this, completely removed the coolant. It is also desirable to clean the heating pipelines.

- Next, the pump itself is installed directly on the bypass valve.. When fixing the motor shaft, the box should be rotated with minimal effort. At the edges of the installed cranes.

- This is followed by inserting a stroke into the central pipeline.. During the work, special fittings or welding machine are used. A crane is also installed on the main pipe.

- Installation work is followed by connection to the electrical network.. All models operate from lines with a voltage of 220 volts.

- After performing the main work, the system is tested.. To do this, it is filled with coolant. If there are no leaks, and the circulation is normal, then the work was carried out qualitatively.

Attention! In order not to drain the fluid from the entire system, you can use valves. It is installed directly in front of the place where the device will be located.

Possible causes of failure

- Improper placement of the terminal and the main cable leads to serious malfunctions.

- The engine is not located horizontally, so there is an accumulation of air inside, which disables the device.

- Poor filtering device passes solid particles, in connection with the functioning of the product.

As a conclusion

Circulation pumps for water heating in modern heating systems are considered to be practically obligatory elements, since due to them the installation of pipelines is carried out taking into account aesthetic considerations. For more detailed acquaintance with the device it is recommended to watch the proposed video.