What are electric heating boilers: an overview

Let's start with the fact that electric heating boilers can radically differ from each other not only by technical parameters (power, size), but also by the principle of operation, that is, by the method of heating the heat carrier and its transportation.

Nevertheless, any of these units is excellently suited as a heating device, either for a country house (mansion) or an apartment in a high-rise building, or for a centralized boiler house serving several houses.

Let's see what these devices can be like in general, where it is best to use them, and also a themed video clip will be provided to your attention.

Differences in the method of heating the coolant

Heating element

- Units that have a tubular electric heater installed or TEN are called - TEN boilers and the liquid in them is heated using this device. As a rule, such installations are quite compact, they have an excellent design, and they are mounted on the wall.

- The main advantage of an electric heating boiler over gas, diesel and solid fuel is the absence of a chimney. The thing is that electricity has no combustion products, therefore, they do not need to take to the street. This advantage allows you to mount the unit in any convenient place of the room, without being tied to the wall that goes outside.

- Aluminum, steel or titanium housing;

- Filler (quartz sand);

- Spiral of nichrome;

- Contact rod in the filler;

- Sealant;

- Insulator (porcelain);

- The outer part of the contact rod.

Note. As a rule, TEN, which is installed on wall-mounted electric boilers for heating, has a zigzag shape. In addition, there may be two, and sometimes even three pieces per unit (depending on the power and the manufacturer’s project).

Electrodes

- Electrode heating electric boiler is fundamentally different from TENovogo by the method of heating the coolant (as a rule, it is distilled water with any additional liquids recommended by the manufacturer). Both those and other units operate from a variable network either at 220V or 380V (single-phase and two-phase) - everything depends on the power. But the price of both will be about the same, although the power consumption is changing.

- The frequency of the current in our electrical networks is 50 Hz, regardless of voltage, and this directly affects the heating of the coolant. The electrodes in the vessel through which the fluid moves change their polarity 50 times per second and this causes the coolant ions to change direction with the same frequency, that is, 50 times per second. This causes it to heat up.

- As you know, the current moves along the path of least resistance, which means that its movement lies within the distance between two electrodes. - this suggests that the ionization process is in no way dangerous for the consumer, to put it simply, it will not be electrically shocked. In case of leakage of fluid from the tank, the closed circuit between the electrodes is broken, therefore, the entire system is turned off, so that in such situations there is no fire hazard. This is the same as if you broke the spiral - the circuit opens and the device stops working.

Model overview

Tenovy models

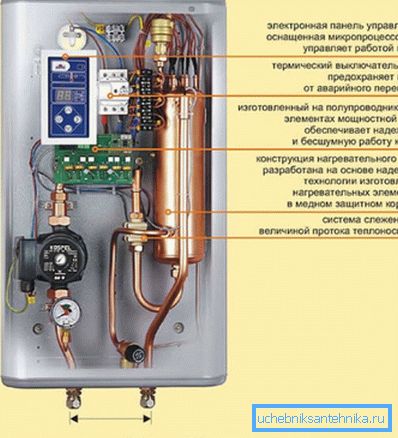

At present, electric heating boilers ROMSTAR are produced both in heating and electrode versions, only the second version has smaller dimensions and the prefix mini is attached to the name (we will also tell about them). Such a heating device consists of a metal case in which a heat exchanger is built in, switching elements and an electronic control and protection unit (power relays, temperature sensors, terminals, etc.).

The main part of the whole unit is a heat exchanger, which consists of electric heaters or heating elements, sealed in a vessel with two connections for water inlet and outlet. The upper nozzle serves to drain the heated coolant to the heating devices via a flow switch, and the lower one is connected to the return pipe.

Electronic control valves are designed to analyze and further process data that comes from the sensors in various operating modes. All other parts of the boiler, together with the control valves, are fixed inside the housing with bolts and screws.

The temperature range at ROMSTAR is in the range of 10-85? C, but if the water temperature rises to 90? C, then the circuit breaker will activate and the heating will stop. Given the characteristics of the manufacturer, the heaters here have increased reliability, since they are made of the latest materials. Also improved automation, which makes such boilers reliable and safe in operation.

| The number in the name REMSTAR | 3 | five | 7 | ten | 12 | 14 |

| Power, kWt) | 3 | five | 7 | ten | 12 | 14 |

| The volume of heated area (m3) | 75-90 | 125-150 | 175-210 | 250300 | 300-360 | 350-420 |

| The size of the heated area (m2) | thirty | 50 | 70 | 100 | 120 | 140 |

| Rated consumer power (kW) | 3 | five | 7 | ten | 12 | 14 |

| Mains voltage (V) | 220 | 380 | ||||

| Maximum current in phase (A) | 13.7 | 22.7 | 31,8 | 15.2 | 18.2 | 21.2 |

| Cross-section of copper wiring for power and ground (mm2) | 2.5 | four | four | 52.5 | 5.4 | 54 |

| Optimum liquid outlet temperature (? C) | 70 | |||||

| Maximum liquid outlet temperature (? C) | 85 | |||||

| Recommended heat carrier volume in the heating circuit | 120 | 200 | 280 | 400 | 480 | 560 |

| Heat carrier recommended by the manufacturer | Distilled or low-temperature water (does not freeze to -40? C), as well as liquids, which have a boiling point of at least 100? C and they are certified as a heat carrier | |||||

| Factory-recommended pumps from Grundfos | ALPHA 2 25/60, UPS 25/60 | |||||

| The diameter of the coupling, as well as the inlet and outlet nozzle (mm) | 20 | |||||

| Degree of protection against moisture | 1PX3 splashproof | |||||

| Dimensions (mm) | 572x270x105 | |||||

| Mass (kg) | 12 | 13.5 |

Note. In the room where the electric boiler is installed, there should not be explosive vapors and gases, as well as dust that can affect the operation of the boiler.

An excellent alternative to gas heating is the German ELOBLOCK electric boilers - they are reliable, ergonomic and compact. Installation of such units is very easy, they are silent in operation and, if necessary, simply change the mode settings.

The advantages of ELOBLOCK include microprocessor control of one key, built-in weather-dependent control, freeze protection, and the possibility of using the device for a floor heating system. In addition, the boiler can be controlled via an HDO signal or a down switch, where the settings indication is displayed on the LED display, an indirect heating boiler can be connected to the system.

And, of course, this is an excellent case design that can harmonize with almost any interior.

Models operating on a variable network of 220V / 50Hz have a power of 6 and 9 kW, and those that need 380 V / 50 Hz are represented by units with a capacity of 12, 14, 18, 21, 24 and 28 kW. The expansion tank here has a volume of 7 liters, the maximum water temperature is up to 85? C, and the operating pressure is from 0.8 bar to 3.0 bar, although it is recommended to maintain an optimal value of 1.0-2.0 bar.

Geometrical dimensions of the device according to the parameters height / width / depth 740x410x330 mm, with a mass of 34 kg.

The electric boiler for heating RUSNIT is produced by the Russian joint-stock company of the same name, which was formed on the basis of the Red Banner plant in Ryazan (the plant had previously collaborated with Roscosmos). Currently, JSC produces high-quality heating systems that use stainless steel heating elements, and the entire device is made of the most modern materials. The efficiency of real boilers reaches 93%, and the most powerful models are able to heat a room of up to 1000m2.

| RUNT marking | Voltage (V) | Power, kWt) | Area of the room (m2) | Efficiency (%) | Parameters W / W / H (mm) | Mass (kg) |

| 203 M | 220 | 3 | thirty | 93 | 485x194x138 | 9 |

| 204 M | 220 | four | 40 | 93 | 482x194x144 | 9 |

| 205 M | 220 | five | 50 | 93 | 505x305x205 | 12 |

| 206 M | 220/380 | 6 | 60 | 93 | 505x430x205 | 12 |

| 207 M | 220/380 | 7 | 70 | 93 | 505x430x205 | 12 |

| 208 M | 220/380 | eight | 60 | 93 | 505x430x205 | 12 |

| 209 M | 220/380 | 9 | 90 | 93 | 505x430x205 | 12 |

| 212 M | 380 | 12 | 120 | 93 | 530x240x370 | 18 |

| 215 M | 380 | 15 | 150 | 93 | 530x240x370 | nineteen |

| 218 M | 380 | 18 | 180 | 93 | 530x240x370 | nineteen |

| 221 M | 380 | 21 | 210 | 93 | 530x240x370 | nineteen |

| 224 M | 380 | 24 | 240 | 93 | 530x240x370 | 20 |

| 230 MP | 380 | thirty | 300 | 93 | 620x270x410 | 36 |

| 230 M | 380 | thirty | 300 | 93 | 620x270x410 | 25 |

| 236 MP | 380 | 36 | 360 | 93 | 620x270x410 | 36 |

| 236 M | 380 | 36 | 360 | 93 | 620x270x410 | 27 |

| 245 MP | 380 | 45 | 450 | 93 | 407x280x630 | 36 |

| 245 M | 380 | 45 | 450 | 93 | 407x280x630 | 26 |

| 270 M | 380 | 70 | 700 | 93 | 1045x500x280 | 60 |

| 2100 M | 380 | 99 | 970 | 93 | 1045x500x280 | 64 |

RUSNIT M

| RUNT marking | Voltage (V) | Power, kWt) | Area of the room (m2) | Efficiency (%) | Parameters W / W / H (mm) | Mass (kg) |

| 205 K | 220 | five | 50 | 93 | 505x305x205 | eleven |

| 206 K | 220/380 | 6 | 60 | 93 | 505x305x205 | 12 |

| 207 K | 220/380 | 7 | 70 | 93 | 460x240x600 | 12 |

| 208 R | 220/380 | 6 | 80 | 93 | 460x240x600 | 12 |

| 209 R | 220/380 | 9 | 90 | 93 | 505x305x205 | 12 |

RUSNIT COUNTRY

| RUNT marking | Voltage (V) | Power, kWt) | Area of the room (m2) | Efficiency (%) | Parameters W / W / H (mm) | Mass (kg) |

| 205 NM | 220 | five | 50 | 93 | 690x495x230 | 25 |

| 207 NM | 220/380 | 7 | 70 | 93 | 690x495x230 | 25 |

| 209 NM | 220/380 | 9 | 90 | 93 | 690x495x230 | 25 |

| 212 NM | 380 | 12 | 120 | 93 | 660x410x260 | 28 |

| 215 NM | 380 | 15 | 150 | 93 | 660x410x260 | 28 |

| 218 NM | 380 | 18 | 180 | 93 | 660x410x260 | 28 |

| 221 NM | 380 | 21 | 210 | 93 | 660x410x260 | 28 |

| 224 NM | 380 | 24 | 240 | 93 | 660x410x260 | 28 |

RUSNIT NM

For EVAN boilers, in addition to the Standard, there are also such classes as Economy, Comfort, Comfort RX, Lux and Professional - all of them differ in cost and power characteristics, but in more detail we will consider only Economy and Standard classes.

Such units are equipped with stainless steel heating elements, steel casing and electronic control fittings, there is double protection against overheating, relay switching and a block for connecting the circulation pump for the heating system. The working pressure is 0.8-3.0 bar, the recommended one is 1.0-2.0 bar, and the boiler efficiency reaches a bar of 93%.

| Marking EVAN EPO | Power, kWt) | Area of the room (m2) | Parameters for H / W / D | Voltage (V) |

| 2.5 | 2.5 | 25 | 565x270x220 | 220 |

| four | 4.0 | 40 | 565x270x220 | 220 |

| 6 | 6.0 | 60 | 565x270x220 | 220 |

| 7.5 | 7.5 | 75 | 565x270x220 | 220 |

| 9.45 | 5.5 | 95 | 565x270x220 | 220 |

| 12 | 12.0 | 120 | 565x270x220 | 380 |

| 15 | 15.0 | 150 | 565x270x220 | 380 |

| 18 | 18.0 | 180 | 565x270x220 | 380 |

| 24 | 24.0 | 240 | 565x270x220 | 380 |

| thirty | 30.0 | 300 | 565x270x220 | 380 |

Economy Class Features

| EVAN marking | Power, kWt) | Area of the room (m2) | Parameters for H / W / D | Voltage (V) |

| C1-3 | 3 | thirty | 650x250x180 | 220 |

| C1-5 | five | 50 | 650x225x180 | 220 |

| C1-6 | 6 | 60 | 650x225x180 | 220 |

| C1-7.5 | 7.5 | 750 | 650x225x180 | 220 |

| C1-7.5 | 7.5 | 750 | 650x225x180 | 380 |

| C1-9 | 9 | 90 | 650x225x180 | 220 |

| C1-9 | 9 | 90 | 650x225x180 | 380 |

| C1-12 | 12 | 120 | 650x225x180 | 380 |

| C1-15 | 15 | 150 | 650x225x180 | 380 |

| C1-18 | 18 | 180 | 650x225x180 | 380 |

| C1-24 | 24 | 240 | 650x225x180 | 380 |

| C1-30 | thirty | 300 | 650x225x180 | 380 |

Characteristics class Standard

Of course, it would be wrong not to mention the combined gas-electricity boilers - this is probably the most profitable combination of all possible options. And we will focus on the rather popular dual-circuit model Zhytomyr -3 KS-GV-010 CH / KE-4.5.

Such heating boilers combined electric and gas, as a rule, have several connection outlets, which allows you to mount a double heating circuit (floor heating - radiators), as well as heat the bath or pool. Having in the arsenal of two types of fuel, you can always choose the most profitable for you and do not interrupt the operation of the unit during a power outage.

Zhytomyr -3 KS-GV-010 CH / KE-4.5 is a single-phase floor-mounted double-circuit heating unit with a capacity of 10 kW for gas consumption and 4.5 kW for electricity consumption, and the optimum heating area will be 100m2 and 45m2 respectively.

Such electric-gas heating boilers have an efficiency of up to 95%, but not less than 90%, with a maximum supply temperature of 90? C, and the recommended mode is 60-80? C, like any convection gas unit.

It is noteworthy that such heaters are able to work on two energy carriers simultaneously, which increases power, and their mass is not more than 54 kg for single-circuit and not more than 58 kg for double-circuit options.

Electrode boilers

On a note! For direct-flow boilers of the electrode type it is strictly forbidden to use any petroleum products (oil, diesel, etc.) as a coolant, also those liquids that are not recommended by the heater manufacturer should not be used. The installation of any taps or shut-off valves between the supply pipe and the security group is strictly prohibited!

And now, as promised above, we will tell you about the PMSTAR MINI models, which are sold complete with a power unit and a thermostat for the room and, of course, with an operation manual. When installing the heating with your own hands, you need to install such a boiler in a strictly vertical position above the flow contour. But at the same time it should not be raised too high.

The cross section of the riser, as well as the cross section of the horizontal contour, must comply with the project, but the minimum diameter of the vertical will be 25 mm and more, and the height of the riser above the boiler fixed to the wall will be at least 2 m.

| Digital marking ROMSTAR MINI | 2 | 3 | five | 6 |

| Power, kWt) | 2 | 3 | five | 6 |

| The volume of heated area (m3) | 50-60 | 75-90 | 125-150 | 150-180 |

| The size of the heated area (m2) | 20 | thirty | 40 | 60 |

| Power consumption (kW) | 2 | 3 | five | 6 |

| Mains voltage (V) | 220 | |||

| Maximum current in phase (A) | 9.1 | 13.6 | 22.7 | 27.3 |

| Cross-section of copper wiring for power and ground (mm2) | 2.5 | four | ||

| The optimal volume of coolant in the heating circuit | 80 | 120 | 200 | 240 |

| Heat carrier recommended by the manufacturer | Distilled or low-temperature water (does not freeze to -40? C), as well as liquids, which have a boiling point of at least 100? C and they are certified as a heat carrier | |||

| Geometrical parameters of V / Sh / G (mm) | 400x100x70 | 650x100x70 | ||

| Cross section of the supply and return pipe (MM) | 25 | |||

| Mass (kg) | 3 | five | ||

| Electrical protection class | one | |||

| Degree of protection against moisture | 1PX3 (splash protection) |

Currently, the company GALAN launched the production of the film boiler GALAX, which is made using screen printing technology and came to replace the tubular heaters that we are used to.

According to manufacturers, the power consumption is reduced by 25% here and at the same time the coolant itself does not come into contact with the heater and power is distributed evenly across the entire body of the device, which removes the hydraulic resistance of the liquid. To give a concrete assessment of the quality of this unit at the moment is not entirely simple, since it is used relatively recently.

Conclusion

When choosing an electric boiler should be repelled from the estimated heated area and the amount of fluid in the system. Also in country houses, you may need a voltage regulator to remove its drops, which are especially noticeable in the evening.