What are fireplaces with water heating

Both for large mansions and cottages, and for small private houses on a country plot it is very convenient and advantageous to use heating fireplaces with a water circuit. In addition to the heating boiler, you also get an aesthetic addition to the interior design of the room.

It is noteworthy that such heaters can be used at any time of the year, without making reference to a common circuit - you can always warm yourself at the hearth, if it works in an autonomous mode, without heating the heating medium. Below we will conduct a short review of such units, find out about the method of their installation and, in addition, see a short video clip on this topic.

Thermocamps

Note. Names such as fireplaces with a water circuit or with a water jacket, thermo fireplaces - all this refers to the topic we are discussing and has the same meaning.

Principle of the device

- By and large, any fireplace is a modification of the furnace and any stove-setter or even a craftsman who is familiar with the foundation of brickwork and has a drawing before his eyes can build it with his own hands.. After all, this design is nothing more than an open-type firebox with a simplified chimney, but if there is a water jacket on top, then the firebox is, of course, closed type.

- If an open-type firebox, the heat from it immediately goes into the room, but at the same time half of this energy simply flies into the pipe in the truest sense of the expression. Therefore, the presence of a water boiler requires a certain sealing (furnace door) and maximum delay of the heat produced inside the structure. If you have calculated the design correctly, then its efficiency can reach up to 85%, and this is already an indicator of some models of solid fuel, diesel, electric and household gas heating boilers!

- But in the fireplace, the water boiler is not of the usual type, for the most part it is a set of interconnected metal tubes located along the walls and on the ceiling of the firebox. And, of course, they are in the middle of a double metal casing, that is, outside the zone of action of an open flame. In this case, firewood, briquettes, pallets, as well as coal and charcoal can be used as fuel.

Water jacket

In order to install a tubular type system in your design, you need to prepare a footprint for this. And it, as a rule, is made of sheet steel 4-5 mm thick or of cast iron, only here the thickness should be increased to 7-8 mm.

From the outside, such a body is covered with heat-resistant paint, or they are covered with decorative brick, but, nevertheless, the coating will not be superfluous, even if the metal is covered with a decorative finish.

The water jacket can be either from the metal sheets themselves or from the system of interconnected tubes, as in the photo above. This will not have a significant effect on efficiency, but the operational life of a tubular system, closed by metal, will be at least twice as high due to a decrease in the likelihood of wall burn-through.

Given that the metal is an excellent conductor of heat, the fact that the pipes will be fenced off from an open flame by a steel or cast-iron partition will not affect the heating of the water in the system. Unless very small share of efficiency will be spent on heating of the partition itself.

Note. Hot air is formed in the metal casing and if it is taken to a room, having equipped special channels for this, then radiators will not be needed at all in the room where the fireplace will be installed.

Pyrolysis fireplaces

Note. First of all, let's look at the terminology and understand that pyrolysis is the thermal decomposition of organic matter into lighter molecules, that is, in simple terms, the smoke resulting from the combustion of organic substances is just the product of the pyrolysis process.

And now let's see what pyrolysis can give in heating structures.

- First, the pyrolysis product is an organic matter that has not yet been burned to the end, therefore, they can be burned to obtain additional thermal energy.

- And secondly, smoke is a secondary heat and instead of diverting it into the chimney, you can use this energy, thereby increasing the efficiency of the entire heater.

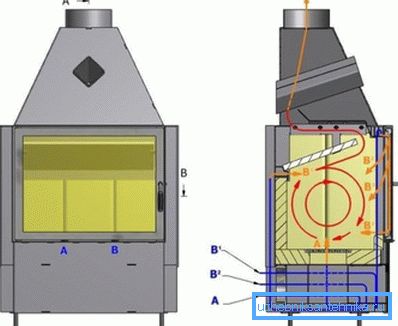

Pay attention to the upper figure - there you see the gas generator insert in the section, more precisely, there are two fireboxes:

- there is a room with limited air access for laying and burning of firewood;

- and on top of the camera the combustion of pyrolysis products (smoke).

For ignition, air enters the lower chamber through an ashpit (A), it also enters to blow glass (B1), but channel B2 is designed to bring hot air into the pyrolysis chamber, where the final fuel burns out.

The main advantage of the gas fireplace, of course, is a very high efficiency - sometimes it can catch up with the 100 percent mark and this is not fiction, but reality. Air is supplied to the gas generator chamber from above.

That is why in solid fuel boilers often the firebox is located at the top, and the afterburner chamber from the bottom - this greatly simplifies the design. In order to preserve the efficiency of burning firewood, the firebox is necessarily laid on fireclay bricks, and only then decorated. Although it is quite possible to purchase a decorative refractory brick.

Some samples

Metal PL-190, made in Poland from sheet steel 4-6 mm (depending on the construction site) is an angular type of fireplace with a water jacket and side opening of the door. If the main components are made of heat-resistant steel, then the door frames, stoppers and the grate are made of cast iron. The diameter of the chimney pipe here is 180 mm, and CO emission is 0.4%, at an outlet temperature of C16? C.

Air intake from this structure is carried out from the street side, and heating is carried out by firewood, briquettes and pellets in a continuous combustion mode. The working pressure in the water circuit with a volume of 32 l. The instruction provides for up to 8 bar, the nominal power is 8 W, the efficiency is 75%. The unit is sufficient for heating an area of 100 m2.

Metal PL-190, made in Poland from sheet steel 4-6 mm (depending on the construction site) is a direct type of fireplace with a water jacket and side opening of the door. If the main components are made of heat-resistant steel, then the door frames, stoppers and the grate are made of cast iron. The diameter of the chimney here is 180 mm, and the CO emission is 0.4%, at an outlet temperature of C16? C.

Air intake from this structure is carried out from the street side, and heating is carried out by firewood. Briquettes and pellets in a continuous combustion mode. The working pressure in the water circuit with a volume of 31-64 l. The instruction provides for up to 8 bar, nominal power 12, 15, 19 W, efficiency 75%. The unit is enough to heat an area of 200 m2.

PL-210 ECO is very similar in appearance and production to its counterparts, only the gas generator principle of combustion radically changes its performance. So, the diameter of the chimney is already 200 mm, CO emission is 0.11%, and the average outlet gas temperature is already 268? and an efficiency of 78%. Of course, its price is almost twice as high, but there is a huge fuel economy.

Conclusion

By installing a fireplace with water heating in your home, you will find not just a source of heat, but a cozy place to relax in a cold or even cool season. In addition, you can not only buy it, but add it yourself using the principles mentioned above. Successes!