What is the act of hydraulic testing of the heating system

Any heat supply system is an engineering structure, allowing to observe and maintain the specified temperature parameters in the cold period of the year. It is not necessary, however, to think that it can function smoothly without various planned preventive measures.

One of the most significant are hydraulic tests. With their help, it is possible to find the most dangerous parts of the system that can fail at the most inopportune moment.

Hydraulic testing of the heating system is a set of measures that should show how the pipelines, their connections, and also the heating equipment will operate during operation. You get the opportunity to immediately detect defects and eliminate them.

When it is necessary to carry out these works

Measures related to checking the heating circuit for tightness must be performed in the following cases:

- during the preparation for the heating season;

- after replacing parts of the system;

- after the repair of heating devices.

Construction companies are checking when the object is put into operation. The test procedure makes it possible to confirm the tightness of the circuit.

The procedure consists of the following stages:

- Air or water is supplied to the pipelines with a certain pressure using special equipment.

- Inspection and detection of defects in the heating circuit.

- The revealed violations are eliminated.

Tip: Currently, modern heating systems can be checked using a minimum number of people. This is especially true of autonomous heating in an apartment or private house, where it can be done independently.

It is better, of course, when at the time of start-up there will be one person in each room. In this case, defects can be noticed before a large part of the coolant flows out.

Rules of work

- There is a specially designed SNiP, which describes the rules for conducting such work.. From it you can learn about the intricacies and details of the process.

- It also has a typical instruction for holding these events.

- The technological schemes contained in the SNiP take into account the peculiarities of the work, taking into account safety engineering and the necessary equipment.. We recommend that any hydraulic test of the heating system is carried out in accordance with such a document.

Tip: flush the heating system before hydraulic testing.

- You can use any method for this, the main thing is to remove scale and deposits from the inner walls of pipes.. In particular, use special solutions and a compressor. Deposits can be oxides of various materials, including iron and calcium. We recommend flushing 1 time in 5 years, which will make the work of the heating system of high quality and reliable.

Otherwise, due to the above-described deposits, the efficiency of heat supply will decrease and you will have to spend more on the acquisition of energy carriers, the price of which is now quite high. This happens due to the reduction of the cross-section of pipelines and poor circulation of the coolant.

Perform crimping

If the work should be carried out in an apartment building, the responsibility for the prevention of these engineering networks is assigned to the organizations operating the buildings. Previously, they were called housing office, now they can be different, but the essence remains the same.

All activities should be carried out only by specially trained personnel using the necessary equipment. It is not necessary to shift their functions onto themselves; this will not lead to anything good. You can do pressure testing with your own hands only on an individual heating system.

The process looks like this:

- If the system is empty, it must be filled with water through the return pipe. By installing the valves at the highest points, it will be possible to bleed the air easily. They should be shut off when coolant begins to flow through them.

- After finding the defect, water from the system is removed through the drain valve.

- The pressure pump is connected to the control unit.

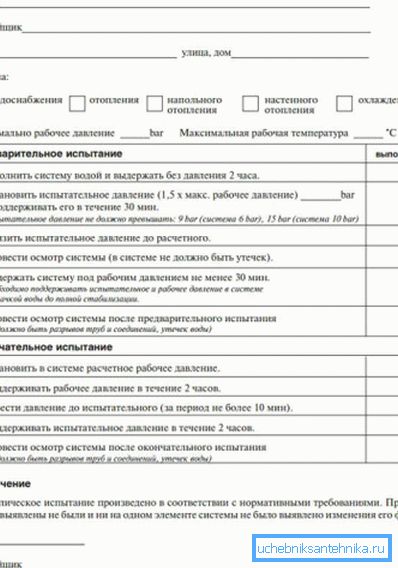

- The person responsible for carrying out these works fills out the appropriate form during the crimping process.

After completion of the work, an act of hydrostatic testing of heating and heating systems is drawn up. Indicates the strength of pipelines and different nodes of the scheme. Thanks to the act, it is possible to understand whether the heating system is suitable for further operation.

Conducting an inspection

Pressure testing of the heating system should be carried out with a pressure 1.5 times higher than the working pressure. Consider the process in more detail:

| The necessary conditions |

|

| First stage | The pressure in the heating system must rise in a cascade, at least two, until it reaches the set value. It is recommended to do this for half an hour, increasing every 10 minutes. The next 30 minutes you need to keep the pressure at 0.6 atm and above. |

| Second phase | The pressure should not fall below 0.2 atm. If a leak is detected in flanged or threaded connections, they can be tightened. When the defect cannot be fixed, the connection must be replaced. |

Conclusion

Hydraulic tests have great differences between central and autonomous heating systems. If in the latter case they can be carried out independently, in the first case only specialists should do it. The quality of the events will depend on the work of heating the building in the cold.

Video in the article will provide an opportunity to find additional information on the above topic.