What is the scheme of the heating system: subtleties

In multi-storey and single-storey industrial, industrial, public, and residential buildings, heating systems may vary greatly in their distribution and efficiency.

So, such systems can be:

- open and closed;

- dependent and independent;

- one-pipe and two-pipe.

This can greatly affect the final result when the room is heated. We will now pay attention to such differences, assess their advantages and disadvantages, and also show you a video clip on this topic.

Open

Principle of operation

Note. The main distinguishing feature of an open system from a closed one is an open-type expansion tank from which water evaporates. In addition, such contours are independent.

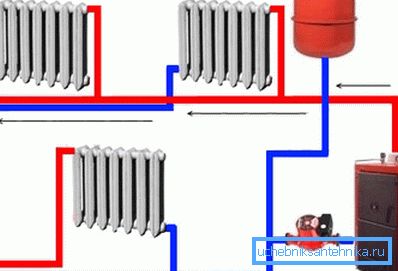

Open heating systems are independent, as the coolant circulates around the circuit as a result of natural pressure, without the use of a circulation pump. As a rule, in such situations solid fuel boilers, including gas generators, as well as stoves and fireplaces with a water jacket (tanks for heating water) can be used as a heater.

By the number of circuits, the scheme can be both single-pipe and two-pipe, but it is necessary to observe the slope when installing 0.01% of the initial coolant supply point. Since it is rather difficult to make such calculations, it is possible to proceed from the calculations of a slope of 8-10 mm per meter linear.

For normal operation of such a contour, the expansion tank must be above the horizontal coolant supply pipe in order to create pillar pressure. That is, hot water from the boiler during expansion enters the circuit.

But when the pressure exceeds the norm, it is simply dumped into the expansion tank, and when the coolant cools, as a result of column pressure, it returns back to the circuit. Such containers in private homes, as a rule, are installed in the attic.

Water circulation in such systems is rather slow, but this allows for uniform heating of pipes, which should be in such cases at least 40 mm in diameter. For this reason, such contours are most often made of steel, although they can also be made of polypropylene.

But the instruction does not interfere at all in the installation of an auxiliary pump in an independent open-type system to increase efficiency. As you can see in the top photo, on the main pipe, between the stroke for the pump there is a shut-off valve.

It is shut off, and the water begins to move through the circulation pump, and when an emergency light cut-off happens, the main tube opens and the stroke overlaps. Increasing the rate of circulation of the coolant significantly affects the efficiency of space heating.

Benefits

- The main advantage of a single-pipe or two-pipe open type system is its complete independence from third-party energy carriers. (Power lines, diesel or carburetor electric generator).

- Installation of open systems does not require special knowledge, as well as a license or admission when installing and connecting a gas or electric boiler.

- Solid fuel boilers or stoves, as a rule, unpretentious in the use of fuel - In addition to coal and firewood, it can be any organic materials in a dry state.

disadvantages

- The water in the expansion tank may freeze, so it must be warmed, but antifreeze must be added so that the liquid does not freeze is strictly prohibited.

- When air plugs are formed in these places, the pipes undergo corrosion, since natural pressure is not able to push the air through. To eliminate the plugs, you need to pump water into the circuit until all the air is out.

- Low efficiency.

Closed

Operating principle

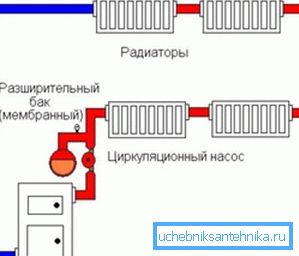

Note. Closed heating systems are dependent, so the circulation of coolant here is possible only with the help of a circulating pump that runs on electricity, therefore, depends on a third-party energy source (power lines, diesel or carburetor generator).

The systems of the closed type in most cases operate from gas, electric, diesel and solid fuel heating boilers and are directly dependent on electricity. Despite what kind of fuel the boiler itself operates on - the circulating pump operates exclusively with the help of electricity.

Nevertheless, such systems have gained universal approval and popularity due to high efficiency and reliability, as well as an automatic control method - in emergency situations on a power transmission line, a diesel or carburetor generator can be a source of electricity.

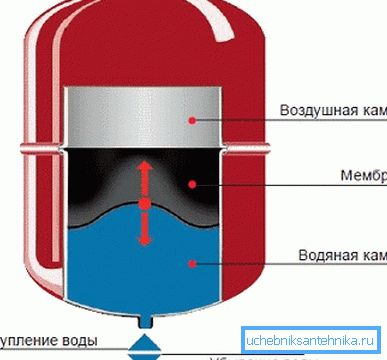

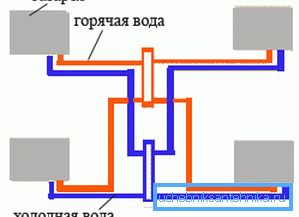

Such a system works on the principle of deaeration or automatic adjustment of the supported pressure using a special, hermetically sealed expansion tank. This capacity consists of two sectors, separated by a membrane of heat-resistant rubber.

In one compartment there is air or nitrogen (if the injection was made by the manufacturer), and in the second compartment, coolant flows through the safety valve if its pressure exceeds a predetermined threshold. When the coolant cools, the pressure in the system drops and the gas squeezes the liquid accumulated there from the reservoir back into the circuit.

Benefits

- The expansion tank in such systems can be installed anywhere (above, at or below the heating circuit) - in any case, an electric pump is responsible for circulating the fluid.

- No need to control the volume of coolant in the system (automatically adjusted).

- Antifreeze can be used to reverse the possibility of defrosting the system.

- For heating the circuit, you can use backup boilers, for example, in addition to the main gas boiler to install another solid fuel or electric unit. Also, all these heaters can work together as a group.

- All system parameters are automatically adjusted, therefore, it can be left unattended for a long period by setting the mode you need.

disadvantages

- Such systems have a higher cost of installation and equipment.

- Dependence on electricity.

Dual circuit

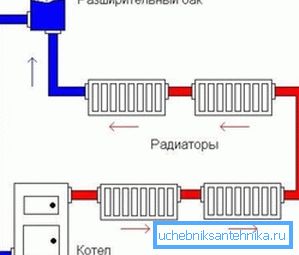

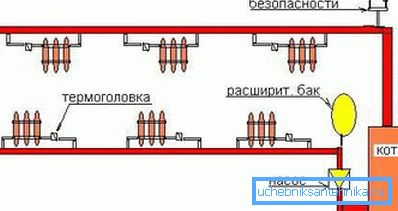

Two-pipe wiring diagrams of heating systems at the moment can be called the most common for the private sector, as they allow you to maintain a uniform temperature of radiators throughout the house. Adjustment of each individual device is performed using a thermostat or a conventional valve, which reduces the flow of coolant into the battery.

The essence of the work of the two-pipe heating circuit is as follows:

- heat carrier from the heater enters the supply pipe;

- where alternately is distributed on radiators;

- and after passing the fluid through the sections of the device, it enters already in the return pipe, through which it is fed back to the boiler.

The expansion tank in such cases can be either open or closed - it all depends on the type of system.

The great advantage of the two-pipe system is that the coolant is practically not cooled throughout the entire flow. That is, its temperature remains the same along the entire length of the pipe, as the cooled liquid enters a completely different pipe.

The feed is ringed on the last radiator, where it can switch to return either by the same pipe or through the battery, which practically has no difference - it just depends on the ease of installation.

Single tube circuit

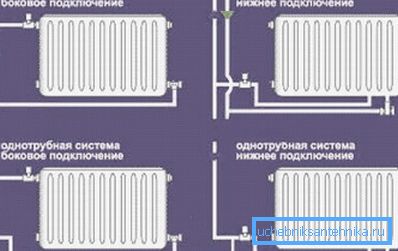

One-pipe installation of heating systems are less efficient, but they are much cheaper. Consequently, they can often be found in high-rise buildings of the Soviet era.

In this case, the flow of coolant here can be carried out both from below and from above, for example, almost all the Khrushchev houses (the largest number of buildings of the Soviet period) have the upper flow, but in brezhnevka you can often meet the flow of coolant from the bottom up. Often, in houses equipped with a lower supply, as practice shows, there are problems with heating.

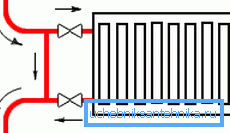

The essence of the one-pipe system is very simple and consists in the following: from the CHP plant, the central boiler house, the heat distribution point (TP) or from the boiler hot coolant is fed, which is alternately distributed to the radiators.

Only after passing through the sections, the cooled liquid is not discharged into the return tube, but gets there, from where it came. It turns out that the farther the radiator is from the beginning of the feed according to its serial number, the colder it will be the coolant.

Ideal for a single-loop system, it is three or four radiators per pipe — with more heat loss, they become tangible. To reduce the loss of heat energy, a bypass is installed in front of the radiator - a pipe bridge, through which part of the hot liquid is returned, without getting into the battery section. This is possible due to the difference in cross section (the bypass is thinner than the main).

Conclusion

You can (if you have certain skills) to collect with your own hands any of the above heating schemes. The most important thing is to correctly calculate the power of the boiler and heating devices relative to the total heated area.