What pipes are better for a warm floor - the advice of

Heated floors are the key to comfort and a cozy atmosphere in every home. Such a system can be both an additional and the main source of heating in the room. However, in order to ensure a really long service life of the insulated flooring, it is necessary to take into account all the details of its installation. And at the same time, the choice of pipes is a very important factor.

Requirements that quality pipes must meet

So, consider how to choose a pipe for a warm floor.

Regardless of the material you choose, the piping system must comply with the following parameters:

- Durability. The product should not be destroyed under the influence of temperature differences, as well as bacteriological or chemical loads. Ideally, with all the features of installation, the service life of metal-polymer and polymer pipes is not less than 50 years.

- Reliable tightness and insulation, which protects the heating system from oxidation.

- Elasticity. Must bend by hand and be resistant to bending, that is, do not give cracks and do not break. Copper, polyurethane, metal-plastic, polybutane, polypropylene and steel elements meet these requirements. Modern standards prohibit the use of cast-iron pipes for floor heating systems.

Note! Experts recommend to purchase products for the installation of heat-insulated floor only from trusted manufacturers. In case of defects, you will be able to receive compensation.

Types of pipes used for installing underfloor heating

To determine which pipe to use for underfloor heating, let's compare the characteristics of all the options on the market today:

| View | Specifications |

| Metal plastic | These types are made from polyethylene and aluminum, and have the following characteristics:

|

| Polypropylene |

|

| Polyethylene (PE) | They are more preferable than the previous form, but are quite easily damaged, and therefore require very careful handling. Such pipes do not hold the shape as a result of bending, therefore they require the use of a large number of fasteners. Able to withstand temperatures up to 120 degrees Celsius. |

| Copper and corrugated. | They are very expensive options, but they are the most durable and meet all installation requirements. They are characterized by the smallest bending radius, due to which they occupy the leading position in the modern market. The minimum service life is 50 years. They are able to withstand the temperature of the carrier up to 300 degrees Celsius at pressures up to 400 atmospheres. Such products are not afraid of corrosion, they can not spoil the rodents, they have high heat transfer and are impermeable to gases. At the same time they can not be connected with any accessories, except the one that is made of brass. |

Summarizing all the above, it is easy to determine from which pipes it is better to make a warm floor. Naturally, from copper. However, the high price of both the pipes themselves and the work associated with their installation scares most potential buyers. It is also very difficult to do it yourself.

Therefore, much more common are metal-plastic analogues, low cost and ease of installation which provided them with high popularity. Installation of such systems is very simple and is performed using fittings without welding.

Tip! Air has a negative effect on the reinforcement assemblies of the system, significantly reducing the service life. Therefore, you should use products where there is an “oxygen layer”.

You may be interested to know which pipes are used for underfloor heating abroad. Plastic products without aluminum interlayers are most commonly used there. They are very cheap, even in terms of quality, and inferior to both aluminum and metal-plastic counterparts.

How to calculate the required number of pipes

It is necessary to carry out the purchase of material for arranging the system of underfloor heating only after all the necessary calculations have been made. Therefore, consider how to calculate the pipe on the warm floor.

The instruction is not particularly complex:

- Take a sheet of paper (preferably millimeter) and transfer to it the size of the room in scale.

- Apply to the scheme large pieces of furniture, because under the furniture warm floors do not fit.

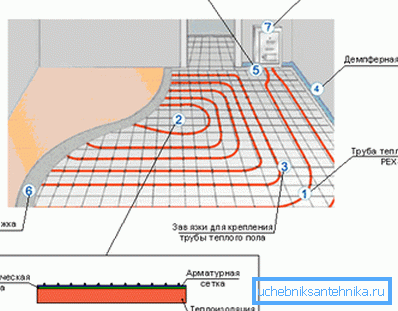

- Pipe consumption will directly depend on which scheme you choose.. The most popular are two mounting options: a snake and a spiral.

Note! The spiral stacking pattern is more complicated, but allows you to warm up the room evenly. The floor warms up around the perimeter: from the walls to the center. In addition, this scheme does not imply sharp bends of the pipe.

- Perform calculations based on the resulting scheme.. At the same time, consider that the distance of the first pipe from the wall should be at least 20 cm. The distance between adjacent pipes should be at least 35 cm.

Note! The length of one circuit should be no more than 60 meters. Therefore, if a room has a higher consumption, it is necessary to “split” the system into several independent parts.

Conclusion

Above, we looked at which pipe for underfloor heating is better and figured out how to correctly calculate the number of pipes for arranging underfloor heating. Pay special attention to the installation instructions for such floors.

For example, if the electric floor heating cables should be fixed as rigidly as possible, then this method is unacceptable for a water floor. The pipes must be laid in such a way that freedom of fastening remains, because they tend to expand under the influence of high temperature.

From the video in this article you will learn more additional information on how to choose pipes for underfloor heating.