Which pipes to use for a warm water floor: a review of

Modern innovations in the construction market allow you to make apartments or houses much more comfortable. And especially here water systems of warm floors stand out, which are assembled from various materials. And, as a rule, in such a case the most difficult moments for an inexperienced person are the calculation of the pipe for a warm water floor and the choice of its type.

In this article we will understand these issues, and also consider in brief how such structures are mounted with their own hands.

Let's start with the most important point.

Types of pipes

For convenience, the characteristics and types of pipes are presented in the comparative table:

| Product type | Special features |

| 1. Copper. | In principle, it is an excellent material, because copper is long, does not rust and has good strength. In the case of a mechanical load, the trunk will bend more likely than holes or cracks will appear in it. In Europe, it is the most popular type of material for the manufacture of such structures. But the most important advantage of copper is an excellent level of thermal conductivity. And this means that your floors will warm up as quickly as possible. As for the shortcomings, in this case it is probably one - this is a rather high price of copper “tracks”. |

| 2. Metal-plastic. | A great option for an average budget. The product is a trunk of several layers - plastic on top, and aluminum inside (by the way, this metal expands slightly when heated). Such a structure allows the warm floor to be strong enough and not to “overgrow” from the inside with various growths. |

| 3. Polypropylene. | Such water pipes for warm floors are rarely used, because they do not bend very well. In addition, since there is no metal in their structure, the heat exchange processes here are not too fast. That is, simply speaking, the heating system made of polypropylene will not be very effective. |

| 4. Products made of cross-linked polypropylene (PEX-pipe). | Differ in low cost, good level of heat conductivity and long service life. The disadvantages include the fact that it is rather difficult to install polypropylene, because if there is no instantaneous rigid fixation, it will immediately bend up. |

So, if we talk about which pipes to use for a warm water floor, it turns out that the “golden mean” between price and quality is metal-plastic products.

And besides, metalplastic is laid quite easily - the lines are flexible and durable. How such bays will be rolled out - so they will lie, without any inverse extensions.

Pay attention to the fact that, despite the presence of metal in the structure of products, they still need to be protected as much as possible when pouring the floor or drilling it with a perforator. Solid particles of liquid concrete can damage metal-plastic so that cracks will appear in it, and the drill will quietly pass through aluminum altogether.

Therefore, pouring the screed, try not to step on the “tracks”, and if you plan to drill the floor, remember the location of the heating system lines.

We have approximately decided on which pipes are better for using a warm water floor with an average budget.

Let's now consider how to calculate the desired footage of the system.

The layout of the highway and the calculation of footage

In fact, making a plan is a simple process.

Here it is necessary to act something like this:

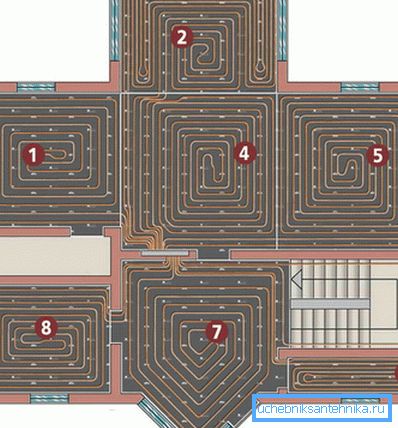

- We make a plan of the room on a scale where we mark the places where the furniture will stand. Where it will be located - the system does not need to be pulled, because there is no point in heating, for example, a cabinet - no, you will agree.

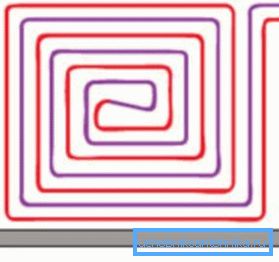

- Draw the layout of the structure. It is best to plan it this way - from the point of supplying hot water the route is pulled (as if in a spiral) to the center of the room. And then from the center of the line depart to the point of discharge. This arrangement gives a more efficient and uniform heating of the room.

- Starting from the pattern, we calculate the required footage of the metal-plastic bay.

Pay attention to the fact that it is not recommended to make a “route” from the contour more than 60 meters. If the system has such a footage, the hot water will cool down pretty quickly, and this will affect the efficiency of heating.

As for the parameters, in most cases, products with a diameter ranging from 15 to 20 mm are optimally suitable. As you can see, the calculation of a water heated floor pipe is really quite a quick and simple matter.

But with the assembly, everything is not so simple - there are nuances. We will understand everything with a clear example.

Installation of heated floor

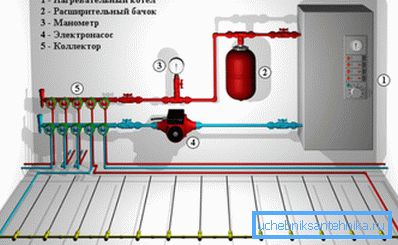

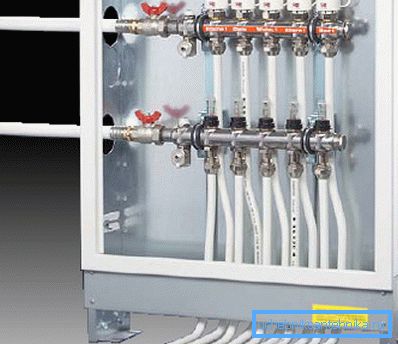

So, as a visual example, we take the organization of the system of metal with a layout on the principle of a spiral. Heating will be done in the apartment of a multi-storey building, as this is the most difficult case due to the need to insulate the ceiling (find out here what compression fittings for HDPE pipes are).

We proceed to the installation.

Preparatory work

At this stage, you should proceed according to the following scheme:

- We clear the floor plane of debris and foreign objects.

- Fill the roughing terrain of claydite-concrete.

- After the concrete dries, we fasten sheets of expanded polystyrene on top of it (the foam also fits, only it will need thick, which means that the total thickness of the floor will be greater in the end). Sheets are easiest to attach to special dowels with a wide cap.

- Lay the foil film on top of the insulation. If this is not done, the system will warm up not only the finishing layer of the floor, but also the overlap. That is, simply speaking, the area you need will warm up much more slowly.

This completes the preparation. We proceed to the next step.

Pipe laying

Here everything is performed in the following sequence:

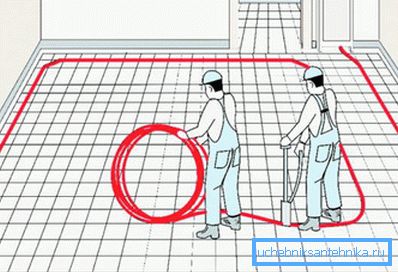

- We take the bay with metal-plastic, leave one end of the pipe near the hot water supply point and begin to unwind the track, laying it on the floor in a spiral, moving inwards, as it were, towards the center of the room. At the same time try to lay everything so that the distance between the parallel lines is about 15-20 cm.

- When you reach the center, make a reversal, as it were, and return along the same principle of a spiral to the point of withdrawal of the cooled water.

- Fix the pipes to the floor using fasteners and dowels.

- Connect the ends of the "piste" to the plumbing system.

Run water into the pipes (if the pressure is low, then you may need to install an additional pump). If there are no leaks, then you can fill the finish.

Pay attention only to the fact that when we considered the question of which pipes to choose for a water-heated floor, there was one important nuance regarding metal-plastic: when heated, such products expand a little. That is why you need to organize everything so that when the screed solidifies in the lines of the system in the first 5-6 hours there is hot water.

If it does not exist, the DSP will harden completely, and then, as it were, the pipe will have nowhere to expand.

Now let's summarize the review.

Conclusion

We figured out which pipes to choose for a warm water floor and why. We also considered all potential options in the comparative table, and also provided clear instructions for the installation scheme and principles for calculating the material (see also the article Pipes and Fittings of Cross-linked Polyethylene: technical characteristics and installation features).

We hope that you use the information obtained in practice. And if you want to know more useful information, then there is also an additional video in this article for you - view it.