Which radiators are better than aluminum or bimetallic ones:

When designing and installing heating systems, the question often arises as to which is better than aluminum or bimetal radiators. The question is not accidental, just as those and other modifications of the batteries are presented for sale and the unprepared buyer, when choosing them, remains to pay attention only to the cost and comments of the seller.

Criterias of choice

In fact, there are a number of criteria, given which you can choose the best option.

Among these criteria, we note the following:

- product price;

- energy efficiency (heat transfer, heat intensity and duration of heat release);

- attractive appearance;

- the complexity of the installation of their own hands without the involvement of specialists;

- the weight of the product and, as a consequence, the possibility of mounting on certain surfaces;

- adaptability to work with the coolant circulating in a centralized system;

- reliability and durability.

Having considered each modification for all the above items, you can find out what is best aluminum or bimetallic radiator. But, to begin with, we will determine the design features of this and other modifications.

Design features of heating devices

In order to find out what to choose from aluminum or bimetal radiators, you need to have a general idea about the design of these batteries.

- Aluminum radiators according to the method of manufacture are divided into three main types, namely, cast products with a monolithic section design, extruded products, in which prefabricated sections and combined products are used, which combine the advantages of previous modifications.

Battery sections are all-aluminum parts with hollow internal channels designed for the circulation of coolant. In the upper part of the sections and on the sides there are deflectors defining the direction of the flow of heated air.

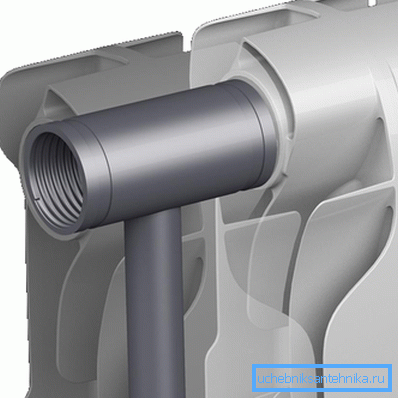

- Bimetallic radiators are designs that are externally similar to aluminum counterparts.. But there are a number of significant differences. The fact is that the channels intended for the circulation of the coolant are made of steel, more rarely copper tubes, and the cast alloy body is located above the tubular structure.

Despite the external similarity, bimetallic structures are more complex in the device and in production, which negatively affects their value. However, this disadvantage is compensated by other performance characteristics.

So, we found out that the price of aluminum products is more affordable than the cost of analogues made from two metals. But, in order to find out which radiators are better than aluminum or bimetal, other parameters need to be considered.

Coolant resistance

Instructions for the choice of heaters largely depends on their resistance to the heat transfer fluids used.

- High-quality aluminum radiators for a long time work in autonomous systems and at the same time do not need regular cleaning. But in conditions of centralized systems, where there are reagents and suspended solids in the composition of the coolant, aluminum batteries behave somewhat differently. First of all, more corrosive processes occur. In addition, due to the ingress of hard suspensions on the inner surface of aluminum structures, micro-strands appear over time. As a result, the channels for circulation of the coolant lose the original smoothness of the walls, and their capacity is significantly reduced.

- Bimetallic radiators are more resistant to the negative effects of reagents used in the composition of the coolant. This property is achieved through the use of steel tubular structure, directly through which water circulates. Steel, in contrast to softer non-ferrous metals, is not deformed when in contact with solid suspensions. Moreover, in the absence of oxygen inside the batteries, steel has little corrosive processes.

The conclusion can be made the following, if you do not know that radiators from bimetal or aluminum are better, choose what fits the type of heating system in use. That is, for autonomous systems it is possible to purchase one or the other category.

But for a centralized system, it is advisable to apply bimetallic modifications, which can be listened to longer without the need for regular operational maintenance.

Working pressure

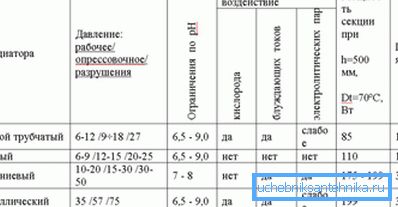

Choosing aluminum or bimetallic heating radiators we pay attention to the parameters of nominal and working pressure specified in the accompanying documentation.

- Batteries made of aluminum withstand pressure testing (short-term) pressure of up to 24 atmospheres, while working (long-term) pressure can be 16 atmospheres. For example, according to GOST, 10 atmospheres are supplied to urban heating systems in preparation for the heating season, and the operating pressure does not exceed 6 atmospheres.

- Bimetallic batteries differ from their aluminum counterparts in a narrower section of channels along which coolant circulates. But, despite the smaller section, such structures are designed for pressing pressure up to 40 atmospheres and working pressure up to 12 atmospheres.

What conclusion can be drawn from the above?

Choosing bimetallic radiators or aluminum radiators in accordance with the parameters of pressure, you can purchase any of these modifications, since their strength is sufficient for functioning both in autonomous and centralized systems.

Energy efficiency comparison

When deciding which radiator to choose bimetallic or aluminum, it is necessary to pay attention to the energy efficiency parameters. The term “energy efficiency” should be understood as a combination of such qualities as heat transfer, convection intensity, intensity of heating of the working surface, duration of heat release and, as a result, efficiency of operation of the heating system as a whole.

Consider how effective those and other batteries.

- Heating devices made of aluminum, are characterized by high heat transfer, which is explained by a large number of fins. The total area of the ribs and the total area of flat parts on average is up to 0.5 m ?. As a result, about 50% of the heat is released in the form of radiation, and another 50% is due to convection of heated air.

- Bimetallic type heaters due to the external aluminum surface are also characterized by a high degree of heat transfer. But, due to the small cross section of the tubular structure, they allow to reduce the volume of the circulating coolant. As a result, the use of such heating devices as part of an autonomous system contributes to maintaining a more economical mode of operation of the boiler.

Important: It is possible to significantly increase the energy efficiency of heating equipment by installing thermal heads on each battery (thermostats).

Features of the installation work

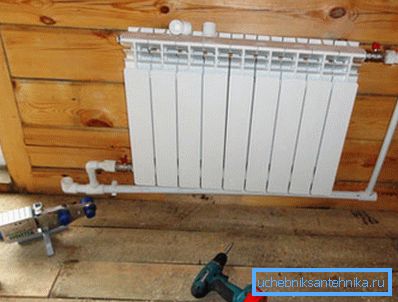

Choosing modern aluminum or bimetal radiators, it is mandatory to take into account the complexity of installation work and features of the subsequent operation of heating equipment.

There is a wide range of brackets for wall and floor mounting on the market, so there will be no problems with the installation of heating devices even if all the work is done by hand.

To connect to the pipeline, universal kits are used, consisting of two straight-through plugs and standard-sized plugs. Shut-off valves and thermostat, on both models is similar.

The only difference that you need to pay attention to when choosing a battery is the difference in weight.

Completely aluminum modifications are lighter than bimetallic counterparts. As a result, if the installation work is performed on old walls or on wooden walls, it is advisable to use all-aluminum devices. If you still decide to install bimetallic products in a room with weak walls, it is better to choose a floor layout.

Important: if during the installation process the battery needs to be shortened or vice versa increased by a couple of sections, the same modification of the radiator key is used.

Deciding which is better than an aluminum or bimetallic radiator, you can pay attention to the subsequent maintenance.

Are there any differences in favor of a device? The design of the one and the other modification looks very similar, namely, there are the same gaps intended for the discharge of heated air, there is a smooth front surface of the sections covered with a layer of powder paint.

As a result, it will not be difficult to wash off dirt from those and other heating devices. In addition, the specific location of the deflectors does not contribute to the deposition of dust, and therefore to carry out regular cleaning of dusty surfaces will not have any of those or other devices.

Conclusion

So, we reviewed the technical and operational characteristics and it remains to determine that the aluminum radiator or bimetallic radiator is better.

Based on the above observations, for arranging premises in apartment buildings, it is better to choose bimetallic structures, even though their price is somewhat higher. But for the arrangement of a country house we recommend to purchase all-aluminum devices.