Wilo circulation pumps for heating systems - a guarantee of

The circulation pump is an integral element of any heating system with forced circulation. The stability of the coolant circulation through the pipeline depends on this small device.

Pumps from the manufacturer WILO can rightly be considered among the best.

Why do we need a circulation pump

In some cases, you can completely do without this element when it comes to systems with natural circulation. In this case, the coolant moves through the pipes due to the pressure difference that occurs when water is heated in the boiler. The heat carrier expands during heating, part of it is simply squeezed up along the supply pipe, rising to the highest point, the water enters the radiators and, gradually cooling down, moves back to the boiler (see also the article Grundfos Circulation Pumps for home heating).

The only advantage of such an organization for heating homes can be called absolute independence from electricity. This is important, for example, when heating a country house or giving in a remote area. In addition, the absence of moving parts in the system extends its service life.

But it is better to install a circulation pump for Vilo heating before entering the boiler.

As for the benefits, the installation of such a device allows you to:

- to ensure stable circulation of the coolant through the pipes. Modern models are able to reduce the number of revolutions themselves, making the heating of the house not so strong. This quality is particularly useful in terms of financial savings;

- the pressure will not depend on the diameter of the pipe (in systems with natural circulation, it is better not to use small diameters);

- Installing a pump does not reduce the durability of the system as a whole; current models can work for 20-30 years.

Among the shortcomings, one can only note the small costs of electricity and noise. But the boiler is usually placed in a separate room, and the price of electricity is not too high to refuse the pump.

Classification of circulating pumps

As for the principle of operation, then all devices of this kind can be divided into 2 types:

- with a "wet" rotor;

- with a "dry" rotor.

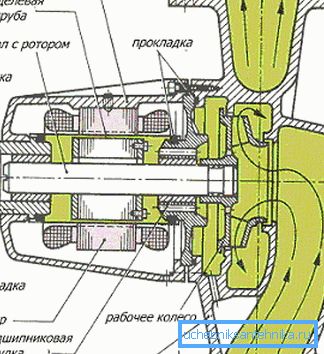

For heating a relatively small house, the options with a wet rotor are preferable. They got this name due to the fact that the rotor (the part that rotates) is placed directly in the pumped coolant.

Circulation pumps for Wilo heating of this type have the following features:

- almost completely silent;

Note! In small houses, it is sometimes not possible to move the boiler away from the living quarters, so noiselessness is an important advantage.

- lubrication is not needed - the rotor is in the water, so the coolant itself performs its role;

- for greater reliability, the rotor and stator chambers are separated by a durable stainless steel sleeve;

- The only and quite significant drawback is the low efficiency - about 50%.

Note! The "wet" pump must be installed so that its shaft is necessarily horizontal.

For a powerful system, it is better to use Wilo's “dry” circulation pump for heating. Unlike the “wet” counterpart, it has no contact with the coolant at all, and it is possible to achieve a high degree of tightness at the expense of the pumped liquid itself.

During operation, a thin film of liquid finally seals the microscopic gaps between the rotating surfaces. Over time, the O-rings grind off a little, but the problem is solved by the fact that they are spring-loaded and are simply shifted by the amount of wear, the main thing is that the grinding will occur evenly.

The main advantage of "dry" devices can be called the efficiency of more than 80%. And the disadvantages can be recorded high level of noise, so these pumps and are used mainly in high-power systems.

Read more about modern circulation pumps.

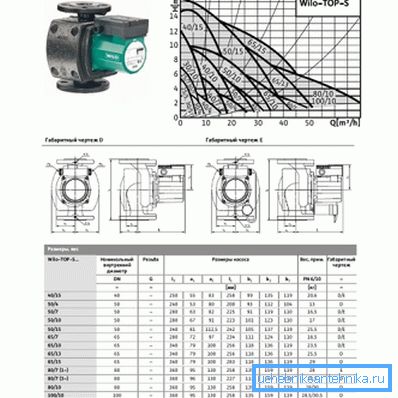

One of the main requirements for a modern heating system can be considered flexibility - that is, the ability to adjust its power in a wide range. Circulation pumps for heating systems Wilo is the best fit for this.

In the distant past, the circulation pumps were unregulated, that is, they did not know how to reset the rotor speed. This led to the fact that the heating system worked with approximately the same power at any time, even when there was no particular need for it.

Features of work of adjustable pumps

Nowadays, special attention is paid to energy saving issues, so unregulated devices are practically not installed in new heating systems.

The use of adjustable devices allows you to:

- change the rotor rotation frequency at any time, for example, to save energy at night, the device itself drops speed;

- specify any mode of operation manually; this is useful if the owner plans to leave the house for a couple of days. In this case, heating can be kept at a minimum.

Note! The German manufacturer Wilo produces models for working in very harsh environments. If the water content of lime is high, then you should pay attention to the model Wilo Star.

As a rule, the circulating pump for heating Wilo can operate in several modes:

- PP1 and PP2 - in this case, the pressure in the system will change, and the designations correspond to the working characteristic with maximum pressure (PP1) and minimum (PP2);

- CP1 and CP2 - in this case, the head remains unchanged, and the pump adjusts to the flow rate of the coolant, changing the number of revolutions of the rotor;

- modes of operation numbered I, II and III. The unit corresponds to the rotation frequency at the minimum operating characteristic, II and III - the rotation frequency at the average and maximum rotation frequency;

- There is a possibility to switch day / night modes.

Rules of placement and installation

If you can not invite experts, the installation can be done by hand.

You just need to remember a few simple installation rules:

- It is forbidden to place the pump at the outlet of the boiler - a hot coolant will reduce the service life of the device by several times. The optimum is the placement on the pipe section before entering the boiler;

- the arrow on the body indicates the direction of movement of the coolant, it should be directed to the boiler;

- when the pump is already installed and filled with water, air is removed from it;

- the pump is installed so that, if necessary, it can be quickly isolated from water. To do this, arrange a bypass and install shut-off valves.

Installation instructions for the pump are not particularly difficult, they use threaded connections, so that if necessary it can be quickly removed for repair or replaced. Before installing the boiler need to cut off valves. Also during installation, a check valve (with the exception of open systems) and a filter are installed.

Summarizing

A modern circulation pump is not only a device for creating the pressure required for circulating a heat transfer fluid, but also a kind of regulator of the heating system. The proposed material will allow you to get acquainted with the main features of the circulation pumps for heating and choose the best option for yourself.

The video shows the already installed Wilo compact and economical pump.