Working pressure in the heating system: we study the work of

What is the working pressure in the heating system of an apartment building considered to be the norm? What could be its maximum value? What parameters are better to set for the autonomous system? This article is about pressure and its effect on the operation of heating systems.

How things are arranged

Before finding out what pressure in the heating system is considered regular, let's get acquainted with the design of these systems.

Autonomous systems

This category includes circuits with natural circulation (gravitational) and heating pumps equipped with circulation pumps.

In the first case, the coolant is driven by a change in density during heating: warmer masses are displaced from the boiler to the upper part of the circuit with colder ones and, passing through radiators, give them excess heat. The head created by the expansion is extremely small and is usually measured in tenths of a meter; accordingly, the circulation does not have high speed.

In the second case, the coolant causes the low-power pump to move. It creates a pressure of one to six to eight meters, which dramatically accelerates the movement of water or water-glycol mixture in the circuit.

Reference: the meter of pressure corresponds to a pressure of 0.1 kgf / cm2 (1/10 of the atmosphere).

Autonomous heating systems are divided on one more basis: they can be open and closed.

- An open circuit communicates with atmospheric air through an open expansion tank.. Accordingly, the water pressure in the heating system corresponds to the height of the water column above the measuring point. If the water level in the expansion tank is 3 meters above the filling level, the pressure in the filling will be 0.3 atmospheres.

- The closed circuit with the atmosphere is not reported, which raises a number of problems with compensation for the expansion of the coolant during heating. To solve them, a membrane-type expansion tank is used - a tank, part of which volume is occupied by air separated from water by an elastic rubber membrane. In addition, the system is equipped with a safety valve: it resets the excess coolant when the tank is full.

For a closed heating system, there are two pressure related parameters.

- Charging pressure of the expansion tank heating. At room temperature, water or antifreeze, it is set equal to the hydrostatic pressure in the circuit.

Note: the hydrostatic pressure in the heating system of a private house again corresponds to the height of the water column and is taken equal to 10% of its height in meters.

- The relief pressure of the safety valve. It is usually set at 2.5 kgf / cm2.

The current static pressure in the heating system during its operation is determined by both the amount of water in it and its temperature. When heated, the gauge for obvious reasons begins to show large values.

CO

How does the central heating system work?

The heated heating plant or boiler water enters the house through the heating line. On the reverse thread, it comes back, giving off some heat. The water in the circuit is driven by the differential pressure between the threads.

The temperature of the water in the supply pipe depends on the current street and is associated with it, the so-called temperature schedule. Here is an example of such a schedule.

| Street temperature, C | Temperature of supply pipe, С |

| +eight | 53.2 |

| 0 | 72.4 |

| -five | 83.9 |

| -ten | 95.3 |

| -15 | 106.5 |

| -20 | 117.5 |

| -25 | 128 |

| -thirty | 139.3 |

| -35 | 150 |

The temperature of the return pipeline is also strictly regulated and at the maximum flow rate must be equal to +70 C. A low return temperature means that the house does not receive enough heat; overestimated - that energy bear superfluous expenses.

However, as is easy to see, the temperature difference between the flow and return flow is too large for normal heating operation. In this mode, the radiators on the supply risers will be overheated, and on the back, they will hardly provide apartments with heat.

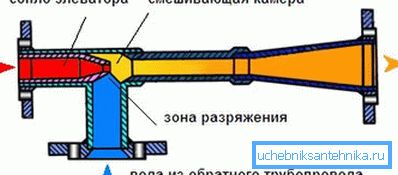

The problem is solved by the original design of the so-called elevator, or thermal unit. Its main unit, the elevator, is a tee with a nozzle inserted into it. Higher pressure and hotter feed water flows through the nozzle and draws some of the colder water from the return through the suction into the repeated circulation cycle.

Thanks to this subtlety in the circuit turns a large mass of water with a more stable temperature. Let us give one more temperature graph for the same range of street temperatures, but for the mixture that flows directly to the batteries.

| Street temperature, C | The temperature of the mixture, |

| +eight | 41.2 |

| 0 | 52.4 |

| -five | 58.9 |

| -ten | 65.3 |

| -15 | 71.5 |

| -20 | 77.5 |

| -25 | 83.5 |

| -thirty | 89.3 |

| -35 | 95 |

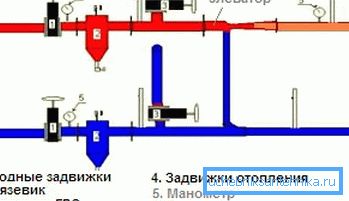

In addition to heating, the elevator unit provides the house with hot water.

In the old houses there were only two tie-ins of water supply:

- On flow (between the inlet valve and the elevator).

- On the return pipe (between the inlet valve and the suction).

Where the DHW is powered depends on the current supply temperature. At 90 ° C and below, hot water is withdrawn from the supply pipe, at higher temperatures - from the return.

The main drawback of such a scheme is that in the absence of water extraction, the water does not circulate, and before it is heated it is necessary to drain several tens of liters through the mixer.

In addition: towel warmers in old houses can only be heated when there is a water separation in the apartment. They open their eyeliner.

From about the 1970s-80s of the last century, the elevator nodes acquired circulation tap-ins: on the supply and on the return line, two DHW valves appeared. Modes of circulation from feed to feed and from return to return are provided with retaining washers on the flanges between the tie-ins. The diameter of the washer is about a millimeter larger than that of the elevator nozzle.

What the gauge shows

So what pressure in the heating system of a multi-storey building is considered the norm?

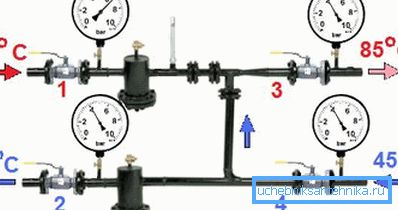

And what is happening at the same time in the heating main?

- In the summer, outside the heating season, the static pressure of the heating system corresponds to the height of the water column. For a ten-story building, it is approximately equal to 3 kgf / cm2, for a five-story building - 1.5 kgf / cm2.

- With open house valves and the normal operation of the elevator unit, the pressure in heating systems is almost equalized by the return pipeline and is normally equal to 3-4 kgf / cm2.

Allow, but in fact excessive pressure in the heating pipes is necessary for circulation in them. How so: the contour is leveled on an obratka, but all the same circulates?

Everything is very simple: after the elevator the manometer will show only 2 meters (0.2 atmospheres) more than on the return pipeline. Yes - yes, a drop of only 2 meters sets in motion the entire coolant in a huge house with hundreds of radiators.

And what about retaining washers? What difference is created on them?

Even less - from half a meter to a meter. And it is quite enough: because of the more complex configuration, the pressure loss in the heating system is much greater than in the DHW risers.

As for the highway, then for it during the heating season, approximately 8 atmospheres at the feed and 3 at the return line are considered the norm. However, the hydraulic resistance of the pipes and connected to the highway closer to the CHP of the house quench the differential, and the coolant can reach remote areas with parameters 6 / 3.5 and even 5/4 kgf / cm2.

Finally, the main question: why the pressure in the heating system? After all, when the system is full, the coolant will circulate in any case, will it not?

Not this way.

Without overpressure, the water column cannot rise above those 10 meters. In an apartment building above 3 floors, heating simply will not work.

In addition, there are a couple of subtleties.

- Sooner or later, the circuit will have to be dropped and filled. Without overpressure this is problematic.

- We must not forget about hot water. It is powered by the same heating mains. Without pressure, hot water will not get to the mixer.

Hot water supply

What pressure should be in the heating system - we seem to have figured out.

And what will the pressure gauge show in the DHW system?

- When cold water is heated by a boiler or a flow heater, the pressure of the hot water will be exactly equal to the pressure in the cold-water line minus losses to overcome the hydraulic resistance of the pipes.

- When powering the DHW from the return pipeline to the elevator in front of the mixer will be the same 3-4 atmospheres as on the return pipe.

- But when connecting DHW from the supply pressure in the mixer hoses can reach an impressive 6-7 kgf / cm2.

A practical consequence: when installing a kitchen faucet with your own hands, it is better not to be lazy and install a couple of valves in front of the hoses. Their price starts from one and a half hundred rubles apiece. This simple instruction will give you the opportunity to quickly shut off the water in case of a burst of hoses and not to suffer from its complete absence in the whole apartment during the repair.

Conclusion

We hope that our material will be useful to the reader. Additional information on how the heating system works, and what role pressure drops play in its work, can be found in the attached video. Successes!