Accessories for metal pipes - all you need for installation

Corrosion resistance, resistance to mechanical stress, low weight and ease of assembly allow the use of metal pipes for installation of heating systems and plumbing. Before you proceed directly to the installation is not superfluous will be familiar with the minimum set of components, without which it can not do.

Little about assembly technology

Regardless of whether the installation of water supply or heating systems, the assembly of metal pipes is performed in the following sequence:

- pipeline cut. The pipeline is supplied in coils, so you can not do without it. At this stage, you must especially carefully control the quality of the cut; there should be no burrs on the end;

- calibration - after working with scissors, it is necessary to restore the section geometry; this operation can be combined with chamfering;

- in fact, the connection will suit any of the most common fittings, for example, an American.

The better to cut the metal pipe

When the question arises, how to cut plastic pipes, special scissors can be considered the best option. Their blades allow you to get the perfect cut quality, without burrs and jams.

Note! If you simply press down on the scissors' handles, the material may flatten a little. To avoid this, the pipe must be rotated while cutting.

If there are no scissors at hand, then you can do with a regular hacksaw. However, in this case, the quality of the cut will be somewhat worse.

After the hacksaw will have to process the edges with a file. A common requirement for both options is the perpendicularity of the cutting plane of the longitudinal axis of the pipeline. Even a small bias can cause a joint failure in the future.

Pipe Calibration

Calibrator - the most important tool for metal pipes, which allows you to restore the shape of the section. Often when the pipeline is cut, its end is slightly deformed, and the calibration operation will allow it to become round.

You can select 2 types of calibrators:

- a tool that is intended only for restoring geometry and flaring;

- calibrator for metal pipes, which in addition to these operations allows you to immediately remove the chamfer.

As for the calibration technology, it is performed in the following sequence:

- A suitable nozzle diameter is selected and inserted into the pipeline. If the butt is deformed, then effort may be needed;

- after that you just need to rotate the calibrator, without removing the end of the pipeline from it, the blades of the knives will remove the chamfer at the right angle.

Pipeline installation

When a person thinks about how to work with plastic pipes, the most questions arise regarding the choice of connection.

There are many ways, each of them has its own advantages:

- push fittings. At the same time, the end of the pipeline is simply inserted up to the stop, for convenience, they even provide a viewing window. The disadvantage of this type of connection is quite a high price, and the joint itself is obtained one-piece;

- press fittings. This method of docking is used if necessary to connect metal-plastic with metal. In addition to the fitting itself, press pliers will also be needed. The tightness of the joint is achieved by the deformation of the metal. This type of joint is also considered one-piece;

- crimp fittings - the most common variant of the pipeline connection.

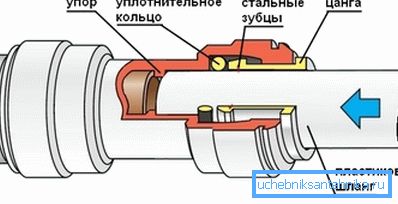

The collet fitting is one of the most popular types of crimp fittings, it provides both high strength and sufficient tightness of the connection, and if necessary, the junction can be easily disassembled. In addition, this fitting can be reused.

The device of such a connection is as follows:

- a cap nut and a compression ring are put on the pipe (the compression rings are also known as collets for metal-plastic pipes);

- then it is inserted into the fitting;

- the nut is tightly tightened, the collet is slightly deformed and tightly fixes the end of the pipeline.

Compared to other methods, it is detachable connections that are more popular. When using them, the question of how to disassemble plastic pipes is easily solved.

Note! When inserting a pipe into the fitting, it is not possible to put too much force on it, as this may damage the rubber seals. To facilitate the process end of the pipeline can be lubricated.

Separately, it is worth mentioning the connection using eurocone. The design allows it to be categorized as detachable, small differences lie only in the fitting device. A nut and a collet are put on the pipeline, then an eurocone for metal-plastic pipes is inserted into it, and the nut is tightened.

In addition, the installation will require fittings such as tees, crosses, adapters, allowing to connect different diameters, manifolds (for heating systems), corner fittings.

How to bend a plastic pipe

One of the advantages of metal-plastic is its flexibility, so you can do with a minimum number of fittings. For example, instead of installing a corner fitting, you can just slightly bend the pipeline itself. In the manufacture of such an element as a coil of metal-plastic pipes also can not do without bending.

The main problem with the deformation of the pipeline is that it can simply break. That is, its walls will converge at the bend, which will make impossible the normal circulation of the coolant.

This problem can be solved in two ways:

- using a pipe bender;

- bend the pipeline with your own hands. In this case, you have to fill the inner space of the pipe, to prevent fracture.

With manual bending, the pipe can be filled with sand or salt. It can replace the mandrel. After filling and sealing the hole at the ends, you can safely bend the pipeline.

Instead of bulk materials, a spring for metal pipes will be suitable. Its diameter should be only slightly smaller than the internal diameter of the pipe itself.

As for the benders, they can be classified by the method of bending:

- mandrel - a solid element moves inside the pipeline;

- segment - while bending is performed using a set of shoes for different diameters and bending radii.

In this case, the instruction for bending the pipe is simple - it is enough to simply apply an effort to the pipe bender lever. The pipe tightly pressed to the shoe and deformed.

Note! For any size there is a minimum bend radius. It can be determined by the formula 5 • D, where D is the diameter of the pipeline.

Manifolds for metal pipe

The collector is needed if the heating in the apartment is organized by the radial pattern. In this case, both the hot and the cooled coolant is supplied to the collector, and already from it goes the wiring to the radiators of the heating system (a separate supply and discharge pipe for each radiator).

By and large, a comb (or a manifold for metal pipes) is a pipe with outlets welded to it. If the budget allows, then collectors can be equipped with such elements as thermal heads and flowmeters.

In the case of maximum equipment you will need:

- Install flow meters on the feed comb. Thanks to this, it is possible at any time to change the volume of coolant supplied to each radiator separately;

- Thermal heads are installed on the collector with the "return". Sensors constantly monitor the temperature of the cooled coolant and can increase or decrease the size of the passage. Due to this, for example, during a cold snap, the size of the passage increases, and the coolant flow through the radiator increases accordingly.

The price of such a system can greatly exceed 10,000 rubles, so you can get by with a more modest option. In this case, plugs are left on the comb in order to retrofit the collector with temperature controllers or flow meters in the future.

Summarizing

Installation of metal-plastic pipeline - an easy task. But for this you will need a set of additional tools and fittings to ensure a tight and durable connection of pipes. The information in this article will provide a general impression of what is needed for laying the pipeline.

The video in this article shows an example of the connection of plastic pipes.