Adapters for pipes: how to arrange the connection of

Adapters for sewer pipes, water supply, heating, etc. are those elements without which the laying of communications would be impossible in principle. The list of tasks solved with the help of such products is almost limitless, and therefore we will provide below only the most important information on this topic.

Main varieties

First we need to understand the subtleties of terminology.

As a rule, any part that is used to connect two or more sections of the pipeline, or to connect valves, is called a fitting. In this case, the term "adapter" is usually called only those fittings that allow you to join pipes of different diameters.

So the conclusion can be made quite simple: all adapters belong to a group of fittings, but not every fitting can be called an adapter.

Note! In fact, such accuracy is characteristic only for professional literature. In practice, even specialists are mistaken in using these concepts, for example, when buying plumbing pipes and adapters in a store, it is necessary to specify exactly what you mean.

Adapters for sewer pipes, for water supply systems, etc. may have a different configuration. In the table below we give examples of the most commonly used types of such products:

| Adapter Type | Scope of application |

| Clutch | It is used to connect pipeline sections without changing direction, as well as to increase the length of the pipe. It is designed to ensure maximum tightness of the joint. Couplings, which are used to reduce the diameter, are often called reductions. |

| T-connector (tee) | It is mounted for the discharge from the main line of the section with a smaller diameter or for branching the pipeline into two sleeves. |

| Knee | Used to make turns at different angles. In this case, knees under different diameters are quite rare: usually such an installation is not practiced because of the risk of uneven distribution of pressure. |

| Cross | It has four exits, which can be located both perpendicularly and at different angles. It is used to form piping. |

Naturally, this is only the most general description. Other adapters for plastic pipes and fittings for metal communications can be found on the market, but they will perform approximately the same functions.

Features of selection and installation

For metal

When assembling metal pipelines for water supply and drainage, metal fittings are most often used. Usually they are made of steel (for cast iron systems - of cast iron), and to improve anti-corrosion properties they are coated with non-ferrous metals (chrome plating, nickel plating). Adapters from technological alloys, which primarily include bronze and brass, are also popular.

Note! Bronze and brass products last longer, but their price is higher than that of steel with various protective coatings.

According to the configuration, such products are distinguished:

- Models for welding or soldering. Welded varieties are usually mounted end-to-end, but those intended to be connected with a soldering iron are most often equipped with sockets at the ends intended for the installation of pipe segments.

- Adapters with elastic cuffs. Used in the installation of non-pressure systems, most often - in the sewer. Also according to this technological scheme, adapters for medium and large diameter ventilation pipes are produced, but their joint can be reinforced with an additional clamp.

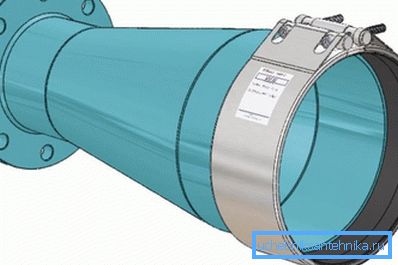

- Flange construction. They are used for equipment of large diameter pipelines, provide high reliability even with significant pressure.

Note! In a number of situations, combined models are used, in which a flange is installed at one end, and a nozzle for threading or welding is installed at the other end.

- Straight threaded connections (on an external or internal cone). Used for joining a variety of pipelines, complete with sealing gaskets and cap nuts fixing parts in the connected state.

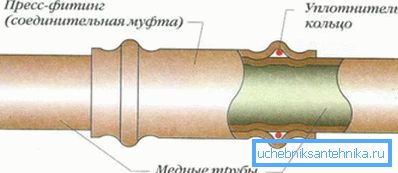

- Fittings for copper pipes for installation of press sleeves. Provide a fairly quick and reliable installation due to the use of special crimping. The disadvantage of such parts is the impossibility of dismantling without violating the integrity of the product.

For plastic

Plastic adapters for plastic pipes are also available in a fairly extensive range. They are characterized by less reliability than metal ones, but they are much cheaper, and they are much easier to assemble with your own hands.

Among the varieties can be identified:

- Polyvinyl chloride and polyethylene products for installation using rubber cuffs. Mounted without additional fasteners, fixation provides an inner elastic ring. Used in non-pressure sewage systems.

- PVC fittings for glue mounting. More reliable than previous, but also unable to withstand high pressure.

- Polymer threaded adapters. They are used relatively rarely because they are not capable of ensuring proper tightness under load. May apply in low pressure pipelines, in ventilation, etc.

- Adapters made of polypropylene, welded. Garnet a high level of reliability, but form one-piece connection. To work with such fittings, special soldering irons with sets of nozzles, the size of which corresponds to the diameter of the pipeline, are used.

- Metal and composite structures, which include plastic shells and steel (sometimes bronze or brass) fixing elements. This group includes crimp adapters for metal-plastic pipes, as well as combined fittings, with which you can arrange the transition "plastic-metal".

Tip! If the part does not have a socket, then the best adapter from a cast-iron pipe to a plastic one is just a press fitting.

The scope of these or those products is largely determined by the features of the system:

- Virtually any transitional elements can be used in the sewage system - the pressure inside the pipes is low, so that tightness can be achieved almost without effort.

- It will be somewhat more difficult with plumbing. Here the best methods of installation will be plastic welding, as well as the use of threaded connections with metal parts.

- For a hot water system, it is desirable to take composite materials reinforced with glass fiber or metal, since they are distinguished by a lower level of temperature deformation.

Conclusion

Adapters for PVC pipes, as well as fittings for products from other polymers and metals can have very different shapes and designs. At the same time, they should ensure the most reliable and tight connection of pipelines with different diameters, which is quite often required when laying communications.

The video in this article will help you understand the nuances of the selection and installation of these parts, so that before starting work should be given time to view it.