Centralizers for pipes: the choice and application

In this article, we will discuss how and why centralizers are used for pipe welding. In addition, we consider the design features of the most popular models from what is currently on the market. So, what is a centralizer and why is it needed?

Efficient way to make the weld seam even and tight

It is no secret that there are special devices adapted to perform a perfectly flat cross-section of pipes. But, even if the cut is made as smooth as possible, it will be practically impossible to combine both pipes with sections for high-quality welding.

As a result, the weld will be uneven and, as a result, the connection will not be tight. The solution to this problem can serve as an internal or external centralizer for pipes.

Features of operation

Both metal pipes, and their PPU analogs, before welding, must be leaned against each other as smoothly as possible so that there is no gap at the junction.

To make such a combination of slices with your own hands is almost impossible. Moreover, the combination of cuts is an order of magnitude more complicated with an increase in the diameter of the pipes. Therefore, during the assembly of sewer systems and other pipelines without the use of fittings for sewage, special centralizers are used.

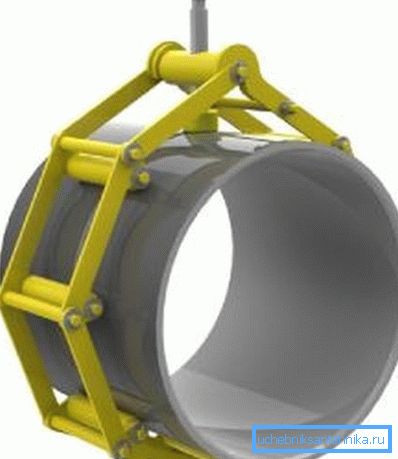

The device embraces the two pipes to be combined and allows them to be connected to each other as precisely as possible, fixing in this position. After welding is performed with guaranteed high quality weld. The device is then dismantled and the pipeline can be used for its intended purpose.

Main varieties

After we have decided on what the centering equipment is used for, consider the types of devices that are on sale.

All centralizers, which today can be purchased in the respective stores are divided into two main categories - internal and external.

- Devices of the external type are abbreviated as TsN and are intended for installation and use on the outside of pipes. Devices of this type, regardless of size, are easy to use, easy to install and produce fast and efficient centering. Devices of the external type are represented by a wide range of equipment (eccentric, link, hydraulic and other configurations).

- Internal centralizers are abbreviated to CV and are hydraulic installations.. Devices of this type from the inside are bursting the edges of the pipes, shifting their sections to each other. The advantage of the equipment is the possibility of using on pipes of different diameters.

Characteristics of individual modifications

After we have considered the features of the general classification, we will consider the characteristics of individual modifications of the centering devices.

- TsZN - centralized external centralizer is designed to combine the ends of the pipes with a joint diameter from 50 mm to 2 meters.

Important: Operation of devices is allowed in a wide range of ambient temperatures from - 40? С to + 40? С. The device constructively represents a polyhedron with lamellar links on hinged joints.

The coupler elements are combined by means of a screw mechanism.

- TsZN-G - the centralizer-unit external hydroficated is a modified version of the previous device. The essential difference of this modification from the previous one is the simplicity of operation and the absence of the need for the application of substantial physical effort. As a result, the process of combining welded elements is significantly accelerated without compromising the quality of the finished result. The device consists of lamellar links at the hinge joint, but not the screw mechanism, but hydraulics is used to set the links in motion. Admissible diameter of pipes fluctuates in the range of 720-2020 mm

- TsAN-G - centralized arched outer hydroficated is designed to work with a cross-sectional diameter of 325-820 mm.

The device is a detachable structure consisting of sections connected by hinges. The use of a device with such a design guarantees additional convenience when installed at the joint.

The device uses arcuate sections, which are compressed, adjusting the cuts of the joint. The number of arcuate sections is determined by the diameter of the pipes.

Each of the sections used is equipped with special stops that securely fix the elements to be combined, while ensuring optimum quality and tightness of the joint. Directly on the sections are fixed hydraulic actuators, designed for the maximum developed force up to 5 tons.

- The Central Scientific Center — an external chain-type centralizer is a device with a manual drive, designed to work with a cross-sectional diameter from 426 to 1420 mm.

In contrast to the linkage analogs, chain installations are capable of providing greater force during centering. Devices of this type can be used both in the construction and repair of pipelines.

Important: The chain structure is built using quick-detachable mechanisms, which has a positive effect on operating performance.

- TsNE - external eccentric centralizer is used to work with joints with a diameter of 89 to 426 mm.

The device consists of several gripping arcs, driven by an eccentric clamp. The device can, is used to work with pipes of different diameters by changing the axis of the eccentric or through the use of special spacers.

- TsV - centralizer of internal type hydraulic is designed to combine the ends of the swivel and non-rotary pipes.

The device, if necessary, not only combines the joints, but also gives them the most regular round shape. The use of such devices allows building pipelines using continuous automatic welding.

- CA - centralizer clamp is used to work with pipes of small diameter.

This property and reasonable price make the device the most popular among non-professional and novice collectors of pipelines. (See also the article Butt-Weld Pipe: Features.)

Conclusion

So, we examined what the centralizers are, what are their most popular varieties, and what is their application instruction. Based on this information, you can choose the device that will correspond to the features of the work being carried out.

More useful information you can find by watching the video in this article.