Choosing a tool for soldering polypropylene pipes

Master plumbers use a special tool for soldering polypropylene pipes, which is usually called a soldering iron, and which works on a network of 220V 50 Hz, which is quite acceptable for almost all industrial and residential buildings.

Modification of such devices may differ from each other in power, size, weight, and even appearance (flat and cylindrical), but, nevertheless, the principle of welding remains the same. Below we will make a short review of some models, consider the basic principles of working with them, and also show you the video in this article.

Soldering and Soldering Polypropylene

Tool overview

Note. In addition to the heating unit itself, the set for soldering polypropylene pipes also includes special nozzles of different diameters, which correspond to the standard cross-section of propylene pipes. Such elements can be of aluminum alloy, which can also be coated with Teflon. The last option is more expensive, but when working with Teflon PP does not stick, which facilitates the work.

- Electric soldering iron for soldering polypropylene pipes CANDAN SM-06 has a double heating element, that is, two 750 W heating elements, which allows you to save electricity during the waiting period, while at the same time keeping the tool hot. Unlike SM-01 and SM-03, on the modification of CM-06, you can use a nozzle with a diameter of not more than 40 mm, since here the heating part is somewhat narrowed, which in turn contributes to lower energy consumption.

- The set together with the unit comes with 4 paired nozzles for 20 mm, 25 mm, 32 mm and 40 mm, a metric tape measure, a level, a key for installing nozzles and scissors, and it all fits into a metal case. The thermostat of the soldering iron is designed for heating up to 300? C, but the maximum temperature is used extremely rarely. The unit can operate from a household electrical network of 220V 50 Hz, equipped with an automatic bag no less than 16A.

- CANDAN SM-04 soldering iron is more designed for welding pipes of large cross-section polypropylene, the heating part is made in the form of a disk, where there is only one hole for fixing the replaceable pair lining. The modification of SM-04 has a small mass, which increases not only the ease of transportation, but also increases the ease of operation in different positions, but at the same time, it is quite a powerful device with two heating elements of 1000W each, which allows you to save electricity in the waiting period while keeping the tool hot.

- The temperature range set by the thermostat can vary from 50? C to 320? C - this makes it possible to work in cold basements and outdoors in windy weather. The package also includes 3 nozzles for 50 mm, 63 mm and 75 mm, a metric tape measure, a level, a key for installing nozzles and a scissors, and it all fits into a metal case. But if necessary, the instruction allows you to additionally purchase pair nozzles for 20 mm, 25 mm, 32 mm, 40 mm, 90 mm and 110 mm - the power of the soldering iron will be enough

- Electric equipment for soldering polypropylene pipes Eral ER-01 (LUX) is used for welding polypropylene pipes and fittings with a diameter of 16 mm to 75 mm, has a total power of 1500 W, which is provided by two PETs of 750 W each. The heating part has a flat shape with three holes for fixing the pair of interchangeable nozzles, and a special stand allows the fixation of the unit, both in horizontal and in vertical position.

- The temperature range set by the thermostat can vary from 50? C to 320? C - this makes it possible to work in cold basements and outdoors in windy weather. The package also includes 4 nozzles for 20 mm, 25 mm, 32 mm and 40 mm, a metric tape measure, a level, a key for setting nozzles and a scissors, and all this fits into a metal case. But if necessary, it is possible to additionally purchase a pair of nozzles for 50 mm, 63 mm and 75 mm - the power of the soldering iron will be enough

- Electric machine for soldering polypropylene pipes of large cross section, the heating part is made in the form of a disk, where there is only one hole for fixing the interchangeable paired lining. The ER-03 version has a low mass, which increases not only the ease of transportation, but also increases the ease of operation in different positions, but at the same time, it is quite a powerful device with two heating elements of 1000W each, which allows you to save electricity in the waiting period while keeping the tool hot.

- The temperature range set by the thermostat can vary from 50? C to 320? C - this makes it possible to work in cold basements and outdoors in windy weather. The package also includes 3 nozzles for 50 mm, 63 mm and 75 mm, a metric tape measure, a level, a key for installing nozzles and a scissors, and it all fits into a metal case. But if necessary, the modification allows you to additionally purchase a pair of nozzles for 20 mm, 25 mm, 32 mm, 40 mm, 90 mm, 110 mm and 125 mm - the power of the soldering iron will be enough

- The electric device for soldering polypropylene pipes STURM TW-7218 is somewhat different from xiphoid soldering irons in its cylindrical shape, although it has the same periodic type of heating with a maximum temperature of 300? C. The power of this unit is 1880W, which allows it to operate from a household electrical network of 220V 50Hz, which is protected by an automatic 16A. unpaired nozzles, which are supplied from the manufacturer, have a Teflon coating, from which the price naturally increases.

- The heating time of the unpaired packing on the cylinder is 10 minutes at room temperature.. In addition to the soldering iron with a stand, the metal case also includes 3 unpaired attachments for 20 mm, 25 mm and 32 mm, a hex wrench and a screwdriver.

Pipe welding

Different polypropylene pipes are used for different temperatures of the water supply system, where a whole-wall pipe is used for cold water, PPR with aluminum reinforcement is used for hot water supply, and fiberglass is used as a reinforcing layer for heating.

It is believed that PPR with aluminum can withstand the temperature of water up to 90 C without deformation, but PPR with fiberglass can withstand up to 150C, but in hot water and heating the liquid usually does not heat up more than 80-85 C. Therefore, PPR is usually used as a hot option. with aluminum. (See also the article Polypropylene sewer pipes: features.)

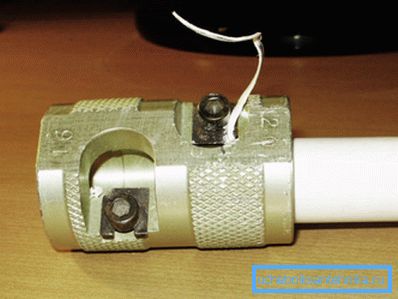

The reinforcing layer can be located in the middle of the polypropylene wall, but it can also be located closer to the top - it turns out that the heating nozzle will remove the PPR, stripping the foil, and this will lower the quality of the joint. To avoid such a problem, a trimmer is used, which clears the end of aluminum foil, but it is better to choose pipes with central reinforcement - this saves time.

Note. Most craftsmen prefer to work with aluminum foil pipe, using it also for cold water, since hot PPR has thicker walls.

In the top photo you see the steps of welding a polypropylene pipe with a soldering iron, but each of the moments requires a certain time. So, holding the pipe and fitting on the hot nozzle should last 5-10 seconds and the same time should be held in the hands of the connected node so that the solder can cool.

Conclusion

There are no limiters on paired and unpaired attachments, therefore, the depth of entry of the pipe and fitting is regulated by your own hands and should be no more than 15 mm. Otherwise, the end will rest against the septum of the fitting, which will make the pipeline passability lower.